Torusid kasutatakse lugematutes tööstusharudes ja töökohtades, nii et nende valmistamine on esmatähtis ülesanne. See hõlmab metalltorude vormimist erinevatel kujunditel, nagu painded, kumerused ja väänded. Vanasti tegid koolitatud käsitöölised seda käsitsi oma ainulaadsete oskuste ja tööriistadega, et moodustada nõutud kujundid. Kuid nüüd, CNC-tehnoloogia tulekuga, on nende torude tootmise tase palju parem ja kiirem. Gaasi aurukatel: Arvutite arvjuhtimine. See omakorda tähendab arvutite kasutamist, mis aitavad juhtida masinaid, mis töötavad kiiremini ja täpsemalt. Järgmises ajaveebis uurime, kuidas Vedette CNC torude valmistamine muutis meie võimet torusid valmistada ja aitab erinevates sektorites.

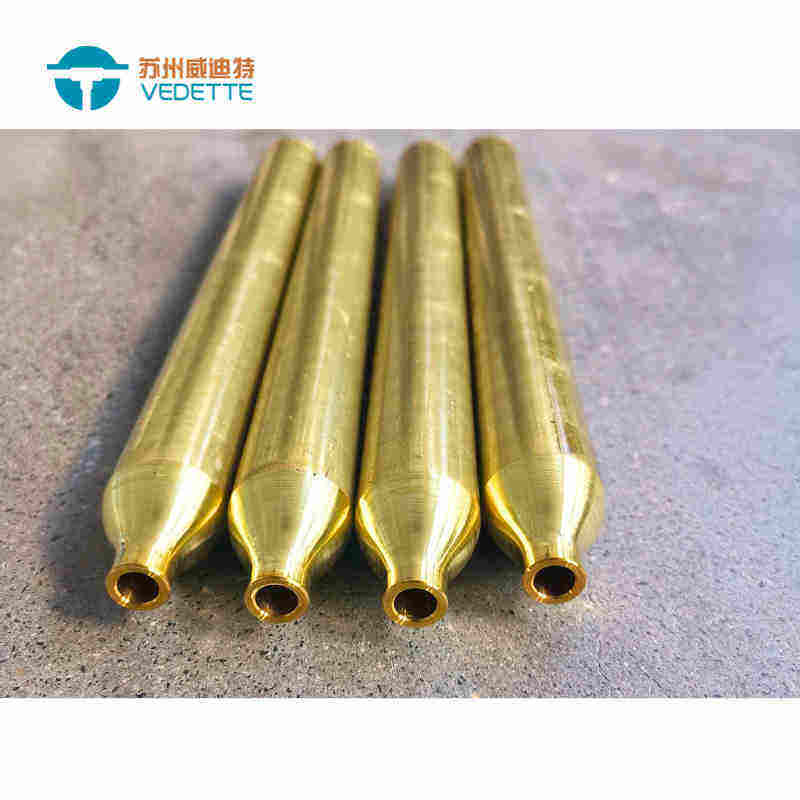

Leiutis on Vedette CNC torude valmistamine ja see tähendab lihtsalt, et saame valmistada torusid just sellise suurusega, nagu nad peavad olema. Seda ei saanud käsitsi teha enne masinate enda kasutamist, kuna need võivad torusid nii mitmelgi viisil väänata ja kõverdada, mida tavalised inimesed palja käega teha ei saa. Oleme kohanemisvõimelised ja võimelised valmistama täppistorusid, mis vastavad kõikidele spetsifikatsioonidele, mida klient otsib. Tegelikult kõrgsurve aurugeneraator saab kasutada mitut tüüpi materjalidega alates terasest kuni alumiiniumi ja vaseni. See mitmekülgsus sobib suurepäraselt igat tüüpi töödeks erinevates tööstusharudes, nagu lennukid või autod, ja isegi haiglad, kus on väga spetsiifilised torustikuvajadused, kui ohutus ja jõudlus on üliolulised.

Vedette CNC-torude valmistamisel on mõned hämmastavad omadused, mis muudavad väga suure täpsusega torud väga hästi keerukate detailidega. Need CNC-masinad on võimelised tootma ülidetailseid ikkesid ja ülaosasid, mida aastaid tagasi oleks olnud võimatu mitmel erineval viisil valmistada. Eriti plaanides, mis peavad olema vähem või täpsemad. Pealegi, tööstuslik aurugeneraator on oma kõrge korratavuse tõttu digitaalse tootmise üks tuntumaid aspekte. See tagab, et nad suudavad toota samu ülemise riiuli torusid ikka ja jälle, mis pole alati lihtne, kui kogu töö teeb hoopis inimkäed. Lisaks on see ühtlus väga oluline konkreetsetes tööstusharudes, kus sisendmaterjal vajab kvaliteetse tulemuse saavutamiseks suurt stabiilsust ja tugevust (lõpprakendus).

