Ali ste se kdaj spraševali, kako se v metale čevlje (v stolcu ali na igrišču, celo v biciklih) prorizejo luknje? To je odličen vprašanje! Danes bomo raziskovali stroje za prorizovanje čevljev; ponožite se v svet teh strojev, pridobite vpogled v to, kako poenostavijo in pospešijo proces ustvarjanja izdelkov podjetij. Cepivalna mašina od Vedette.

Ročno probivanje cevi je tudi počasno in se ne izvaja hitro. Poleg tega pa morda ni vsakič na istih mestih, kar lahko povzroči večje težave kasneje. Zato imamo napredne stroje za probivanje cevi, kot so odbojni stroj za bakrene cevke od Vedette. To so bile stroje s namenom izvajanja iste vrste dela, vendar hitreje, lažje in z enakimi rezultati.

Najnovejše stroje za pobijanje cevkov imajo številne dodatne funkcije, ki lahko vsak dan še bolj izboljšajo vašo delo. Na primer, nekateri stroji vam lahko pomagajo poravnati cevke in pobiti več cevkov hkrati. To bo še več ušilo vašega časa! Poleg tega lahko ti stroji spreminjajo hitrost in moč pobijanja glede na vrsto kovina, s katero delate. Zato lahko delate z kovinami brez nobenih težav. enoposredni odbojni stroj od Vedette. Nekateri stroji lahko vsebijo tudi orodja, ki lahko merijo in označujejo, kam naj bodo otroke. To vam bo veliko pomagalo, še posebej, če morate ustvariti edinstvene oblike za prilagojene naloge.

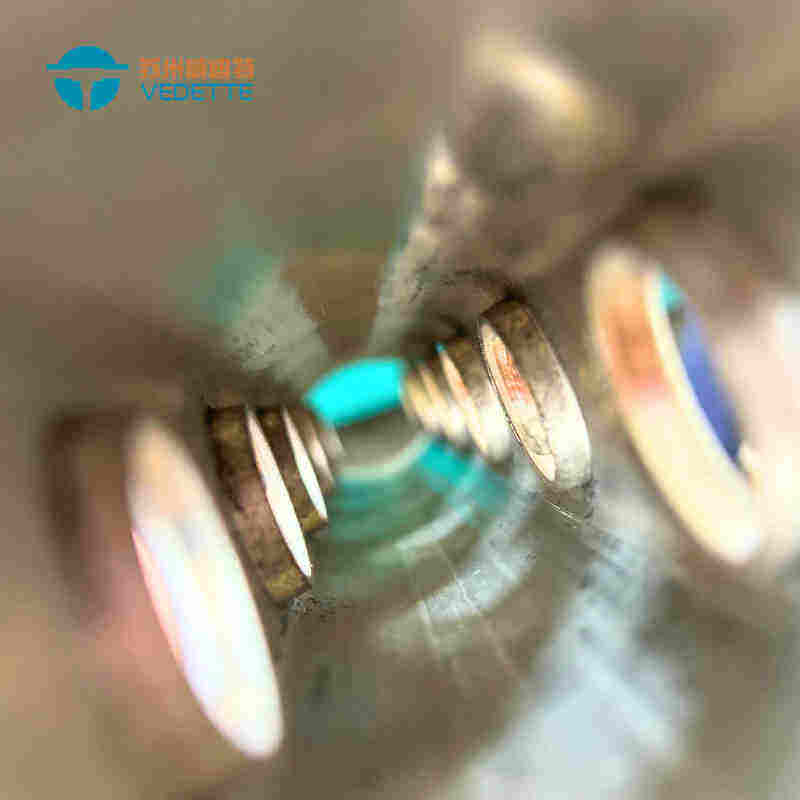

Stroji za pobijanje cevkov se lahko tudi uporabljajo za izdelavo številnih različnih izdelkov. Ti stroji, kot so Odbojni stroj za nerdzavo celico lahko pobijajo različne oblike in velikosti, zato ni potrebno kupovati številnih različnih strojev za vsakega od njih. To je mnogo praktičneje za podjetja, ker omogoča večjo fleksibilnost pri proizvodnji številnih različnih izdelkov.

