ლითონის ჭრა, ალბათ, ერთ-ერთი ყველაზე რთული და მოთხოვნადი პროცესია, რაც კი ოდესმე განხორციელებულა. მისი მამა ასევე მუსიკოსი იყო, მაგრამ ჩემი შვილი მასზე უკრავს ისეთ დონეზე, რომელსაც მე მიმაჩნია, რომ ძალიან დაძაბულია და მოითხოვს ძალასა და უნარს. ხალხს ასე ხშირად უჭირს ლითონის ნაჭერთან შეხვედრის გამოცდილება და მისი ხელით მოჭრა რაღაცით, რაც მეტი არაფერია: ძირითადი ხელსაწყო. ამან შეიძლება გამოიწვიოს შეცდომები და ზოგჯერ უბედურებაც! ახლა ამ თანამედროვე სამყაროში ყველაფერი შემდეგი თაობის Vedette საჭრელი მანქანის წყალობით. სამუშაო უფრო ადვილი და ზუსტი გახდა იმ მუშაკებისთვის, რომლებიც აკეთებენ ან საქმე აქვთ მასალების ჭრას. აღსანიშნავია, რომ ამ მანქანებს შეუძლიათ ლითონების დაჭრა ნებისმიერი სასურველი ზომისა და ფორმის დიდი სიზუსტით. თითოეული ეს პუნქტი განმარტავს ვედეტის სხვადასხვა უპირატესობებს საჭრელი მანქანა და როგორ ცვლიან წარმოების მიდგომას ქარხნებისა და სახელოსნოების ფარგლებში.

რეალურ არსში, CNC საჭრელი მანქანა შეიძლება ჩაითვალოს ერთგვარ სუპერ ხელსაწყოად, რომელიც ეფექტურად ახორციელებს მაღალ ზუსტ და პროფესიონალურ ჭრას ლითონის ფურცლებზე და სხვა მასალებზე. რომ შევაჯამოთ, წარმოების პროცესში მრავალი სახის ამ მანქანების გამოყენებას მრავალი უპირატესობა აქვს. პირველი ის არის, რომ ის იცავს მუშებს, რადგან მათ არ აქვთ უფლება გამოიყენონ ხელი, მაგალითად, ბასრი პირები. ეს მუშებს უფრო კომფორტულს ხდის და შეუძლიათ თავიანთი სამუშაოს ეფექტურად შესრულება. გარდა ამისა, ისინი მართლაც სწრაფია და ასევე ძალიან კარგად იჭრება, რაც გრძელვადიან პერსპექტივაში ზოგავს დროს. სიჩქარე: ეს სიჩქარე მწარმოებლებს საშუალებას აძლევს უფრო სწრაფად მიაწოდონ თავიანთი პროდუქცია. დაბოლოს, პროდუქტის ხარისხის გაუმჯობესების ასპექტში, CNC საჭრელი მანქანები იყენებენ კარგად აწყობილ და მუდმივ სიზუსტეს, რათა შეამცირონ პირების დაბინძურება ადამიანის შეცდომებისგან. ეს მხარს უჭერს საბოლოო პროდუქტის ხარისხის/ეფექტურობის გაუმჯობესებას, რაც საკმაოდ აუცილებელია ბიზნეს სამყაროში.

