Har du nogensinde overvejet, hvordan metalrør (i en stol eller på legepladsen, endda i cyklere) får huller i dem? Det er en god spørgsmål! Tubeperforeringmaskiner er emnet vi vil udforske i dag; drukn i verden af dem, få indsigt i, hvordan de fungerer for at forenkle og accelerere både virksomheders produktionsprocesser med Pressestempelsmaskine fra Vedette.

Manuelt håndtering af hål i rør foregår meget langsomt. Desuden kan de ikke altid være på samme sted hver gang, hvilket kan føre til større problemer senere. Derfor har vi avancerede rørhullmaskiner som kobberør pressemaskine fra Vedette. Det var maskiner, der havde til formål at udføre det samme arbejde, men hurtigere, nemmere og mere konsekvent.

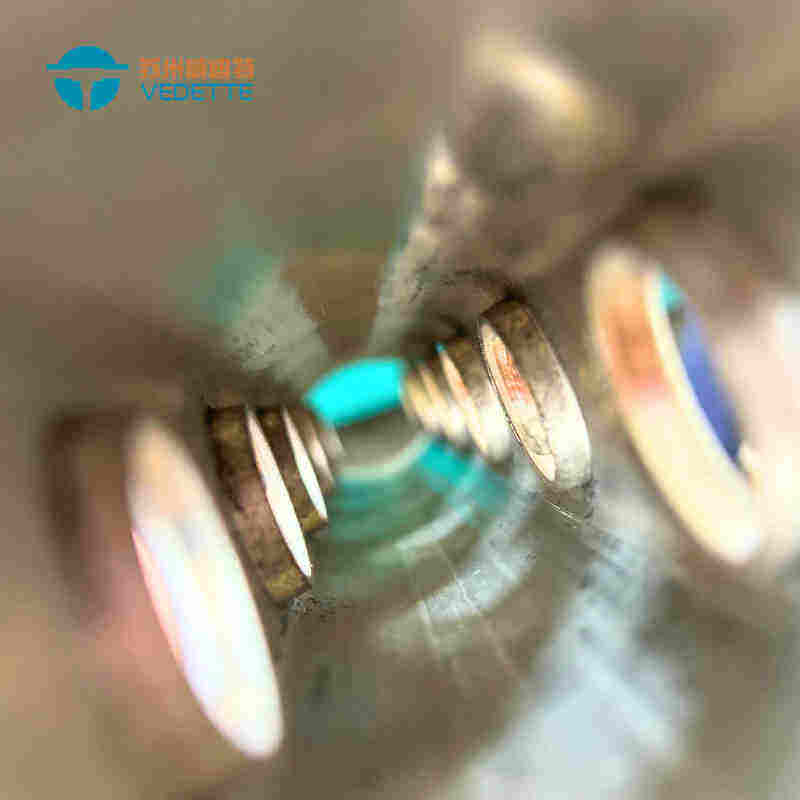

De nyeste rørpunchmaskiner har mange ekstra funktioner som kan gøre dit arbejde endnu bedre hver dag. Nogle maskiner kan for eksempel hjælpe dig med at justere dine rør og stansere flere rør ad gangen. Det vil spare dig endnu mere tid! Desuden kan disse maskiner ændre hvor hurtigt og hvor hårdt de slår afhængigt af hvilken type metal man bruger. Derfor kan man arbejde med metaller uden problemer ved hjælp af enkeltakset pressemaskine vedette. Nogle maskiner kan også have værktøjer, der kan måle og markere hvor hullerne skal gå. Dette vil hjælpe dig meget, især hvis du har brug for at skabe unikke designs til brugerdefinerede job.

Rørpunksmaskiner kan også anvendes til at fremstille mange forskellige produkter. Disse maskiner er som Rostfrit stål rør pressemaskine de kan punche forskellige former og størrelser, så du behøver ikke at købe mange forskellige maskiner til hver af dem. Det er meget mere praktisk for virksomhederne, fordi det hjælper dem med at være mere fleksible, når det kommer til at producere mange forskellige produkter.

De kan inkluderes i større produktionslinjer eller fungere på egen hånd som et separat, selvstændigt arbejdscenter. Hvis du integrerer dem i din nuværende arbejdsgang, kan du aflevere flere opgaver og producere hurtigere / flere varer. På denne måde kan din virksomhed skala op og åbne for muligheder at tage mere projekter uden at ansætte flere ressourcer, så vælg Flertydigheds pressemaskine .

Suzhou VEDETTE, som en fremtrædende producent af rørbehandlingsudstyr på markedet, lægger stor vægt på teknologisk udvikling samt forskning og udvikling, og fortsætter med at lancere nye produkter med markedskonkurrenceevne for at opfylde de altid skiftende krav fra markedet. Vi sætter kvaliteten og kundetilfredshed højt på dagsordenen og tilbyder en række højekvalitets-services, herunder forsalgsrådgivning, salgsteknisk support, efterforsyningsvedligeholdelse og sikrer, at kunder har adgang til professionel og tidlig teknisk hjælp og løsninger. Vores produkter kan anvendes i flere industrier. For brugere, der har behov for rørbehandlingsudstyr, er Suzhou VEDETTE helt sikkert den mest pålidelige valgmulighed.

Suzhou Vedette Industrial Equipment Co., Ltd., etableret i 2011, ligger nær Taihu-søen, en innovationshub inden for udstyrsproduktion. Det er et teknologisk avanceret nationalt firma med mere end 10 års erfaring inden for forskning, udvikling, produktion og tilpasning af automatiske produktionslinjer. I december 2022 havde det 31 nyttighedsmodeller og 10 opfindelsespatenter på udstyr. Udstyret er populært både hjemme og udadtil, med kunder fra hele verden. Firmaet holder sig til sin mission om at levere værdifulde produkter og tjenester til sine kunder og er engageret i at være en førende aktør i udviklingen af teknologiske innovationer inden for rørbehandling i Kina.

Vores virksomhed har i mere end 10 år produceret udstyr til automatisering af rørledningsbearbejdning, og vi har over 1000 design, der ikke er almindelige. Erfarne salgsprojekter vil tilpasse services baseret på en grundig forståelse af kundernes behov. Vores udstyr er designet og testet i overensstemmelse med projektets designproces. Kunder kan følge udstyrets montagetransport- og fejlsøgningsproces online når som helst. Når udstyret er godkendt, vil de gennemføre kontrollen ved afgang i overensstemmelse med leveringsprocessen for at sikre, at udstyret hurtigt kan integreres i kundens fabriksproduktionsprocesser. Vi har et perfekt system til opbevaring af data og udstyr. Alle papirfiler og elektroniske filer om rørtrillerudstyr og kunder bevares. Skabelonopdateringstjenesten kan bruges til at tegne skitser eller tilpassninger. Efter-salgshjælp ydes af vores hold af eksperter.

For at sikre stabilitet og kvalitet i vores Tube-punktering udstyr, holder vi fast ved princippet om kvalitet først og gennemfører andre foranstaltninger såsom kontrol af kilden samt overvågning af produktionen og kontinuerlig forbedring. I fremtiden vil vi fortsat holde fast ved princippet om kvalitet først. Vi vil fortsætte med at forbedre kvaliteten af vores produkter og tjenester for at skabe større værdi for vores kunder.