Kas sulle kunagi ei kukenud, kuidas lähevad metallitubidesse (eesliides või mänguväljal, isegi jalgrattades) need reed? Hea küsimus! Tuba reetmootorid on täna teema, mida uurime; lase end neid masinaid maailmasse veenda, et saada ülevaade nende toimimisest, mis lihtsustab ja kiirendab ettevõtete toote loomise protsessi koos Lõikumasmootor vedettelt.

Tubade käeega löömine saab samuti aeglaselt teostada. Lisaks võivad need olema igakord erinevates kohtades, mis võib põhjustada suuremaid probleeme edaspidi. Seetõttu pakume me tänapäevased tube lööjemasinad nagu kuivide punktreffimismasina vedette'i poolt. Need olid masinad, mille eesmärk oli sama töö kiiremini, lihtsamalt ja konstantsemalt teha.

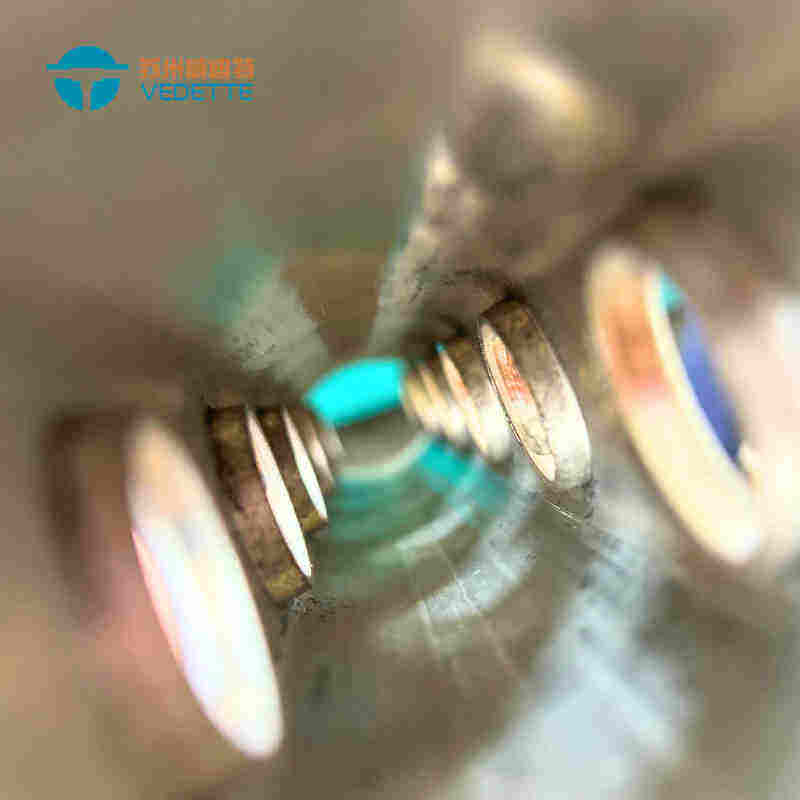

Uusimad rööpkõrvemootorid omavad palju täiendavaid funktsioone, mis võivad teie tööd igapäevast veelgi paremaks muuta. Näiteks mõned masinad aitavad teil joondada oma rööpe ja puhvastada mitmeid rööpe korraga. See säästab teil veelgi rohkem aega! Lisaks võivad need masinad muuta kiirust ja jõudu, millega nad puhvastavad, sõltuvalt kasutatavast metallitüübist. Seega saate metallitega töötada ilma probleemidega kasutades üheks teljeks mõeldud lõigamismasina vedette tooteid. Mõned masinad võivad kaasa tuua tööriistu, mis võivad mõõta ja märgita, kus on vaja looke tegemist. See aitab teil väga palju, eriti kui peate looma unikaalseid disainisid tellimusülesannete jaoks.

