Ko je potrebno izdelati lukove v metalu, med najuporabnejšimi orodji je hidravlična lučarska presa. Pri tej se uporabi voda s visoko tlakovanjem, ki s močno silo vtisne luč v metal, zaradi česar pride do ukrivljanja listov. Ko je vaš udar nič več kot naključen poskus, kaj korist bo? Zavode uporabljajo Vedette hidravlične Cepivalna mašina lučarske prese za izdelavo vsega, od avtomobilske opreme do metalične nameštine. Te strojne enote so pomembne pri proizvodnji velikega števila izdelkov za vsakdanjo uporabo.

Na koncu želimo, da bi vsak delavec mogel izvajati postavitve tega vrste čim hitreje in enostavneje; zato obstajajo hidravlični preskovski lisaji. Ti very hitro in z visoko natančnostjo vrtijo luknje, zato ne izgubljajo časa, to je le ena od razlogov, zakaj bo delavec mogel narediti več dela v manjšem času. Te stroje so sposobne ustvariti te luknje skoraj takoj, zato namesto poenostavljene procese za vsako luknjo, jih dobite vse zelo hitro. Tudi porabljajo manjše energije kot mnogi drugi tipi strojev, hidravlični preskovski lisaji. To je tudi dobro za svet, in lahko podjetju shrani desetice tisoč na energiji. Vsi ti stroji so znatno ekološkejši, kar se prevede v korist ekologiji sveta in cene prevoza.

Razlog, da so hidravlični preskovski lisaji odlični — jih je mogoče uporabljati za širok obseg opravil, v različnih industrijah. Vedette Stroj za pobijanje in obočenje so tudi zelo versatilni, saj lahko ustvarijo - na podlagi vrste - več velikosti in oblik otvorov. Lahko ustvarijo tudi po meri izdelane oblike, kot so pravokotniki in trikotniki. Ponudba različnih velikostih otvorov je prednost za katere koli industrijo, ker je malo drugih strojev, ki bi bili tako prehodni in primereni za avtomobilsko industrijo, ki preskakuje otroke skozi težko ocel ali za proizvodnjo nameštja, ki izreza vzorce v šibkejših ligalih. Eden od razlogov, zakaj so hidravlične preskovne lisaje tako priljubljene v proizvodnji, je njihova versatilnost.

Podjetja bi morala izbrati stroje, ki so najbolj primerni za njihove posebne naloge, da bodo konkurenčnejša in dosegla boljše rezultate v hidravličnih odbojninskih lisah! Moramo si ogledati delo, ko ljudje delajo pravo velikost in značilnosti. Poleg tega potrebujejo veliko opreme in jim je treba, če želijo delavci vsakodnevno, da jih obvezno usposabljajo v zvezi s varnostnim delovanjem naprav. To omogoča delavcem, da uporabljajo odbojne lisave tako učinkovito, predpostavljeno, da imajo primerno usposabljanje in opremo. Kaj lahko podjetja dosežejo z uporabo visoke kakovosti hidravličnega odbojninskega lisa

Kot material je kovina ena največ uporabljenih v masovni industriji; zato prispeva k zanesljivim, zaupanja vrednim strojev. Hidravlični odbojni lisi so zelo veliki in močni, stroj Vedette Izdelki sama bo trajala še mnogo let z udarami, ki lahko bodo različnih vrst. To storitveno omogoči strojevskim enotam, da so zanesljive za podjetja, ko je potrebno opraviti delo, kar lahko pomeni katerokoli število stvari v današnjem času. To je ključno, ker jim omogoča, da izdelajo odlične produkte v osnovnem primeru s dolgim repom tveganja, da se stroji pokvarijo ali bodo stalno potrebovali ohranjanje.

