আপনি কখনো চিন্তা করেছেন কি ভাবে ধাতব টিউব (চেয়ারে, খেলাঘরে, বা সাইকেলে) এর মধ্যে ছিদ্র তৈরি হয়? এটি একটি ভাল প্রশ্ন! আজ আমরা টিউব পাঞ্চিং মেশিনের দিকে তাকাবো; এই বিষয়ে নিবিষ্ট হন, এবং জানুন কিভাবে এগুলি কাজ করে ব্যবসাদের পণ্য তৈরির প্রক্রিয়াকে সহজ এবং দ্রুত করে। প্যান্সিং মেশিন ভেডেট থেকে।

টিউব হাতে পাঞ্চিং করা একইভাবে ধীর গতিতে সম্পন্ন হয়। এছাড়াও, তারা প্রতি বার একই জায়গায় না থাকলেও এটি ভবিষ্যতে বড় সমস্যা তৈরি করতে পারে। এই কারণেই আমরা উন্নত টিউব পাঞ্চিং যন্ত্র ব্যবহার করি যেমন ক্যাপার পাইপ পাঞ্চিং মেশিন ভেডেট থেকে। তারা একই কাজ করার উদ্দেশ্যে যুক্ত ছিল কিন্তু তারা তাড়াতাড়ি, সহজ এবং সঙ্গত ছিল।

