Een punchmachine is een apparaat dat specifiek is ontworpen om bedrijven te helpen bij het bijhouden van de werkelijke uren die hun werknemers besteden aan werk. Deze Vedette Ponsmachine is een machine waarmee werknemers hun tijd aankloppen en afkloppen met behulp van een tijdskaart of door hun gegevens in te voeren in een app of elektronisch apparaat. De baas kan zien wanneer de werknemers zijn begonnen en wanneer ze pauze nemen of naar huis gaan. Een klopapparaat maakt tijdbesteding door medewerkers nauwkeuriger voor bedrijven.

Als je een bedrijf runt, weet je dat het uitrekenen van loonstrookjes een hel kan zijn. Het optellen van gewerkte uren, wat een lang proces kan zijn als het handmatig wordt gedaan om uit te vogelen hoeveel elke werknemer betaald zal krijgen. Dit proces van Vedette Perforatie- en trekmachine kan veel werk zijn en af en toe zelfs verwarrend, vooral als er veel medewerkers moeten worden beheerd. Gelukkig zorgt een in- en uitslagapparaat ervoor dat je snel terug bent bij het plannen van projecten.

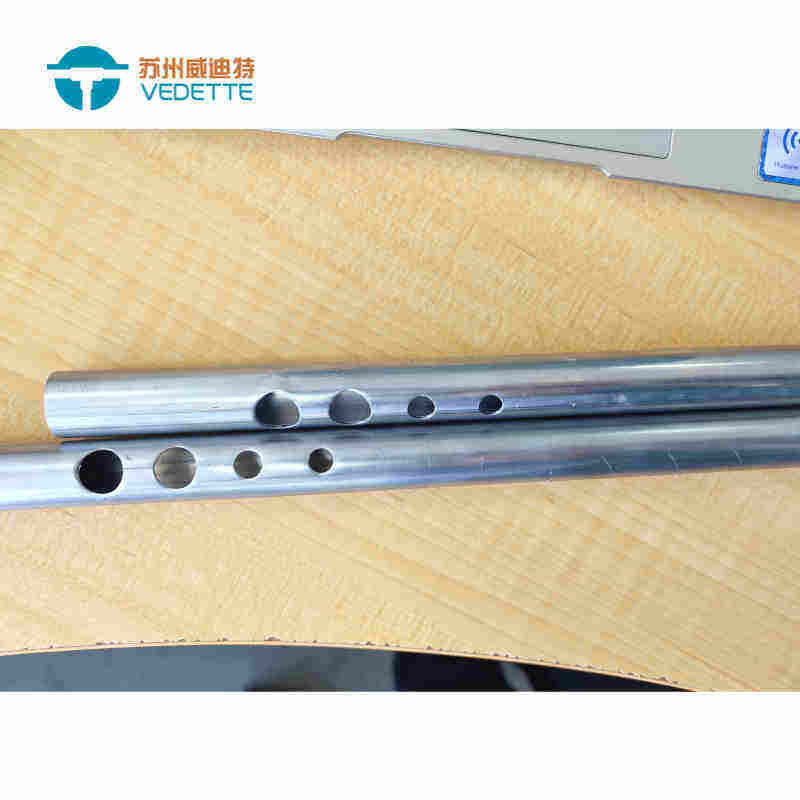

Je kunt eenvoudig de uren registreren die door je werknemers zijn doorgebracht wanneer je een in- en uitslagapparaat gebruikt. Deze Vedette koperbuis perforatiemachine laat je toe om loonstrookjes correct te berekenen en ervoor te zorgen dat iedereen betaald wordt met het juiste bedrag op de juiste tijd, zodat niemand overbetaald of onderschat wordt. In de meeste gevallen hebben moderne in- en uitslagmachines ook software die overuren voor je berekent en vakantiedagen en feestdagen bijhoudt. Dit betekent minder hoofdpijn over loonadministratie en meer tijd om je bedrijf te laten groeien.

