Vai jūs jebkad esat domājuši par to, kā tiek izgatavotas metāla caurullas? Metāla caurullas ir būtiskas struktūru, piemēram, namiem un tilpniem, celšanai, ko mēs redzam katru dienu. Dažām struktūrām nebūtu nekādas vērtības vai drošības bez šajām caurullām. Šeit ietveras Vedette Griešanas mašīna ir vieta, kur ietveras CNC caurulju dēļu segšanas mašīna.

CNC nozīmē Datora Numeriskais Kontrols, kas ir tas, kā dators vadījums tiek lietots mašīnā. Tas nozīmē, ka mašīna var paveikt savu darbu ar ļoti augstu precizitāti un efektivitāti. CNC pipu dūrēšanas mašīna ir rīks, kas var palīdzēt veidot caurumus metāla pipās daudz ātrāk un vienkāršāk. Pirms CNC mašīnu ieviešanas darbinieki bija spiesti dūret katru caurumu pašiem. Šis Vedette taisnas celmas griešanas mašīna bija garš un strādātspējīgs process ar nepietiekamu precizitāti. Caurlaužas tika veidotas nepareizajos vietos. Tagad caurulu veidošana trūkst mazāk laika un ir precīzāka. CNC caurulu veidošana var papildus nodrošināt, ka caurulēs tiek izveidotas pareizajos vietos. Mašīna tagad var radīt caurulu pareizajā vietā, iespaidoja cauruleni. Tas taupa laiku un ļauj visiem paveikt savu darbu labāk. * Izdarīsim to precīzi katru reizi. CNC caurulu veidošanas mašīnas ir ļoti noderīgas, jo nodrošina, ka caurulēs tiek veidotas pareizajos vietos ikkatrā reizē. Dators komandē mašīnu, tāpēc mašīna izdara cauruleni pareizajā vietā. Tas ir noderīgs, veidojot griestus vai tilptus.

Ja vēlaties sasniegt vairāk rezultātu mazāk laikā un izveidot komponentus ātrāk nekā jebkad iepriekš, tad kāpēc neizmantot CNC cauruma dēļu mašīnu. Tā kā mašīnas var turpināt strādāt bez pārtraukumiem, ap tām tiek veiktas citas svarīgas uzdevumi, savukārt dēļos veidojot caurumus. Tas taupīs laiku un naudu uzņēmumiem, kas var ražināt vairāk dēļu ātrāk. Labi, Vedette Vienu/dviņu bezklipu šķērsošanas mašīna jo mašīna var darīt visu paša un nav vajadzīgi tik daudzi operatori, lai to vadītu. Tas taupīs uzņēmumiem naudu un nodrošina, ka strādnieki var koncentrēties uz citiem uzdevumiem, kas prasa viņu uzmanību.

CNC dēļu caurumu mašīna padara šo procesu vēl vieglāku. iespēja veidot sarežģītus formas un dizainus, kas citādi ir grūti vai nemazziegami rokām. Tā kā tai ir datorsatvara, mašīna var kustēties ar lielu precizitāti un pat veidot caurumus sarežģītos modeljos. Durvis, ko tas Četrcauruļu bezklipšu griezšanas mašīna tehnoloģija atver celtniecības un dizaineru prasībām iedomāties kreatīvus veidus, kā varētu būt uzbūvētas ēkas (un citas struktūras). CNC mašīnas ļauj darbiniekiem materializēt savas inovatīvās dizainu idejas realitātē, kas agrāk nebija iespējams.

Bez tam, CNC caurdeļu sula ir būtiska metāla caurulēm ražošanai. Tas padara darbu vieglāku un ļauj darbiniekiem katru reizi izveidot ideālas caurules. Ar vienu klikšķi mašīna arī ietaupa laiku uzņēmumiem, kas ir liels uzvaras punkts strādnieku pasaulē. Turklāt, kops tubu dēļa cirtmašīna tā nodrošina darbiniekiem iespēju radīt konfigurācijas, kas agrāk varbūt nebūtu bijušas sasniedzamas citos sistēmas veidos. Jo modernāka tehnoloģija mums ir pieejama, jo labāks kļūst celtniecības procesa uzlabojums un atjauno entuziasmu par to, kā varētu būt uzbūvēti objekti celtniecības nozarē.

