Automaatne nurgapuhastusmasina on eriline kategooria masinadest, mis pakuvad suurt abi erinevate materjalide servade ümardamisel ja puhastamisel. Nurgapuhastuse protsess tähendab lihtsalt serva puhastamist. Serva nurgapuhastamine on protsess, milles me seda natuke häiritame, et see näeks paremat välja ja oleks vähem lõigu ohtlik. Vedette'i automaatne nurgapuhastusmasin on sellise tugeva ja tõhusa üksuse näidis sellest tegevuse jaoks. See on spetsiaalselt disainitud mitte ainult toodete välimuse parandamiseks, vaid tagab ka kvaliteetse lõpptulemuse.

Siin on nurgapuhastus oluline protsess paljudes tööstusharudes ja tootmiskeskustes. Automaatse nurgapuhastusmasina kasutamine aitab sul säästa aega ja jõudu ning tagab, et tooted näevad märkimisväärelt välja. Enne võttis manuaalne nurgapuhastamine väga palju aega, et kõik täiuslikuks saada. Siiski, automaatse juhtmeebeldi kallastamine , saate teha mitmeid vaid mõne minutiga. See tähendab suuremat tehasse tootmiskoguse ja efektiivsemate tehasi.

Autaatne nurgapuhastusmasin parandab ka toodete kvaliteeti. See suudab teha täpselt ühtlasi sirged servad. See on hea viis, et toode näeks tugev välja, ja see jääb alati positiivselt mõjutama igas ettevõttes. Kvaliteet hoiakse kõrge tasemel, olenemata sellest, kes masinat kasutab. See on suur pluss, sest see võimaldab hoida klientide tahtvat kvaliteeti.