De inkomst van punchmachines heeft de manier waarop bedrijven de werktijd van hun medewerkers bijhouden ingrijpend veranderd. Vroeger werden papieren tijdkaarten of logboeken gebruikt om de werkuren bij te houden. Het nadeel van deze methode is dat het niet erg nuttig was en er veel fouten voorkwamen. Maar met de komst van punchmachines kunnen werkgevers nu de uren die gewerkt zijn op een veel zorgvuldiger en snellere manier bijhouden. Het helpt bedrijven efficiënter te opereren.

Daarnaast kan de rol van punchmachines niet worden onderschat wanneer het gaat om het naleven van arbeidsregels door bedrijven. Het bijhouden van de uren van medewerkers helpt bedrijven om in overeenstemming te blijven met de minimumloon- en overwerkvergoedingnormen. Dit maakt het mogelijk om problemen zoals rechtszaken en boetes, die financieel gezien duur zijn, te voorkomen.

Suzhou Vedette Industrial Equipment Co., Ltd. is opgericht in 2011 en ligt bij de prachtige Taihu-meer in het zuidwesten van Suzhou en is een belangrijk centrum voor technologische innovatie in de productie van apparatuur. Het is een vooraanstaand nationaal bedrijf dat meer dan 10 jaar ervaring heeft in onderzoek, ontwikkeling, fabricage en aanpassing van automatische productielijnen. In termen van Punch-machines is het de eigenaar van 31 nuttige modellen en 10 apparatenpatenten. De apparatuur wordt zowel binnen als buiten China hoog gewaardeerd, met veel klanten.

Suzhou VEDETTE, als een vooraanstaande fabrikant van Punch in machine op de markt, hecht de hoogste prioriteit aan technologische innovatie en investeringen in onderzoek en ontwikkeling, en blijft nieuwe producten lanceren die voldoen aan de steeds diversere eisen van de markt. We houden ons aan de kwaliteit van leven en hebben klanttevredenheid als primair doel, terwijl we al het professionele serviceaanbod bieden, inclusief voorverkoopadvies, verkoopstechnische ondersteuning, nasale service, en ervoor zorgen dat klanten profiteren van adequaat en professioneel technisch assistentie en oplossingen. Onze producten kunnen worden toegepast in verschillende industrieën. Suzhou VEDETTE, een belangrijke fabrikant van buisbewerkingsapparatuur, is de meest geschikte keuze voor hen die het nodig hebben om te gebruiken.

Wij zijn uw Punch-in machine voor uitrusting om buizen te verwerken en bieden een verscheidenheid aan apparatuur om uw behoeften te vervullen. We hebben al meer dan 10 jaar gewerkt in het veld van automatiseringsapparatuur voor buisverwerking en kunnen meer dan 1000 niet-standaard ontwerpmodellen aanbieden. Na een grondige analyse van de klantbehoeften biedt het ervaren verkoop personeel maatwerk diensten. Het projectplanningproces wordt gevolgd door de productie en debugging van onze apparatuur. Het montage- en debugproces kan door de klant op elk moment online worden gevolgd. Nadat de apparatuur is goedgekeurd door de klant, wordt er een uitkomstcontrole volgens het leveringsproces uitgevoerd om ervoor te zorgen dat de apparatuur snel wordt geïntegreerd in de productieprocessen van de fabriek van de klant. We hebben een perfecte registratie van apparatuur en data. De informatie over de klantapparatuur wordt zowel in documenten als op papier bewaard. Mold-updating is een manier om tekeningen of Customization te verstrekken. Nasale ondersteuning wordt verleend door ons team van experts.

Om consistentie en uitmuntendheid in productkwaliteit te waarborgen, volgen we het principe van kwaliteit eerst en nemen daarnaast extra maatregelen zoals controle van de bron, controle van het productieproces en continue verbetering. In de toekomst blijven we ons richten op het principe van kwaliteit voorop en zullen we onze producten en diensten verbeteren om de Punch-in-machine aan onze klanten te leveren.