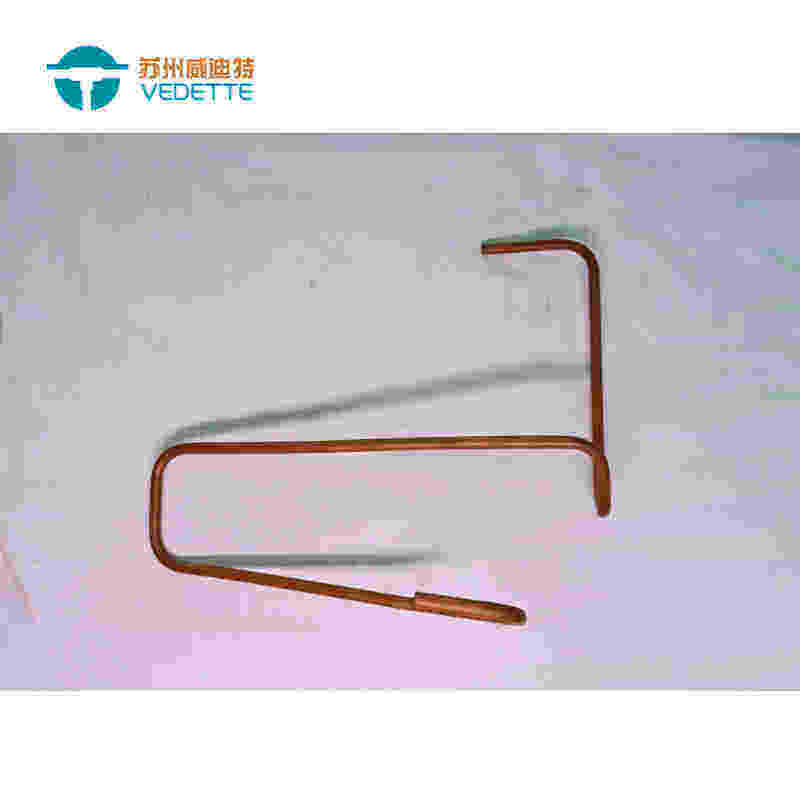

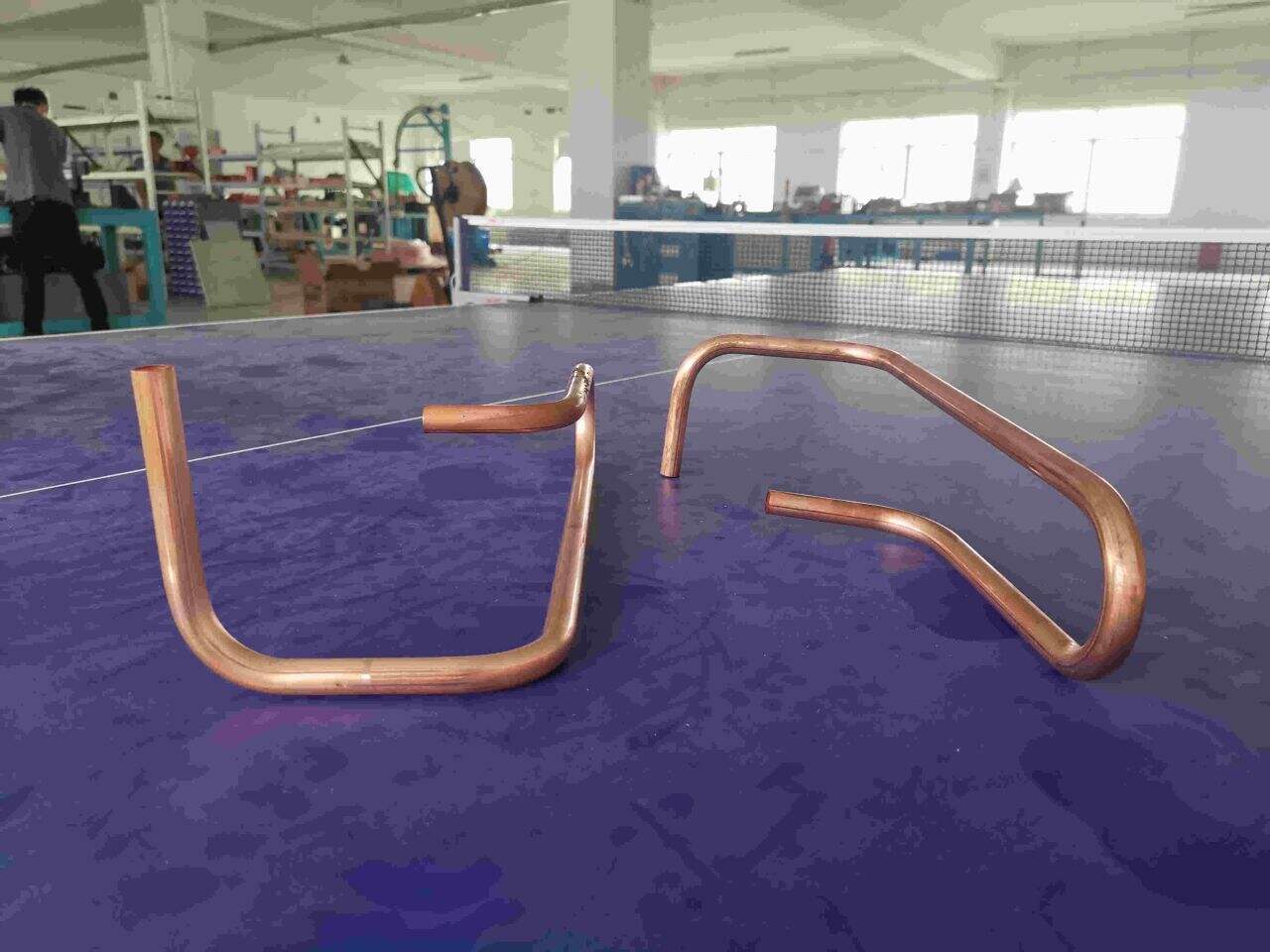

Mēs esam vienotais piegādātājs, kas nodrošina iekārtas piparu apstrādei, piedāvājot plašu iekārtu izvēli, lai atbilstu jūsu prasībām. Vairāk nekā 10 gadus mēs koncentrējamies uz piparu apstrādes automatizācijas iekārtu jomu un esam spējuši piedāvāt vairāk nekā 1 000 nenumeriskos dizaina risinājumus. Pieredzētas pārdošanas projektu komandas veiks pielāgotus pakalpojumus pēc detalizētas analīzes par klienta prasībām. Mūsu iekārtas tiek ražotas un attīstītas saskaņā ar Cnc piparu cauruma mašīnu. Montāžas un derīgās pārbaudes procesu klienti var redzēt tiešsaistē jebkurā brīdī. Kad iekārta tiek akceptēta, tika veikta striktā izceļošanas inspekcija saskaņā ar procesu, lai iekārta varētu ātri integrēties klienta ražošanas uzdevumos. Mums ir drošs datu un iekārtu sistēmas arhīvs. Visas klientu iekārtas informācijas tiek saglabātas gan papīra, gan elektroniskā formātā. Formas atjaunošana var sniegt ilustrācijas vai pielāgošanu. Pēc pārdošanas pakalpojumus nodrošina mūsu profesionālā komanda.

Cnc caurulu dēļu pūšanas mašīna vienmēr turpinās uzturēt savu produktu kvalitāti par galveno, nodrošinot ražošanas procesa uzraudzību, avota kontroles pastāvīgu uzlabošanu un citus aspektus, lai garantētu augstu kvalitāti un ilgtspēju. Nākotnē mēs turpināsim sekot šai principam un uzlabot savus produktus un pakalpojumus, lai nodrošinātu lielāku vērtību klientiem.

