En punch-in-maskine er en enhed, der specifikt har til formål at hjælpe virksomheder med at overvåge de faktiske timer, deres medarbejdere bruger på arbejde. Denne Vedette Stansemaskine er en maskine, hvorigennem arbejdere logger deres tid ind og ud ved hjælp af et tidskort eller ved at indtaste deres oplysninger i en app eller elektronisk enhed. Chefen kan vide, hvornår arbejderne kom på arbejde, og hvornår de holder pause, hjemme igen. En stansemaskine gør medarbejdernes tidsregnskaber mere nøjagtige for virksomheder.

At drive en virksomhed ved, at løn kan være et helvede at finde ud af. Sammenlægning af arbejdstimer, hvilket kan være en lang proces, hvis det gøres manuelt for at finde ud af, hvor meget hver medarbejder vil få betalt. Denne proces af Vedette Stanse- og trækmaskine kan være meget arbejde og indimellem endda forvirrende, især hvis der er mange medarbejdere at styre. Heldigvis vil en punch-in-maskine have dig på vej tilbage til projektplanlægning hurtigt.

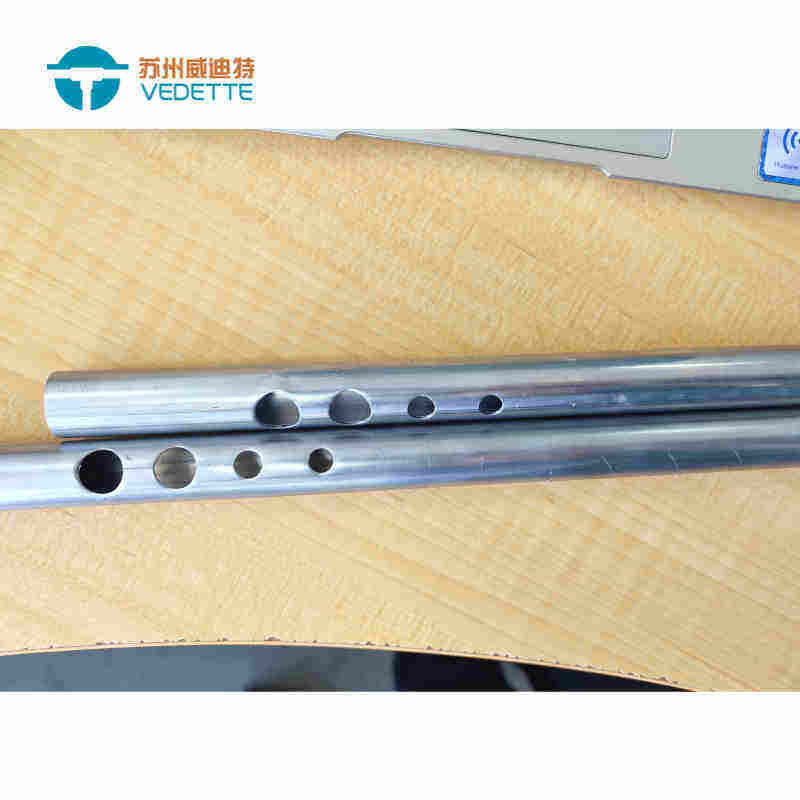

Du kan nemt registrere de timer, dine medarbejdere bruger, når du bruger en punch-in-maskine. Denne Vedette stansemaskine til kobberrør giver dig mulighed for at beregne lønsum korrekt og sikre, at alle bliver betalt, hvad de skylder i det rigtige beløb på det rigtige tidspunkt, så ingen bliver overbetalt eller undervurderet. I de fleste tilfælde kan maskiner nemt slå ind og har også software, der er gearet til at lave overtidsberegninger for dig samt spore feriedage og helligdage. Det betyder mindre hovedpine med hensyn til løn og mere tid til at investere i at vokse din virksomhed.

Punch in maskiner har revolutioneret den måde, virksomheder nu holder tid på deres ansatte. Det plejede at være papirtidskort eller logfiler, som virksomhederne holdt op med arbejdstimerne. Ulempen ved denne fremgangsmåde er ikke meget nyttig, og der opstod mange fejl. Men med fremkomsten af punch-in-maskiner kan arbejdsgivere nu spore timer, der arbejdes i et meget mere omhyggeligt og hurtigere tempo. Det hjælper virksomheder med at køre mere effektivt.

Ud over dette kan punchens rolle i maskiner ikke bagatelliseres, når det kommer til at sikre, at arbejdslovgivningen følges af virksomheder. Sporing af medarbejdertimer hjælper virksomheder med at forblive i overensstemmelse med standarderne for minimumsløn og overtidsbetaling. Dette vil gøre det muligt at undgå sådanne problemer som retssager og bøder, som er dyre i den mest bogstavelige betydning af dette ord.

Suzhou Vedette Industrial Equipment Co., Ltd. blev grundlagt i 2011 og er beliggende ved den smukke Taihu-sø i den sydvestlige del af Suzhou og er et vigtigt center for teknologisk innovation inden for produktion af udstyr. Det er en national virksomhed af topkvalitet, der har over 10 års erfaring med forskning, udvikling, fremstilling og ændring af automationsproduktionslinjer. Fra Punch in machine var den indehaver af 31 brugsmodeller og 10 patenter på opfindelser af udstyr. Dets udstyr er højt anset både i Kina og i udlandet, med mange kunder.

Suzhou VEDETTE, som en førende Punch-in-maskineproducent på markedet, lægger størst vægt på teknologisk innovation og investering i forskning og udvikling, og fortsætter med at lancere nye produkter, der konkurrerer om at opfylde markedets stadig mere diversificerede krav. Vi overholder livskvalitet, kundetilfredshed som det primære mål og leverer alle de professionelle tjenester, der dækker rådgivning inden for salg, salgsteknisk support, eftersalgsservice og sikring af, at kunderne får fordelen af rettidig og professionel teknisk assistance og løsninger . Vores produkter kan anvendes til en række forskellige industrier. Suzhou VEDETTE, som er en stor producent af rørbehandlingsudstyr, er det bedst egnede valg for dem, der skal bruge det.

Vi er din Punch-in-maskine til udstyr til at behandle rør, der tilbyder en bred vifte af udstyr til at opfylde dine behov. Vi har arbejdet med automationsudstyr til rørbearbejdning i over 10 år og er i stand til at tilbyde mere end 1000 ikke-standardiserede designmønstre. Efter en grundig forståelse af kundens behov vil det erfarne salgspersonale skræddersy ydelser. Planlægningsprocessen for projekter følges for at fremstille og fejlfinde vores udstyr. Processen med montering og fejlretning kan ses online af kunden til enhver tid. Efter at udstyret er accepteret af kunden, vil de udføre en udgangsinspektion i fuldstændig overensstemmelse med udgangsleveringsproceduren for at sikre, at udstyret hurtigt integreres i kundens fabriksproduktionsprocesser. Vi har en fejlfri registrering af udstyr og data. Oplysningerne om kundens udstyr bevares både i dokumenter og på papir. Formopdatering er en måde at levere tegninger eller tilpasning på. Eftersalgssupport ydes af vores ekspertteam.

For at sikre konsistens og fremragende produktkvalitet For at sikre kvalitet og stabilitet i vores produkter, følger vi først præmissen om kvalitet og tager derefter yderligere foranstaltninger såsom kontrol af kilden, der kontrollerer produktionsprocessen samt løbende forbedringer. Vi vil blive ved med at overholde kvalitets-først-princippet i fremtiden og forbedre vores produkter og tjenester for at levere Punch in-maskine til vores kunder.