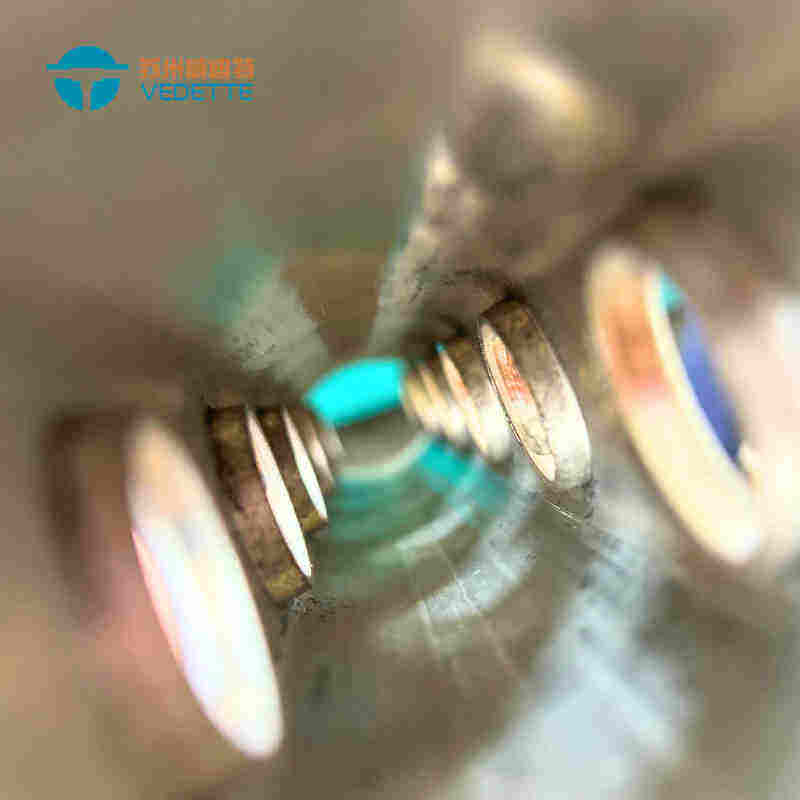

সবচেয়ে নতুন টিউব পাঞ্চিং মেশিনগুলি অনেক অতিরিক্ত বৈশিষ্ট্য রয়েছে যা আপনার কাজকে প্রতিদিন আরও ভালো করতে পারে। উদাহরণস্বরূপ, কিছু মেশিন আপনাকে আপনার টিউব সমান করতে এবং একসাথে একাধিক টিউব পাঞ্চ করতে সহায়তা করতে পারে। এটি আপনার আরও বেশি সময় বাঁচাবে! এছাড়াও, এই মেশিনগুলি আপনার ব্যবহার করা মেটালের ধরনের উপর নির্ভর করে কতটা দ্রুত এবং শক্তভাবে পাঞ্চ করতে পারে। সুতরাং, আপনি কোনো সমস্যার সাথেই মেটাল ব্যবহার করতে পারেন যদি একক-অক্ষ পাঞ্চিং মেশিন ভেডেট থেকে। কিছু মেশিনে যন্ত্রপাতি সহ থাকতে পারে যা বুঝাতে এবং চিহ্নিত করতে পারে যেখানে গর্ত থাকবে। এটি আপনাকে খুব সাহায্য করবে, বিশেষ করে যদি আপনাকে কাস্টম কাজের জন্য বিশেষ ডিজাইন তৈরি করতে হয়।

টিউব পাঞ্চিং মেশিনগুলি ব্যবহার করে অনেক বিভিন্ন পণ্য তৈরি করা যেতে পারে। এই মেশিনগুলির মধ্যে যেমন স্টেনলেস স্টিল পাইপ ছেদন যন্ত্র বিভিন্ন আকৃতি এবং আকার পাঞ্চ করতে পারে, তাই আপনাকে প্রতিটির জন্য অনেক বিভিন্ন মেশিন কিনতে হবে না। এটি ব্যবসার জন্য অনেক বেশি সুবিধাজনক কারণ এটি অনেক বিভিন্ন পণ্য উৎপাদনের সময় আরও লম্বা হতে সাহায্য করে।

এগুলি বড় উৎপাদন লাইনের অংশ হিসেবে অন্তর্ভুক্ত করা যেতে পারে অথবা একটি আলাদা, স্বতন্ত্র কাজের কেন্দ্র হিসেবেও কাজ করতে পারে। যদি আপনি এগুলি আপনার বর্তমান কাজের ফ্লোয় যুক্ত করেন, তাহলে আরও বেশি কাজ শেষ করতে পারবেন এবং দ্রুত বা আরও বেশি জিনিস উৎপাদন করতে পারবেন। এভাবে আপনার ব্যবসা বৃদ্ধি পেতে পারে এবং আরও অনেক প্রকল্পে কাজ করার সুযোগ পাবেন বাড়িয়ে না তুলে আরও সম্পদ নিযুক্ত করার প্রয়োজন ছাড়াই, তাই এটি বাছাই করুন। বহু-গর্ত ছেদন যন্ত্র .

সুচৌ ভেডেট, বাজারে পাইপ প্রসেসিং মেশিনের একজন প্রধান উৎপাদনকারী হিসেবে, প্রযুক্তি উন্নয়ন এবং গবেষণা ও উন্নয়নের বিনিয়োগের উপর গুরুত্ব দেয় এবং বাজারের প্রতিযোগিতামূলক নতুন পণ্য চালু করতে থাকে যা বাজারের অবিরাম পরিবর্তনশীল প্রয়োজনের সাথে মিলে। আমরা উচ্চ গুণবাদ এবং গ্রাহকদের সন্তুষ্টি আমাদের প্রধান উদ্দেশ্য হিসেবে রেখেছি এবং বিক্রির আগের পরামর্শ, বিক্রির সময় তথ্য সমর্থন, এবং বিক্রির পরের রক্ষণাবেক্ষণ সহ একটি বিস্তৃত উচ্চ গুণের সেবা প্রদান করি যা গ্রাহকদের পেশাদার এবং সময়মত তথ্য সমর্থন এবং সমাধানের প্রয়োজন নিশ্চিত করে। আমাদের পণ্যগুলি বিভিন্ন শিল্পে ব্যবহার করা যেতে পারে। যারা পাইপ প্রসেসিং মেশিনের প্রয়োজন রয়েছে, তারা জন্য সুচৌ ভেডেট নিশ্চয়ই সবচেয়ে বিশ্বস্ত বিকল্প।

