VAI KAD esat domājis, kā metāls pārvēršas par lietām, ko mēs redzam sev apkārt katru dienu? Metālam nav nepieciešams pēc smaga darba un speciālām mašīnām, lai veidotu šo metālu ir visbrutālākaisLineārsIzkārtojums ar elastīgu izliekumu jūsu viedoklis nevajadzīgi atsperforma. Šīs funkcijas veikšanai ir nepieciešama hidrauliskā liekšanas iekārta, kas ir patiešām nozīmīgs agregāts, ko varat izmantot. Šī Vedette vara cauruļu caurumošanas mašīna ir lielisks rīks, kas iespiež šķidrumu, lai izveidotu metālu visās dažādās līknēs.

Tas ir precīzāks par mehānisko liekšanas mašīnu. Dators programmē mašīnas kustības, kas strādā ar metālu. Citiem vārdiem sakot, iekārta var saliekt metālu tieši tur, kur vēlaties to saliekt. Un tas bieži vien milimetros. Dators sniedz mašīnai norādījumus par to, cik liels spiediens jāpieliek, kādā virzienā var mainīties un kad tai jāapstājas. Vedette viena vārpstas štancēšanas mašīna Precizitāte ir ļoti svarīga, lai garantētu, ka metāls iegūst pareizu formu un atbilst specifikācijām.

Metāla ražošanā hidrauliskās liekšanas mašīnas parasti izmanto metāla ražošanas procesā. Vedette Perforēšanas un vilkšanas mašīna nozīmē, ka viņi palīdz izgatavot metāla izstrādājumus no savām izejvielām. Lietas, ko mēs redzam un lietojam ikdienā, piemēram, automašīnas, lidmašīnas vai ēkas, tiek izgatavotas ar metāla izstrādājumu palīdzību. Iespējams, ka svarīgāka ir hidrauliskā liekšana, jo tā padara ģeometrijas grūti vai neiespējamas izveidot, izmantojot citas iekārtas. Ne tikai tas, bet arī hidrauliskā liekšana patērē mazāk enerģijas nekā citas metodes, kas var ievērojami ietaupīt izmaksas.