Rööpkõrvemootorid võivad ka kasutada mitmesuguste toodete valmistamiseks. Need masinad nagu Rohaline teraspuu lõikamismasin võivad puhvastada erinevaid kuju ja suurusi, nii et teil ei pea ostma mitmeid erinevaid masinaid iga ühe jaoks. See on palju mugavam ettevõtetele, kuna see aitab olla paindlikumal, kui tuleb paljude erinevate toodete tootmise osas.

Nad võivad olla integreeritud suuremate tootmisjuhtimissüsteemidega või tegutseda eraldi, kui sõltumatu töökeskus. Kui need lisada praeguse töövoo, siis saab rohkem ülesandeid edasi anda ja toota kiiremini / rohkem tooteid. Nii saab oma ettevõte kasvada ja avada võimalusi teha rohkem projekte ilma, et tuleks lisaresursse palkata, seega vali Mitmete puhvritega lõikamismasin .

Suzhou VEDETTE, mis on tugev jooksu töötlemise seadmete tootja turul, pannakse rõhku tehnoloogilise arengu ja uurimis- ja arendustegevuse investeeringutele ning jätkab konkurentsivõimas uue toote turuletoomisega, et rahuldada muutuvaid turu nõudeid. Me paneme esikohale kvaliteedi ja klienti rahulolu ning pakume ulatuslikku kvaliteetset teenust, sealhulgas e-müügi konsultatsioone, müügi tehnilist toetust ja pärastmüügihoidlust, et tagada klientidele professionaalne ja ajakohane tehniline abi ja lahendused. Meie tooted levinud erinevates tööstusharudes. Kasutajatele, kes vajavad jooksu töötlemise seadmeid, on Suzhou VEDETTE kindlasti kõige usaldusväärsem valik.

Suzhou Vedette Industrial Equipment Co., Ltd., asutatud 2011. aastal, asub röördepistamise seadmete tootmise innovatsioonikeskuses, mis on Tiuhu järve lähedal. See on tehnoloogiliselt eduka rahvusvaheline ettevõte, mis on suunatud üle 10-aastase kogemusega uurimisse, arendusse, tootesse ja automatiseeritud tootmelineeringute kohandamisse. Detsembris 2022 oli tal 31 kasuliku mudeli patendit ja 10 seadmete väljavaateid. Seadmed on populaarsed nii kodumaal kui ka rahvusvaheliselt ning nende klientide hulka kuulub terve maailm. Ettevõte järgib oma missjonit pakkuda klientidele väärtuslikke tooteid ja teenuseid ning on pühendunud olema juhtivaks tubade töötlemise seadmete tehnoloogiliste innovatsioonide arendamisel Hiinas.

Meie ettevõte on üle 10 aasta jooksul tootnud toru töötlemise automatiseerimise seadmeid ja meil on üle 1000 mitte tavalist disaini. Kogemuste kaupmeisted projekteerivad teenuseid, põhjustades klientide vajaduste sügavat mõistmist. Meie seadmed on projekteeritud ja testitud vastavalt projektidesigniprotsessile. Kliendid saavad jälgida seadmete kokkupanekut ja silumisprotsessi võrgus igal ajahetkel. Seadmest loetuses korraldatakse väljastamise protsessi vastavalt väljastamise protsessile, et tagada seadmete kiire integreerimine klientide tööstuslike tootmisprotsessidesse. Meil on täiuslik andmete ja seadmete hoidkeem. Kõik toru lõigamisseadmed, mis puuduvad seadmete ja klientide kohta, säilitatakse paberfailides ja elektronsetes failides. Mustrite uuendamise teenus võib kasutada sketsade tegemiseks või kohandamiseks. Pärastmyygi abi pakub meie spetsialistide tiim.

Et tagada stabiilsus ja kvaliteet meie toodete Tube punching seadmes, järgime kvaliteedi esmaks pannu põhimõtet ja rakendame teisi meetmeid, nagu allikate kontroll ning tootmisprotsessi jälgimine ja pidev parandamine. Tulevikus jätkame kvaliteedi esmaks pannu põhimõtte järgimist. Jätkame oma toodete ja teenuste kvaliteedi tõstmist, et luua klientidele suuremat väärtust.