Ви коли-небудь спостерігали, як хтось згинає трубу, щоб зробити щось на кшталт рами велосипеда чи дворового паркану чи навіть вихлопної труби вашого автомобіля? Це захоплююче дивитися! Ці трубки мають бути точно зігнуті, щоб правильно ковзати в кожне відповідне місце. Саме тут на допомогу приходить гідравлічний трубогиб. Це спеціальний інструмент, який може точно та зручно згинати ці труби, щоб забезпечити їх ідеальну посадку

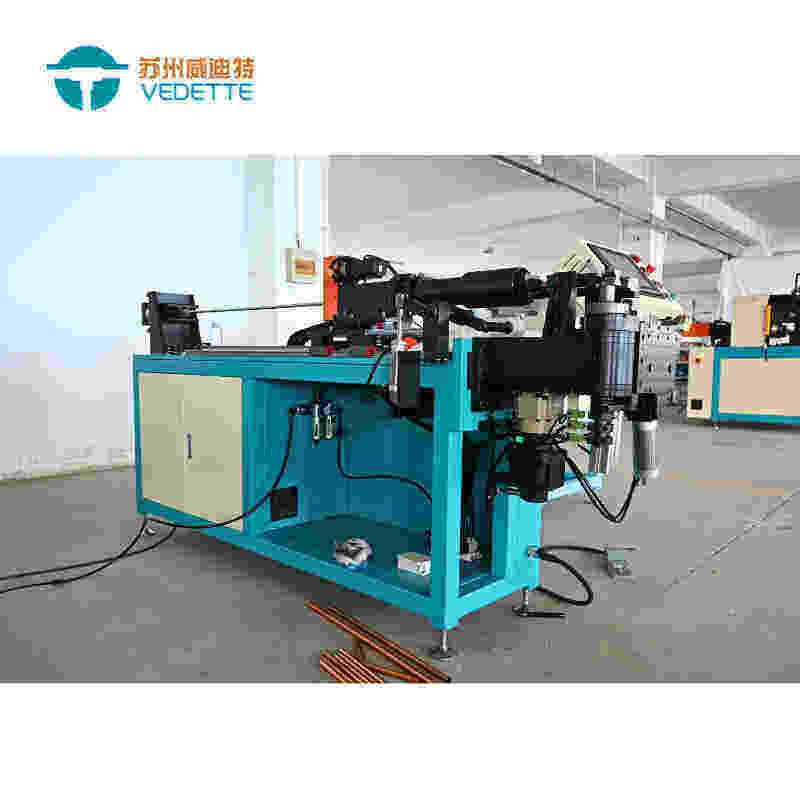

Як працює гідравлічний трубогиб? Мені дуже подобається ця техніка, оскільки вона згинає труби, не перегинаючи їх і не викликаючи будь-якої деформації. Це дозволяє уникнути фізичного навантаження, для роботи великих камерних трубогибів потрібні люди! Ватерлінію можна швидко та легко згинати, інакше це було б кошмаром з ручними згинальними машинами, оскільки ви могли б легко створити вм’ятини або нерівні вигини. Але а Верстат для згинання труб Vedette забезпечує точні, повторювані результати. Тобто кожен куточок виглядає добре і відчувається так, як і має бути.

Гідравлічний трубогиб дозволяє легко виготовляти складні форми та конструкції. У деяких галузях промисловості, де виробництво продукції вимагає згинання труб, це може бути безцінним навиком. За допомогою гідравлічного трубогиба можна виконати широкий спектр згинів, таких як криві, кути та U-форми, тому дизайнеру більше не потрібно робити це менш складним

Ці згини включають додатковий набір інструментів, які називаються плашками. Друкований дизайн відрізняється для кожної матриці, і його можна замінити відповідно до уподобань клієнта. Це дозволяє адаптувати гідравлічний трубогиб для різних завдань обробки. З цієї причини гідравлічні трубогиби необхідні в таких галузях, як виробництво автомобілів, літакобудування та будівництво мостів, де надзвичайно важливо досягти точного згинання.