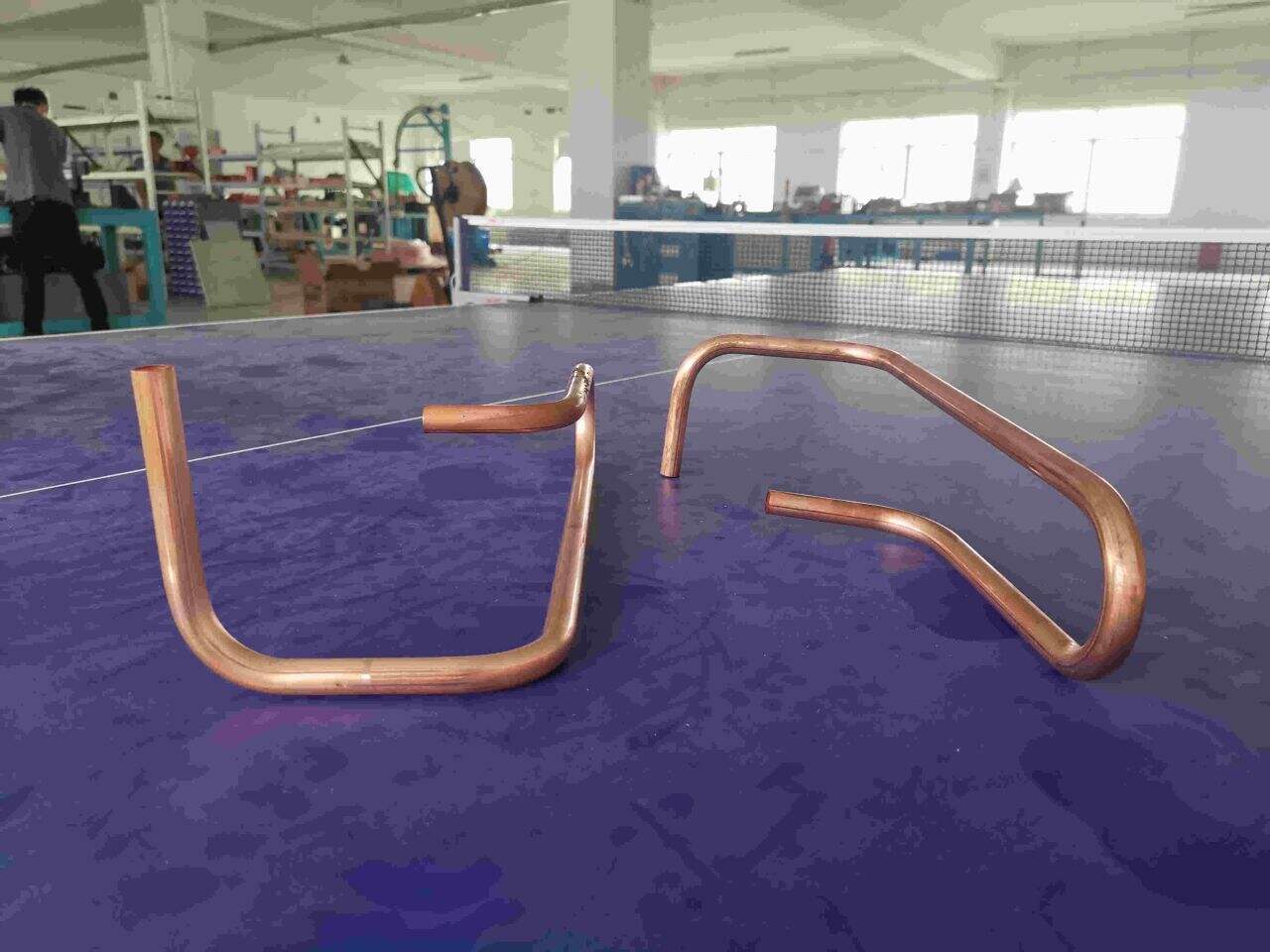

Universāls: viena no labākajām lietām hidrauliskajās liekšanas mašīnās ir tā, ka tās ir ļoti elastīgas. Jūs varat saliekt metālu tik daudzās formās. Daudzvārpstu štancēšanas mašīna padara tos par lielisku iespēju pasūtījuma metālapstrādei un citiem projektiem, kuriem nepieciešams unikāls dizains. Metāla strādnieks var izmantot hidraulisko liekšanas mašīnu, lai izveidotu nepāra formas, noteikta izmēra automašīnas daļu. Turklāt tie darbojas arī ar citiem krāsainiem metāliem, piemēram, alumīniju, tēraudu, kā arī varu. Šī daudzpusība padara tos piemērotus daudziem projektiem.