Tänu Vedette CNC masinatele toodetakse torusid kiiremini ja odavamalt. Need on loodud töötama katkematult nädalaid või aastaid. Teisisõnu, nad suudavad toota rohkem torusid lühema ajaga kui töötajad, kes teevad sama tööd käsitsi. CNC-masinad töötavad tõhusalt ka tänu sellele, et nad saavad lõigata erineva suurusega torusid, mis välistab vajaduse, et tootjad ehitaksid mitu masinat, üks iga suuruse kohta. See võib neid torusid tootvatele ettevõtetele oluliselt säästa raha. Lisaks on vaja vähem inimese sekkumist väike aurugeneraator, vähendab see tööjõukulusid ja muudab kogu protsessi veelgi odavamaks.

Vedette CNC torude valmistamine pakub teile kvaliteetseid torusid kiirelt ja täieliku täpsusega. Neid uskumatuid masinaid saab kasutada 24 tundi ööpäevas, seega suudavad nad torusid torude järel valmistada vaid lühikese ajaga. Samuti suudavad nad ühe toiminguga sooritada arvukalt painutusi ja kõverusi, säästes sellega mõlema materjali kulu. Stabiilne jõudlus elektriline aurukatel tööstuslik garanteerib, et iga toru vastab kõrgele kvaliteedile ja see on ideaalne klientidele, kes on ka vastupidavuse taseme suhtes tähelepanelikud. See usaldusväärsuse mudel on kriitilise tähtsusega iga ettevõtte jaoks, mis peab oma tootes omama väga kõrgetasemelist perspektiivi.

Oleme torutöötlemisseadmete tarnija, pakkudes teie vajaduste rahuldamiseks erinevaid CNC-torude vorminguid. Oleme torude töötlemise automatiseerimisseadmete valdkonnas töötanud rohkem kui 10 aastat ja meil on üle 1,000 disainilahenduse, mis ei ole standardsed. Meie müügiprofessionaalid on kogenud ja oskavad kohandada lahendusi, mis põhinevad klientide vajaduste põhjalikul mõistmisel. Meie seadmed on projekteeritud ja silutud vastavalt projektiplaanile. Montaaži ja silumise protsessi saab klient igal ajal veebis näha. Kui klient on seadmed vastu võtnud, viib ta läbi väljumiskontrolli vastavalt väljumise kohaletoimetamise protsessile, et tagada seadmete viivitamatu integreerimine kliendi tehase tootmisprotsessidesse. Meil on tõhus andmete ja seadmete arhiveerimissüsteem. Kliendi andmetehnika säilib nii dokumentides kui ka paberkandjal. Vormi värskendamine võib pakkuda visandeid või kohandatud. Meil on asjatundlik müügijärgne teenindusosakond ja saame pakkuda müügijärgset puhastust ja hooldust.

2011. aastal asutatud Suzhou Vedette Industrial Equipment Co., Ltd. asub Suzhou edelaosas Taihu järve vahetus läheduses, mis on seadmete tootmise sektori innovatsioonikeskus. See on kõrgtehnoloogiline riiklik ettevõte, millel on rohkem kui kümneaastane kogemus uurimis-, arendus-, tootmis- ja automatiseerimisliinide kohandamisel. 2022. aasta detsembris turuletoomise ajal oli sellel 31 kasulikku mudelit ja 10 seadmete leiutiste patenti. Seadmed, mida see toodab, on kõrge CNC-toru, mis moodustub nii Hiinas kui ka kogu maailmas ning millel on palju kliente.

Suzhou VEDETTE on CNC-toru moodustav torude töötlemise seadmete tootja. See paneb suurt rõhku tehnoloogilisele innovatsioonile, teadus- ja arendustegevusele ning toob turule uusi tooteid, mis on konkurentsivõimelised, et vastata turu pidevalt muutuvatele vajadustele. Usume, et meie peamine eesmärk on elukvaliteet ja klientide rahulolu, et pakkuda teile täielikku valikut professionaalseid teenuseid, mis hõlmavad nii müügieelset konsultatsiooni kui ka müügitehnilist tuge müügijärgset hooldust, et tagada klientidele juurdepääs kiire ja tõhus tehniline tugi ja lahendused. Meie tooted hõlmavad laialdast rakendust erinevate torude töötlemise tööstusharude nõuetele. Suzhou VEDETTE, tuntud torutöötlusseadmete tootja, on kasutajatele parim valik.

Tootekvaliteedi stabiilsuse ja kvaliteedi tagamiseks järgime esmalt kvaliteedi kontseptsiooni ning astume ka muid samme, nagu allikate CNC torude moodustamine, tootmisprotsessi jälgimine ja pidev täiustamine. Jätkame lähitulevikus kvaliteedi-kvaliteetpõhimõtte järgimist ning jätkame oma toodete ja teenuste täiustamist, et pakkuda klientidele suuremat väärtust.