Suzhou VEDETTE, kā viena no vadošajām Cnc caurulņu dēļa cirtšanas mašīnu ražotājām tirgū, piešķir augstāko nozīmi tehnoloģiju inovācijām un pētījumu un attīstības investīcijām, turpinot ieviest jaunas produktu linijas, kas atbilst tirgus arvien dažādākiem prasību. Mēs uztveram kvalitāti kā dzīvesveidu, un mūsu galvenais mērķis ir klientu apmierinātība, sniedzot visu profesionālo servisu kopumu, ieskaitot pirmspārdošanas konsultācijas, pārdošanas tehnisko atbalstu, pēcpārdošanas servisu, un nodrošinot, lai klienti saņemtu laicīgu un profesionālu tehnisko palīdzību un risinājumus. Mūsu produkti var tikt piemēroti dažādiem nozarēm. Suzhou VEDETTE, kas ir liela caurulņu apstrādes aparātu ražošanas uzņēmums, ir ideālais izvēles variants tiem, kam tas nepieciešams.

Suzhou Vedette Industrial Equipment Co., Ltd. tika izveidota 2011. gadā un atrodas pie skaistās Taihu ezera dienvidurietēs no Suzhou, kas ir svarīgs tehnoloģiskās inovācijas centrs attiecībā uz iekārtu ražošanu. Tas ir augstas kvalitātes valsts uzņēmums, kuram ir vairāk nekā 10 gadu pieredze jomās, kas saistītas ar pētījumiem, attīstību, ražošanu un automatizēto ražošanas līniju pielāgošanu. Kas attiecas uz Cnc caurulu dēļa cirtmašīnu, tas bija 31 noderīgā modeļa un 10 ierīču patenta īpašnieks. Tās iekārtas tiek augsti novērtētas gan Ķīnā, gan ārpus tās, ar daudziem klientiem.