Millal sa viimati tehases ringi käisid? Kui olete, oleksite võib-olla üllatunud, kui nägite suuri mehaanilisi manipulaatoreid, mille robotkäed liiguvad metalltorusid ühest kohast teise. Need imelised masinad on Vedette Toruotste vormimismasin ja need moodustavad suure osa tootmisprotsessist, nimelt sellest, kuidas valmistati nii palju tooteid, mida me iga päev kasutame.

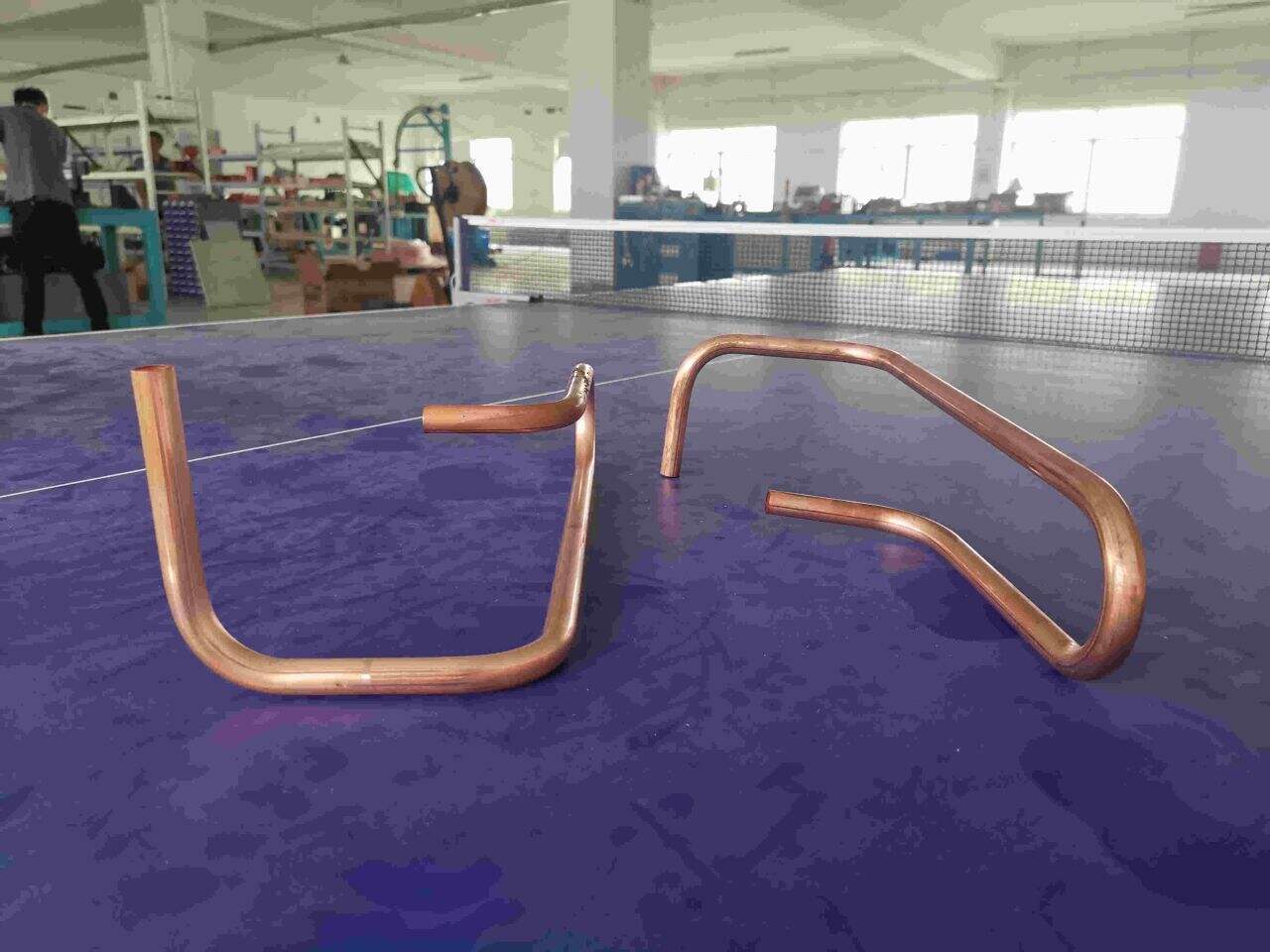

Kes teadis kaasaegse inseneri imesid, selle tulemuseks on CNC-torude painutusmasinad. See avaldab märkimisväärset jõudu - kas hüdraulilist või elektrilist jõudu, olenevalt konkreetsest kasutatavast süsteemist -, et veenda torusid täpselt sinna, kuhu nad tahavad. Teisisõnu suudavad nad korduvaid osi painutada ikka ja jälle täpselt samamoodi, ilma vigadeta või väheste vigadeta. See on põhimõtteliselt seda tüüpi korduv painutamine, mis võib tootmistingimustes nii hästi toimida.

Inimesed, kes neid masinaid kasutavad, on kõik kõrgelt koolitatud spetsialistid. Vedette Mitme jaamaga toru otsamasin kasutatakse suure hulga toodete valmistamiseks, mis aitavad hoida autosid teedel ja haiglates. Töötajad peavad pöörama suurt tähelepanu detailidele, sest isegi üks viga võib rikkuda terve partii ja aidata kaasa raiskamisele, tekitades tööandjale lisakulusid.