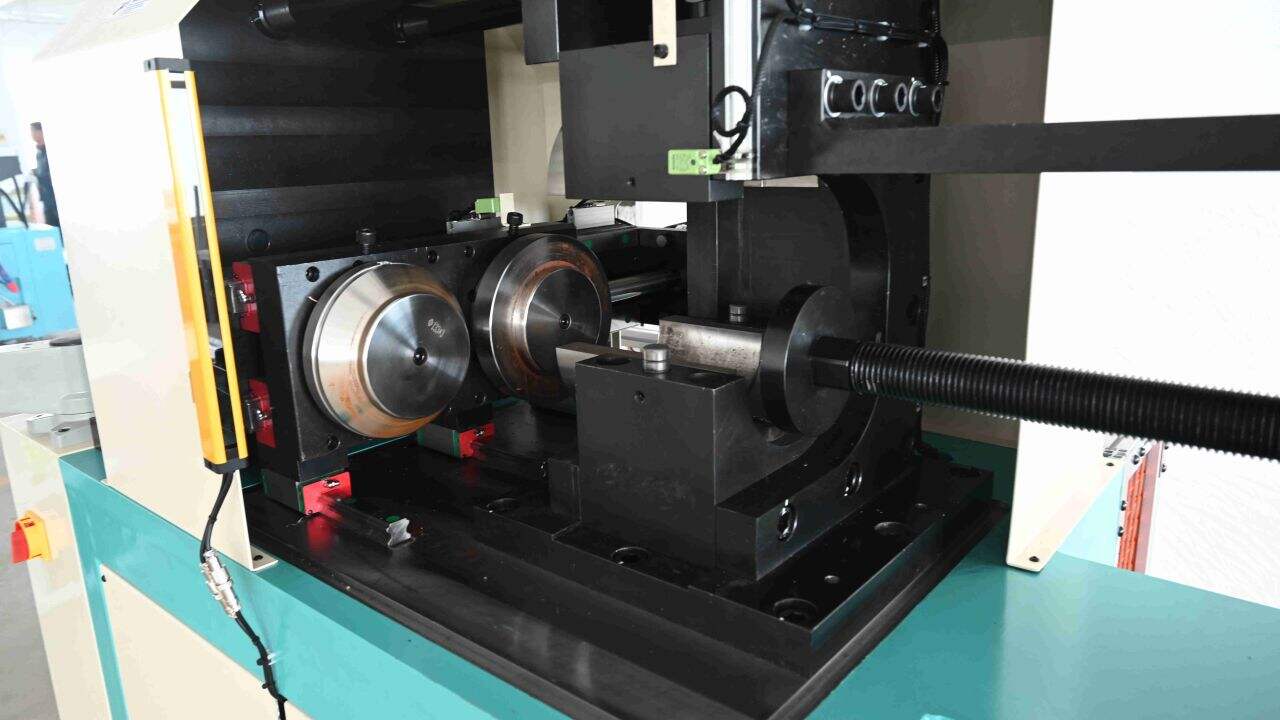

Autaatse nurgapuhastusmasinas on mõned peamised erilised osad, mis aitavad tal teha head tulemusi. Saate masina programmeerida või muuta sätteid, et teostada erinevaid tüüpe nurgapuhastust vastavalt oma toodete nõuetele. Nurgapuhastusmasinate tööriistad on erinevates kujuudes ja suurustes, mis muudab seadme kohandatavaks nõuetele vastavalt. Vedette autowoot nurklohistamise masin , näiteks, on lihtsaks kasutamiseks, et operaatorid saaksid süsteemi häälestada ilma põhjalikuma treeninguta.

Automaatne kaarekmuutuja kasutab äratähtsat ja edasijõudnud tehnoloogiat, et tagada sama tegevuse korrektne toimumine iga kord. See tehnoloogia aitab masina pakkuda täpsust ja ideaalset lõpufinishingut iga toote puhul, millega see rakendatakse. Automaatne kaarekmuutuja on disainitud nii, et tagada kõigi kaarekate servade võrdne kvaliteet, olles selle suurusest sõltumata. See konstantsus on tööstuses oluline ning seob klientide usalduse.

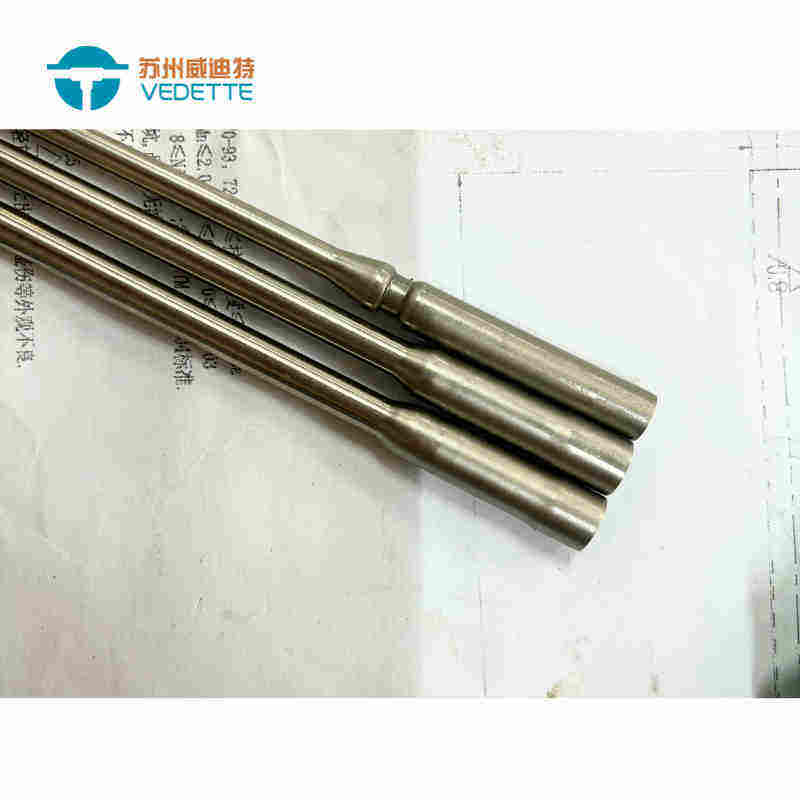

Automaatne kaarevõtmine masin võib suuresti aega ja raha säästa. Jah, see võib alguses veidi raha maksma, et masin osta, kuid see omakorda võib tegelikult aidata rohkem tooteid kiiremini teha ja hoida neid igakord erilises tasemel. Suurte Arvec tootjate puhul tähendaks see, et nende juures ei oleks vaja nii palju käsi tööks ja see kajastub otsestelt töökulusid madalamal tasandil. See Vedette tube kaarevuse loomise masin säästetud aeg ja raha võivad aidata sul keskenduda teistele tööintensiivsetele ülesannetele tehases või uutes projektides.