Jih je mogoče vključiti v večje proizvodne linije ali delovati samostojno kot posamezno, samostojno delovno središče. Če jih uvedete v trenutni delovni tok, boste dokončali več opravil in proizveli hitreje / več izdelkov. Na ta način lahko vaše podjetje raste in omogoča možnosti za delo na drugih projektih brez najema dodatnih virov, zato izberite Odbojni stroj za večkraterice .

Suzhou VEDETTE, kot pomenjen proizvajalec opreme za obdelavo cev na trgu, pripisuje velik pomen tehnološkemu napredku ter raziskovalnim in razvojnim investicijam, ter nadaljuje z izdelovanjem novih produktov s konkurenčno močjo na trgu, da bi zadovoljili vedno spreminjajoče se potrebe trga. Postavljamo visoko kakovost življenja ter zadovoljstvo strank kot glavni cilj in ponujamo širok izbor visokokakovostnih storitev, vključno s predprodajno poročilo, tehnično podporo prodaje, poslejsko prodajno održavanje ter da bi zagotovili strankam dostop do profesionalne in časovno primernega tehničnega pomoči in rešitev. Naše produkte je mogoče uporabiti v različnih industrijah. Za uporabnike, ki jih zanimajo stroji za obdelavo cev, je Suzhou VEDETTE gotovo najbolj zanesljiva izbira.

Suzhou Vedette Industrial Equipment Co., Ltd., ustanovljena leta 2011, se nahaja v območju strokovnih naprav za odpiranje trub blizu jezera Taihu, inovacijskem središču v sektorju proizvodnje opreme. To je tehnološko napredna državna podjetja z več kot desetletjem izkušenj v raziskovanju, razvoju, proizvodnji in prilagajanju avtomatiziranih proizvodnih vrstic. V decembru 2022 je imela 31 uporabne modele in 10 patentov na opremo za izumove. Oprema je priljubljena tako doma kot tudi mednarodno, z strankami po vsem svetu. Podjetje sledi svoji misiji, da ponuja vredne produkte in storitve svojim strankam, in se posveča temu, da postane vodilna pri razvoju tehnoloških inovacij v področju obdelave trub v Kitajski.

Naša podjetja že več kot desetletje proizvaja opremo za avtomatizacijo obdelave cevi in imamo več kot 1000 dizajnov, ki niso tipični. Izkušeni prodajalci projekti bodo prilagodili storitve na podlagi temeljnega razumevanja potreb strank. Naša oprema je zasnovana in preskusena glede na proces zasnove projekta. Stranke lahko sledijo procesu sestavljanja in odpravljanja napak opreme v živo katerikoli čas. Ko bo oprema potrjena, izvedejo pregled izhoda v skladu z procesom dostave, da se zagotovi, da bo oprema hitro integrirana v proizvodne postopke fabrike stranke. Imamo popolnoma brezhiben sistem shranjevanja podatkov in opreme. Vse podatke o cevični opravi in opremi ter strankah ohranjamo v papirnih in elektronskih datotekah. Storitev posodabljanja matric uporablja risbe ali prilagoditev. Po prodaji pa ponujamo strokovno pomoč.

Da bi zagotovili stabilnost in kakovost v opremi za drcanje cev naših izdelkov, pridržujemo se predpostavke, da je najprej kakovost, ter izvajamo druge ukrepe, kot je nadzor izvora ter spremljanje procesa proizvodnje in stalno izboljševanje. V prihodnosti bomo še naprej pridrževali se načela, da je najprej kakovost. Nadaljevali bomo z izboljšovanjem kakovosti naših izdelkov in storitev, da ustvarimo večjo vrednost za stranke.