Vedette'i toodavad paljud ettevõtted Nelja toruga laastuta lõikemasin; kuid mitte kõik ei paku samal tasemel oskusi ja on pälvinud austust teistes tööstusharudes, nagu teatud teised. Need tippettevõtted uuendavad end pidevalt, et tarnida oma masinaid täpsemal ja tõhusamal viisil.

Teiste eesmärk on kavandada masinaid, mis võivad töötada mis tahes tüüpi torudega, mis annab neile palju paindlikkust. Kohandatud masinaid ehitavad teised, kes keskenduvad selliste seadmete ehitamisele konkreetse tööstusharu jaoks, olgu see siis auto- või kosmosetööstus. Erinevat tüüpi masinaid tootvad tipptootjad pakuvad oma klientidele iga juhtumi puhul uudseid ja tõhusaid lahendusi.

CNC toru painutusmasinad on väga kiired, mis muudab töö kiiremaks ja selle üheks suurimaks eeliseks. Varem painutasid töötajad iga toru käsitsi, mis võttis palju aega ja vaeva. Kuid mitme toru painutamine ühe arvutijuhtimisprotsessiga ja seetõttu oluliselt kiirem on võimalik ainult CNC tüüpi masinates. See säästab palju aega ja suurendab tootmist.

Suzhou VEDETTE on juhtiv Cnc-torude painutusmasinate tootja, kes toodab torude töötlemise seadmeid selles valdkonnas. See paneb suurt rõhku tehnoloogilisele innovatsioonile, teadusuuringutele ja arendustegevusele ning on turule toonud uusi tooteid, mis on konkurentsivõimelised, et vastata turu pidevalt muutuvatele nõudmistele. Oleme pühendunud teile asjatundlike lahenduste pakkumisele, mis hõlmavad nii müügieelset nõustamist kui ka müügitehnilist abi ja müügijärgset tuge. See tagab, et meie kliendid saavad kiireid ja tõhusaid lahendusi. Meie tooted on laialdaselt kasutatavad erinevates tööstusharudes. Suzhou VEDETTE, mis on suur torude töötlemise seadmete tootja, on kasutajatele parim valik.

Tootekvaliteedi järjepidevuse ja tipptaseme tagamiseks Oma toodete kvaliteedi ja stabiilsuse tagamiseks lähtume esmalt kvaliteedi eeldusest ja seejärel võtame kasutusele lisameetmed, nagu tootmisprotsessi kontrolliva allika kontroll ja pidev täiustamine. Järgime edaspidi kvaliteeti-kvaliteetpõhimõtte põhimõtet ning täiustame oma tooteid ja teenuseid, et pakkuda klientidele Cnc-toru painutusmasinate tootjaid.

Pakume torude töötlemiseks vajalikke seadmeid ühest peatusest, pakkudes teie vajadustele vastavaid masinaid. Oleme CNC-toru painutusmasinate tootjad torude töötlemise seadmete automatiseerimise valdkonnas juba üle 10 aasta ja meil on peaaegu 1,000 disainilahendust, mis ei ole standardsed. Kogemustega müügispetsialistid saavad teenuseid kohandada pärast kliendi nõudmiste üksikasjalikku mõistmist. Meie seadmed on projekteeritud ja silutud vastavalt projekti ajakavale. Kliendid saavad seadmete kokkupanekut ja silumist igal ajal veebis jälgida. Kui seadmed on heaks kiidetud ja kontrollitud, viivad nad läbi väljumiskontrolli, järgides rangelt väljumise tarneprotseduuri, et tagada seadmete viivitamatu kaasamine kliendi tehase tootmisülesannetesse; Meil on täiuslik andmete ja seadmete salvestussüsteem. Klientide kasutuses olevate seadmete andmed säilitatakse nii paberfailides kui ka elektroonilistes failides. Vormi värskendamine annab visandid või kohandatud. Meil on kõrge kvalifikatsiooniga müügijärgne teenindusosakond ja saame pakkuda müügijärgset puhastust, hooldust ja puhastust.

Suzhou Vedette Industrial Equipment Co., Ltd. asutati 2011. aastal ja asub kauni Taihu järve ääres Suzhou edelaosas, mis on seadmete tootmise tehnoloogiliste uuenduste keskus. Üle kümne aasta pikkuse kogemusega torutöötlusseadmete ning erinevat tüüpi eritellimusel projekteeritud automaatika tootmisliinide arendamise, uurimise ja tootmise alal on see üleriigiline kõrgtehnoloogiline ettevõte, mis tegeleb tehnoloogiliselt automatiseeritud ja keerukad seadmed. 20. aasta 2022. detsembri seisuga oli tal 31 kasuliku mudeli patenti ja 10 seadmetega seotud leiutise patenti. Selle seadmed on riiklikult ja rahvusvaheliselt hästi vastu võetud, teenindades kliente kogu maailmas. Ettevõte järgib oma korporatiivset eesmärki pakkuda kvaliteetseid tooteid ja teenuseid, mis lisavad klientidele väärtust, ning on pühendunud CNC-torude painutusmasinate tootjate torutöötlusseadmete tehnoloogilise arengu teerajajaks saamisele.