Suzhou Vedette Industrial Equipment Co., Ltd. algatas automaatse nurklooma masina tootmise 2011. aastal, asutades oma asukoha Suzhou lõunapoolse osa Taihu järve läheduses, mis on tootmisriistade innovatsioonikogukonna keskuses. Üle kümne aasta pika uurimis- ja arendus-, samuti tootmisnäolusega rörte töötlemise riistadega ning erinevate tüüpi kohandatud autoteeristega tootmisjoonidega, on ettevõte juhtiv riigi kõrgetehnoloogilise ettevõtteks, kes tegeleb kvaliteetsete, automaatsete ja edasipääsmiste riistade disainiga ja tootmiskeskkonnaga. Detsembris 2022 oli tal 31 kasuliku mudeli patendi ja 10 seadmete väljavaatepatenti. Seadmed leidis hea vastuvõtmise nii kodumaal kui ka välismaal, hinnates neid ülemaailmne klientide piirkond. Ettevõte on pühendunud oma ettevõtte eesmärgile kvaliteetsete toodete ja teenuste pakkmiseks, mis lisavad väärtust klientidele, ja on pühendunud olemaseks Hiinas rörte töötlemise riistade tehnoloogia edenemises esindajaks.

Suzhou VEDETTE, kui turul olev pipe töötlemise seadmete tootja automaatse nurga ümberkaevamise masina, pannakse suur tähtsus tehnoloogilise edenemisele ja uurimis- ja arendusinvesteeringutele ning konstantseks uute konkurentsivõimeline tootearendusega, et rahuldada muutuvaid turu nõudeid. Meie pühime endele elukvaliteedi ja klienti kogemuse eesmärgiks, pakudes sulle laia valikut professionaalseid teenuseid, sealhulgas enne-müügi toetust ja müügipärast tehnilist toetust, et tagada klientidele kiire ja tõhusa tehnilise abi ja lahendused. Meie tooted pakuvad laia rakendusalast, et rahuldada erinevate tööstusharude nõudeid pipe töötlemiseks. Kasutajatele, kes vajavad pipe töötlemise seadmesid, on Suzhou VEDETTE ideaalne valik.

Meie prioriteedina on alates alustusest automaatsete nürikeramite tootmisel kvaliteet. Selle tagamiseks jälgime pidevalt tootmeprotsesse, rakendame järk-järgult parandusi ning teeme kõik vajaliku, et tagada oma toodete kõrgeim kvaliteet ja selle konstantsus. Tulevikus jätkame samuti seda põhimõtet, samas kui püüame pidevalt parandada oma tooteid ja teenuseid, pakkudes nii klientidele suuremat väärtust.

Meie on teie automaatne kaarevõrgu masin laadimiseks rörkondade töötlemiseks, pakkudes mitmeid seadmeid, mis rahuldavad teie vajadusi. Me oleme tegelenud rörkondade töötlemise autotegevuses üle 10 aasta ja suudame pakkuda üle 1000 mittestandardse disainipilti. Pärast kliendi vajaduste põhjalikku mõistmist pakub kogemata müügiteenistus kohandatud teenuseid. Projektide plaanijate protsess järgneb meie seadmete tootmisele ja silumisele. Seadmete kokkupanekute ja silumiste protsessi saab klient vaadata igal hetkel võrgus. Kui seade läbib klienti poolt, siis nad tehakse väljumisjuhised täielikult vastavalt väljumisjuhise protsessile, et tagada seadmete kiire integreerimine klienti tootmisse. Meil on terviklik lugu seadmetest ja andmetest. Kliendi seadmete info säilitatakse nii dokumentides kui ka paberil. Mustrite uuendamine on viis joonestuste või kohandamise pakkmiseks. Pärast-müügi toetus pakub meie spetsialistite tiim.