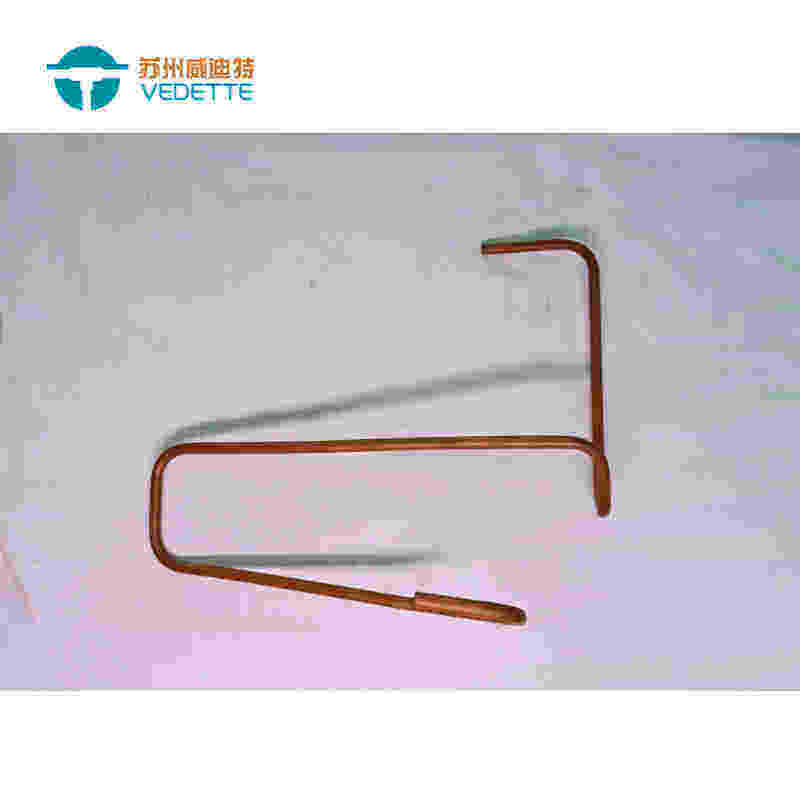

Nepieciešams, lai metālstrādniekam būtu detalizēts projekts, ko viņi vēlas izgatavot, lai viņi varētu izmantot šāda veida liekšanas mašīnu kā hidraulisko. Pēc konstrukcijas uzstādīšanas iekārtā uzmanīgi tiek nolaists metāla gabals. Ar noteiktu spēku hidrauliskā prese saspiež, lai tā iegūtu formu, kā parādīts attēlā. Gatavojoties lietošanai, metālapstrādes darbinieks ar specializētiem instrumentiem izpilda galīgos darbības plānus šajā daļā. Nerūsējošā tērauda cauruļu caurumošanas mašīna Tas var būt ārkārtīgi atalgojošs darbs, lai gan tikai daži ļoti prasmīgi cilvēki, kas potenciāli palikuši uz šīs planētas, varēs veiksmīgi iemācīties labi saliekt metālu, izmantojot tehnoloģiju.

Lai nodrošinātu produktu kvalitātes izcilību un stabilitāti Mēs ievērojam pirmo kvalitātes principu un veicam citus pasākumus, piemēram, avota kontroli, ražošanas procesa uzraudzību un hidrauliskās liekšanas iekārtas uzlabošanu. Nākotnē mēs vispirms ievērosim kvalitātes principu. Mēs turpināsim uzlabot mūsu produktu un pakalpojumu kvalitāti, lai nodrošinātu klientiem lielāku vērtību.

Suzhou Vedette Industrial Equipment Co., Ltd. tika dibināta hidrauliskajā liekšanas mašīnā gleznainajā Taihu ezerā Sudžou dienvidrietumos un ir galvenais tehnoloģisko jauninājumu centrs iekārtu ražošanā. Ar vairāk nekā desmit gadu pieredzi cauruļu apstrādes iekārtu izstrādē, izpētē un ražošanā, kā arī dažāda veida automatizētām ražošanas līnijām, tas ir nozīmīgs valsts augsto tehnoloģiju uzņēmums, kas nodarbojas ar tehnoloģiski progresīvu, automatizētu, un uzlabotas iekārtas. Uz 2022. gada decembri uzņēmumam pieder 31 lietderības modeļa patents, kā arī 10 iekārtu izgudrojumu patenti. Tās iekārtas ir augsti novērtētas gan Ķīnā, gan visā pasaulē ar daudziem klientiem.

Suzhou VEDETTE ir vadošais cauruļu apstrādes iekārtu ražotājs šajā nozarē. Tas liek lielu uzsvaru uz hidraulisko liekšanas iekārtu, izpēti, kā arī izstrādi, un ir laidusi klajā jaunus produktus, kas ir konkurētspējīgi, lai apmierinātu pastāvīgi mainīgās tirgus prasības. Mēs esam apņēmušies sniegt jums ekspertu pakalpojumus, kas ietver konsultācijas pirms pārdošanas un pārdošanas tehnisko atbalstu un pēcpārdošanas pakalpojumus. Tas nodrošinās, ka klienti saņem ātrus un efektīvus risinājumus. Mūsu produktus var izmantot visdažādākajās nozarēs. Lietotājiem, kam nepieciešams aprīkojums cauruļu apstrādei, Suzhou VEDETTE neapšaubāmi ir visuzticamākā izvēle.

Mūsu hidrauliskā liekšanas iekārta ir ražojusi cauruļu apstrādes automatizācijas iekārtas vairāk nekā 10 gadus, un mums ir vairāk nekā 1,000 netradicionālu dizaina plānu. Pēc rūpīgas mūsu klientu vajadzību un prasību izpratnes mūsu pieredzējusī pārdošanas komanda pielāgos pakalpojumus. Mūsu iekārtas tiek ražotas un atkļūdotas atbilstoši projekta plānošanas procesam. Klienti jebkurā laikā var tiešsaistē pārraudzīt aprīkojuma montāžas un atkļūdošanas gaitu. Kad klients ir pieņēmis iekārtu, viņš veiks izvešanas pārbaudi saskaņā ar izvešanas piegādes procesu, lai nodrošinātu, ka iekārtu var ātri ievietot klienta rūpnīcas ražošanas procesā. Mums ir efektīva aprīkojuma un datu uzskaite. Visi dati par aprīkojumu un klientiem tiek glabāti papīra failos, kā arī elektroniskajos failos. Veidņu atjaunināšanas pakalpojumu var izmantot, lai izveidotu rasējumus vai nodrošinātu pielāgošanu. Pēcpārdošanas palīdzību nodrošina mūsu profesionālā komanda.