Jeste li ikada se pitali kako se metalki cijevi (u stolici ili na igralištu, čak i u biciklima) dobiju otvore na njima? To je dobar pitanje! Sada ćemo istraživati strojeve za probijanje cijevi; upustite se u svijet ovih strojeva, saznajte kako funkcioniraju kako biste pojednostavili i ubrzali proces stvaranja proizvoda u tvrtkama s Stroj za probijanje od Vedette.

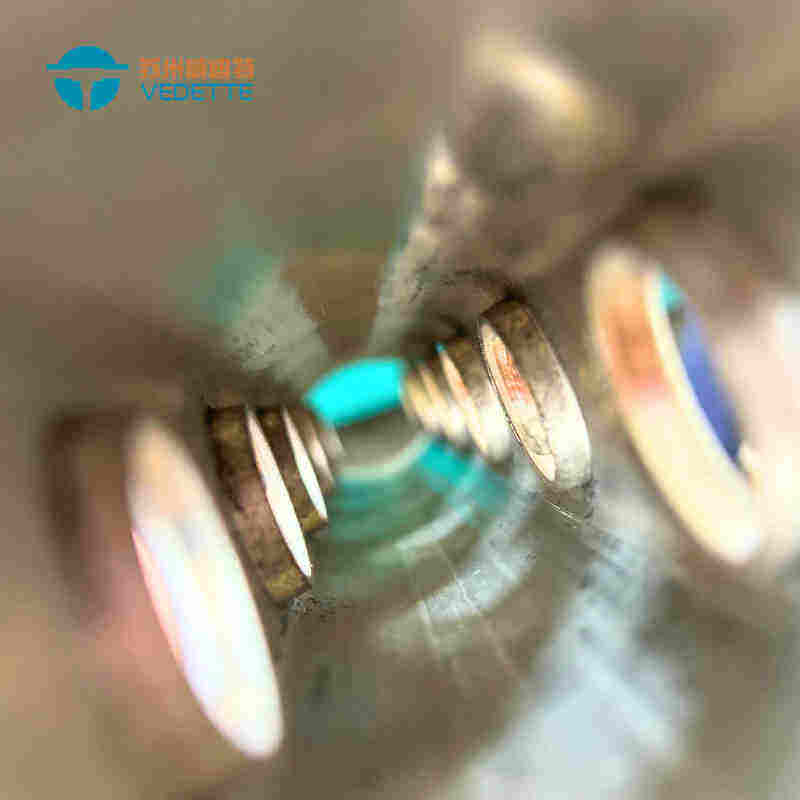

Ručno određivanje otvora u cijevima je sporije izvršiti. Također, otvori mogu biti svaki put na drugačijim mjestima, što može uzrokovati veće probleme kasnije. Zbog toga imamo napredne strojeve za određivanje otvora u cijevima kao što su stroj za otvaranje otoka u bakarnoj cijevi od Vedette. To su strojevi koji imaju namjeru obavljati istu radnju brže, lako i konzistentno.

Najnovije strojeve za probijanje cijevi imaju mnoge dodatne značajke koje mogu činiti vaš rad još boljim svakodnevno. Na primjer, neki strojevi vam mogu pomoći prilagoditi cijevi i probiti više cijevi istovremeno. To će vam štiti još više vremena! Također, ovi strojevi mogu mijenjati brzinu i jačinu probijanja ovisno o vrsti metala koju koristite. Stoga možete raditi s metalima bez ikakvih problema koristeći stroj za otvaranje otoka s jednim valjem od Vedette. Neki strojevi također mogu uključivati alate koji mogu mjeriti i označiti gdje trebaju biti rupe. To će vam pomoći puno, posebno ako morate stvoriti jedinstvene dizajne za prilagođene poslove.