Зберігання гідравлічної технології дозволяє мати якісні та ефективні рішення згинання труб. Перша Ведетта Різальна машина економить час Вимагає менше праці І друге Результат завжди хороший! У гідравлічних трубогибах присутній величезний поршень з достатнім тиском, щоб згинати трубу, не завдаючи шкоди. Це дозволяє оператору набирати тиск, необхідний для конкретного вигину.

Це не тільки робить роботу швидшою та легшою, але й забезпечує кращі вигини з більш плавними радіусами. Найбільш типовими моделями гідравлічного трубозгинального верстата є ті, які використовують тиск рідини для формування відповідного згину. Він захоплює трубку, яка потім згинається навколо неї, тому не рухається. Останнє дає ще чіткішу та гарнішу лінію згину, завдяки чому кінцева частина виглядатиме набагато краще.

Завдяки цим розширеним функціям інструмент може виготовляти труби однакового розміру та форми, що має спростити збірку на наступному етапі. Наприклад, це робить Vedette Продукти добре працюють і усувають проблеми, оскільки комплекти вставок регулюються для гарної орієнтації, що забезпечує покращений комфорт під час їх носіння, причому постійність є ключем до всього цього. Чим точніше виготовлення продукту, тим вищий рівень довіри та задоволення у покупців.

Гідравлічний трубогиб, як провідний виробник обладнання для обробки труб у галузі, надає великого значення технологічним інноваціям та інвестиціям у дослідження та розробки та продовжує впроваджувати нові продукти, конкурентоспроможні на ринку, щоб задовольнити мінливі потреби ринку. Ми прагнемо надати вам експертні послуги, включаючи передпродажні консультації та технічну підтримку з продажу та післяпродажну підтримку. Це гарантує, що клієнти отримають оперативні та надійні рішення. Наші продукти широко застосовуються в різних галузях промисловості. Якщо ви користувач, якому потрібне обладнання для обробки труб, Suzhou VEDETTE — надійний найкращий вибір.

Гідравлічний трубогиб завжди буде підтримувати якість нашої продукції як основу, гарантуючи, що ми контролюємо моніторинг виробничого процесу джерела, постійне вдосконалення контролю джерела, серед іншого, щоб гарантувати високу якість і довговічність продукту. Ми продовжуватимемо дотримуватись цього принципу в майбутньому та продовжуватимемо вдосконалювати наші продукти та послуги, щоб надавати більшу цінність клієнтам.

Suzhou Vedette Industrial Equipment Co., Ltd., заснована в 2011 році, розташована на південному заході Сучжоу в безпосередній близькості від озера Тайху, інноваційного центру в секторі виробництва обладнання. Це високотехнологічна національна компанія з більш ніж десятирічним досвідом у дослідженнях, розробках, виробництві та налаштуванні автоматизованих виробничих ліній. На момент запуску в грудні 2022 року він був власником 31 корисної моделі та 10 патентів на винаходи обладнання. Обладнання, яке воно виробляє, є високоякісним гідравлічним трубогибом як у Китаї, так і в усьому світі з численними клієнтами.

Наша компанія виробляє обладнання для автоматизації обробки трубопроводів більше 10 років, і ми маємо понад 1000 нетипових конструкцій. Досвідчені проекти продажів налаштують послуги на основі глибокого розуміння потреб клієнтів. Наше обладнання розроблено та перевірено відповідно до процесу розробки проекту. Клієнти можуть у будь-який час спостерігати за процесом складання та налагодження обладнання онлайн. Коли обладнання буде схвалено, вони проведуть перевірку виходу відповідно до процесу виходу, щоб переконатися, що обладнання можна швидко інтегрувати у заводські виробничі процеси замовника. У нас бездоганна система зберігання даних і обладнання. Уся інформація про гідравлічний трубогиб про обладнання та клієнтів зберігається в паперових та електронних файлах. Службу оновлення прес-форми можна використовувати для малювання ескізів або на замовлення. Післяпродажне обслуговування надає наша команда експертів.