সুচৌ ভেডেট ইন্ডাস্ট্রিয়াল ইকোয়িপমেন্ট কো., লিমিটেড, ২০১১ সালে প্রতিষ্ঠিত, তাইহু হ্রদের কাছে অবস্থিত, যেখানে উৎসাহিত করা হয় একটি বিশেষ কেন্দ্রে যন্ত্রপাতি নির্মাণ খন্ডে। এটি একটি প্রযুক্তি আधুনিক জাতীয় কোম্পানি যা গবেষণা, উন্নয়ন, নির্মাণ এবং স্বয়ংশাসিত অটোমেশন প্রোডাকশন লাইন তৈরি করতে বেশ ১০ বছরেরও বেশি অভিজ্ঞতা রয়েছে। ২০২২ সালের ডিসেম্বরে, এটি ৩১ ব্যবহারিক মডেল এবং ১০টি উপকরণ সম্পর্কে আবেদন করেছে। এই উপকরণগুলি ঘরে এবং বিদেশেই জনপ্রিয়, এবং বিশ্বব্যাপী গ্রাহকদের কাছ থেকে প্রাপ্ত। কোম্পানি তাদের গ্রাহকদের জন্য মূল্যবান উপকরণ এবং সেবা প্রদানের মিশনে বাধ্য এবং চীনে টিউব প্রসেসিং উপকরণের প্রযুক্তি উন্নয়নের নেতৃত্বে আগ্রহী।

আমাদের কোম্পানি ১০ বছরের অধিক সময় ধরে পাইপলাইন প্রসেসিং অটোমেশন সরঞ্জাম তৈরি করছে এবং আমাদের কাছে ১০০০ টিরও বেশি ডিজাইন রয়েছে যা সাধারণ নয়। অভিজ্ঞ বিক্রয় প্রজেক্টগুলি গ্রাহকদের প্রয়োজনের উপর ভিত্তি করে সেবা পরিবর্তন করবে। আমাদের সরঞ্জাম প্রজেক্ট ডিজাইন প্রক্রিয়া অনুযায়ী ডিজাইন ও পরীক্ষা করা হয়। গ্রাহকরা যেকোনো সময় সরঞ্জামের আসেম্বলি এবং ডিবাগিং প্রক্রিয়া অনলাইনে ফলো করতে পারেন। সরঞ্জামটি অনুমোদিত হলে, তারা ব্যবহার পরিবর্তনের প্রক্রিয়া অনুযায়ী বাহিরের পরীক্ষা করবে যেন সরঞ্জামটি গ্রাহকের কারখানার উৎপাদন প্রক্রিয়ায় দ্রুত একীভূত হয়। আমাদের কাছে ডেটা এবং সরঞ্জামের জন্য একটি অক্ষত স্টোরেজ সিস্টেম রয়েছে। সর্বশেষ সরঞ্জাম সম্পর্কিত সমস্ত টিউব পাঞ্চিং সরঞ্জাম এবং গ্রাহকদের কাগজের ফাইল এবং ইলেকট্রনিক ফাইলে সংরক্ষিত রয়েছে। মল্ড আপডেট সার্ভিসটি স্কেচ অঙ্কন বা স্বার্থের জন্য ব্যবহৃত হতে পারে। পরবর্তী বিক্রয় সহায়তা আমাদের বিশেষজ্ঞ দল দ্বারা প্রদান করা হয়।

আমাদের পণ্যের টিউব পাঞ্চিং যন্ত্রের স্থিতি এবং গুণগত মান নিশ্চিত করতে আমরা মান প্রথম ধারণার অনুসরণ করি এবং উৎসের নিয়ন্ত্রণ এবং উৎপাদন প্রক্রিয়া পরিবেশন এবং সतতা উন্নয়ন ইত্যাদি অন্যান্য উপায় বাস্তবায়ন করি। ভবিষ্যতে আমরা মান প্রথম ধারণার অনুসরণ করতেই থাকব। আমরা আমাদের পণ্য এবং সেবার মান বাড়াতে থাকব যাতে গ্রাহকদের জন্য বড় মূল্য তৈরি করা যায়।