Strojevi za probijanje cijevi također se mogu koristiti za izradu mnogobrojnih različitih proizvoda. Ovi strojevi poput Stroj za otvaranje otoka u nerđajućoj cijevi mogu probiti različite oblike i veličine, pa nemorate kupovati mnogo različitih strojeva za svaki od njih. Mnogo je praktičnije za tvrtke jer pomaže biti fleksibilnije kada je riječ o proizvodnji mnogobrojnih različitih proizvoda.

Mogu se uključiti u veće proizvodne linije ili funkcionirati samostalno kao zasebni radni centar. Ako ih uvedete u trenutačni poslovni proces, moći ćete završiti više zadataka i proizvesti brže / više stavki. Na taj način će vaš posao moći rasti i omogućiti priliku da radite na više projekata bez dodavanja novih resursa, pa izaberite Stroj za višestruko otvaranje otoka .

Suzhou VEDETTE, kao promineni proizvođač opreme za obradu cijevi na tržištu, stavlja naglasak na tehnološki napredak te ulaganje u istraživanje i razvoj, te neprestano lansira nove konkurentne proizvode koji zadovoljavaju promjenjive potrebe tržišta. Postavljamo visoku kvalitetu života i zadovoljstvo kupaca kao glavni cilj, pružajući širok spektar kvalitetnih usluga, uključujući savjetovanje prije prodaje, tehničku podršku tijekom prodaje, održavanje nakon prodaje kako bismo osigurali kupcima profesionalnu i vremenski pouzdanu tehničku pomoć i rješenja. Naše proizvode mogu se primijeniti u različitim industrijskim granama. Za korisnike koji trebaju opremu za obradu cijevi, Suzhou VEDETTE je sigurno najpouzdanija opcija.

Suzhou Vedette Industrial Equipment Co., Ltd., osnovana 2011., nalazi se u blizini jezera Taihu, inovacijskom centru u sektoru proizvodnje opreme. To je tehnološki napredna nacionalna tvrtka s više od 10 godina iskustva u istraživanju, razvoju, proizvodnji i prilagođavanju automatskih proizvodnih linija. U prosincu 2022., posjedovala je 31 korisnička izumiteljska prava i 10 patenata za opremu. Oprema je popularna kako na domaćem tako i međunarodnom tržištu, s kupcima širom svijeta. Tvrtka se drži svoje misije pružanja vrijednih proizvoda i usluga svojim kupcima i poštovanja angažmana biti vodeći izumitelj tehnoloških inovacija u oblasti obrade cijevi u Kini.

Naša tvrtka proizvodi opremu za automatizaciju obrade cijevi već više od 10 godina, a imamo preko 1000 dizajna koji nisu tipični. Iskusni prodajni projektnici prilagođit će usluge temeljem detaljne razumijevanja potreba kupaca. Naša oprema je projektirana i testirana prema procesu dizajna projekta. Kupci mogu pratiti proces montaže i uklanjanja pogrešaka opreme online bilo kada. Kada se oprema odobri, provesti će ispitivanje izlaza prema postupku dostave izlaznog materijala kako bi se osiguralo da se oprema brzo može integrirati u proizvodne procese tvornice kupca. Imamo savršeni sustav čuvanja podataka i opreme. Svi podaci o opremi i kupcima za perforiranje cijevi čuvaju se u papirnim mapama i elektroničkim datotekama. Usluga ažuriranja štampa se može koristiti za crtanje skica ili prilagođavanje. Poslijeprodajna pomoć je dostupna putem našeg tima stručnjaka.

Da bismo osigurali stabilnost i kvalitet u opremi za probijanje cijevi naših proizvoda, držimo se pretpostavke da je kvalitet na prvom mjestu i provodimo druge mjere poput kontrole izvora te nadzor procesa proizvodnje i stalnog unapređivanja. U budućnosti nastavit ćemo držati se principa da je kvalitet na prvom mjestu. Nastavit ćemo poboljšavati kvalitet naših proizvoda i usluga kako bismo stvorili veću vrijednost za naše klijente.