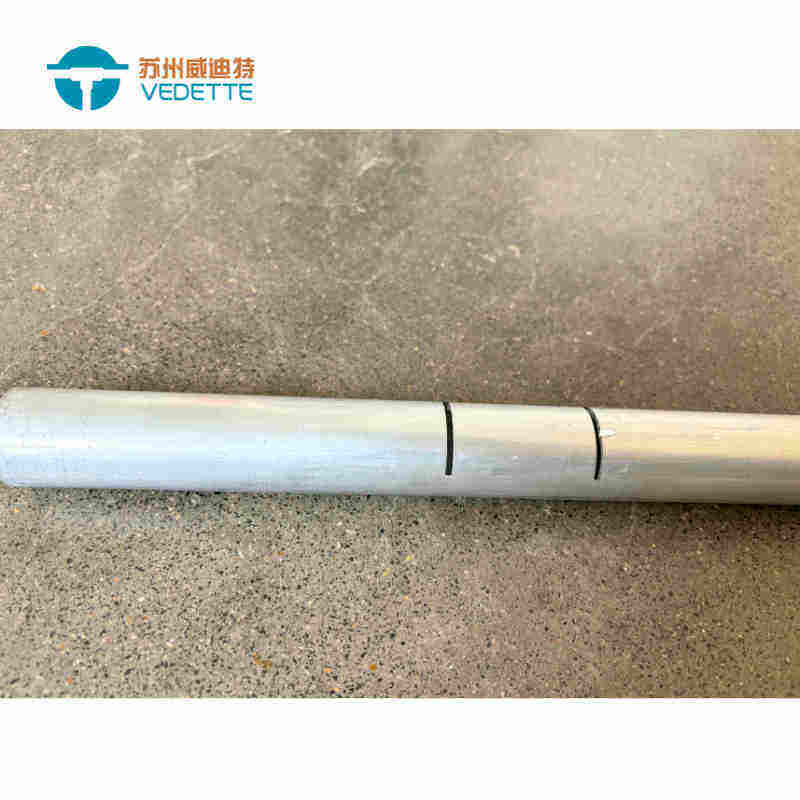

Suzhou VEDETTE je vodilni proizvajalec opreme za obdelavo cevi v sektorju hidravličnih čepovalnic. Poudarja pomembnost tehnološke inovacije, raziskave ter razvoja in je predstavil konkurenčne nove produkte, ki sledijo spreminjanjem potreb trga. Postavljamo kakovost življenja ter izkušnje strank kot jedro naše dejavnosti in ponujamo polno spekter profesionalnih storitev, vključno s prodajno poročilo, tehnično podporo in poslovnico po prodaji, da zagotovimo, da bodo stranke imeli korist od profesionalne in časovno primernega tehničnega pridobitka in rešitev. Naše produkte lahko uporabite v širokem obsegu aplikacij, da izpolnijo potrebe različnih industrijskih sektorjev za obdelavo cevi. Suzhou VEDETTE, vodilni proizvajalec opreme za obdelavo cevi, je najboljša možnost za uporabnike.

Hidraulična štampna presa bo vedno ohranjala kakovost naših izdelkov kot glavno točko, tako da zagotovimo, da nadzorujemo izvorno proizvodni postopek, spremljanje, stalno izboljšanje izvora itd., da bi se zagotovila visoka kakovost in trajnost izdelka. V prihodnje bomo nadaljevali z upoštevanjem tega načela in bomo stalno izboljševali naše izdelke in storitve, da bomo ponujali večjo vrednost strankam.

Podjetje za hidraulične štampne lisaje proizvaja avtomatizirano opremo za obdelavo cevi že več kot 10 let in imamo več kot 1.000 dizajnov, ki niso konvencionalni. Ko popolnoma razumemo zahteve naših strank in zahteve, lahko izkušena prodajna ekipa prilagodi storitve naše ponudbe po vaši meri. Postopek planiranja projekta sledi pri izdelavi in odpravljanju naše opreme. Stranke lahko vsakodnevno spremljajo postopek sestavljanja in odpravljanja opreme v spletnem načinu. Po tem, ko stranka sprejme opremo, izvedejo izhodne preglednosti povsem v skladu z postopkom izhodne dostave, da se zagotovi, da bo oprema hitro vključena v proizvodne naloge na fабriki stranke; Imamo popoln sistem arhiviranja podatkov in opreme. Oprema stranke je shranjena tako v elektronskih kot tudi papirnih datotekah. Posodabljanje form lahko ponudi ilustracije ali prilagojenost. Podpora posle prodaje jo zagotavljajo naši izkušeni tim.

Suzhou Vedette Industrial Equipment Co., Ltd., je bila ustanovljena leta 2011 in se nahaja v jugozahodni del Sužoua, blizu hidrauličnega šlagarskega stroja, inovačnega centra v proizvodnji hidrauličnih šlagarskih strojev. To je visokotehnološka družba, ki ima več kot desetletje izkušenj v raziskovanju, razvoju, proizvodnji in prilagajanju avtomatiziranih proizvodnih linij. Ob svojem izdaju v decembru 2022 je imela 31 uporabne modele in 10 patentov na izobretev, povezanih s stroji. Njegovo opremo so doma in tuj pričakovali z zadovoljstvom, saj ima stranki po vsem svetu. Družba sledi svoji osrednji misiji, da zagotavlja kakovostne izdelke in storitve strankam, ter se posveča bitju voditeljske v tehnološkem napredu pri obdelavi cevi v Kitajski.