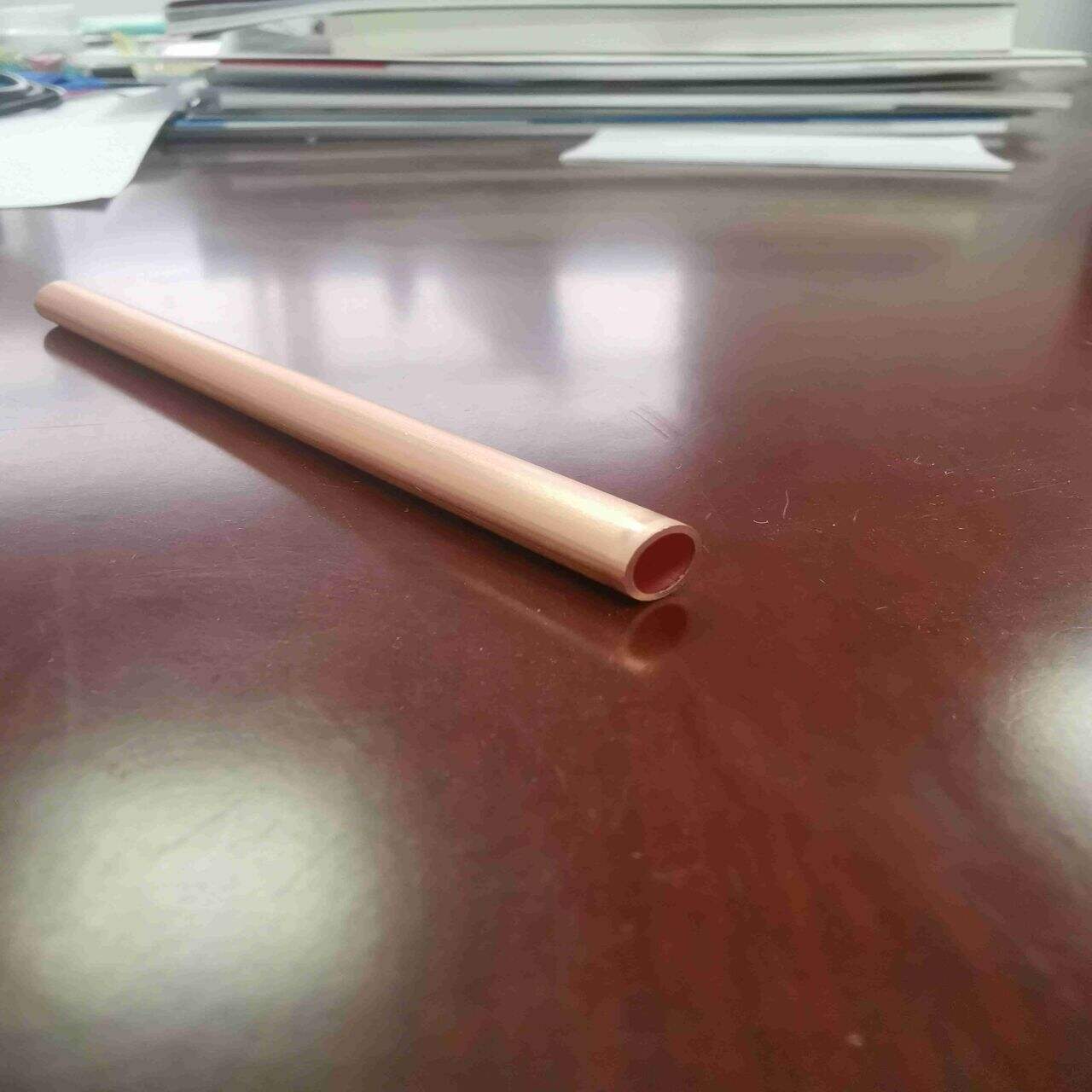

თქვენ წარმოების პროცესში შეძლებთ ჭრის ავტომატურად გაკეთებას, რადგან ეს არის Vedette CNC საჭრელი დანადგარები პერსონალიზაციის გამო. ასეთი ავტომატიზაცია სავარაუდოდ შეამცირებს ხარჯებს და დროს საჭირო პროდუქტების გასაუმჯობესებლად და ამავე დროს გააუმჯობესებს იგივეს. ვედეტი ერთი/ორმაგი მილი ჩიპიანი საჭრელი მანქანა შეიძლება იყოს ხელსაწყო, რომელსაც მწარმოებლები იყენებენ იმ მასალისთვის ფორმებისა და დიზაინის მისაცემად, რაც ხელნაკეთის შემთხვევაში, საჭირო იქნება ადამიანის ექსპერტი. ამ გზით მათ შეუძლიათ შეასრულონ თავიანთი სამუშაო უფრო სწრაფად და მესამე არის შრომის ხარჯების უფრო დიდი ხარისხით მიმართვა. ამ მანქანებით, იმდენი რამ არის, რისი გაკეთებაც ბიზნესს შეუძლია თავისი დროის უმეტესი ნაწილი ახალი პროდუქტების დიზაინისა და ინოვაციისთვის, ვიდრე მათი ხელით მოჭრა.

CNC საჭრელმა მანქანებმა მართლაც გარდაქმნა და განსაზღვრა ლითონის დამუშავების ინდუსტრია. 3D ბეჭდვის კონცეფციის მიხედვით, ეს მანქანები მწარმოებლებს საშუალებას აძლევს მიიღონ მართლაც შეკვეთილი ლითონის ნაწილი უმოკლეს დროში - სწორად და ზუსტად შესრულებული. ამ ახალ ტექნოლოგიას შეუძლია მრავალი კომპონენტის დამზადება უფრო სწრაფი ტემპით მომხმარებელთა მოთხოვნების დასაკმაყოფილებლად. ეს ეხმარება მომხმარებელს მიაღწიოს უკეთ შეკვეთილ ელექტრონულ კომერციას, რათა სხვა ორგანიზაციებმა შეძლონ ზარალის დათრგუნვა ეფექტური ოპერაციების მეშვეობით. მან ნამდვილად უნდა მოახდინოს რევოლუცია მწარმოებლების მუშაობის გზაზე, რათა დარწმუნდეს, რომ ყველაფერი ნაკლებად რთული და, შესაბამისად, უფრო გამოსაყენებელია.

Vedette CNC საჭრელი მანქანები ყოველთვის აერთიანებს უახლეს ტექნოლოგიას, რათა უზრუნველყოს ზუსტი და ტექნიკურად სწორი ჭრა, რომელიც აკმაყოფილებს მომხმარებლის მოთხოვნებს ლითონის ფურცლებზე ან სხვა მასალებზე. ეს არის კომპიუტერების გამოყენება ჭრის პროცესის დასახმარებლად, რაც ზრდის მის სიზუსტეს. უპირატესობები, რასაც CNC ტექნოლოგია მისცემს, იქნება უკეთესი დასრულება, უფრო სწრაფი პროდუქტიულობა და უფრო იაფი გრძელვადიან პერსპექტივაში. ეს საშუალებას აძლევს მწარმოებლებს წარმოადგინონ უნიკალური პროდუქტები, რომლებიც პირდაპირ აკმაყოფილებენ მომხმარებელთა საჭიროებებს. ის ასევე ხდის სამუშაო ადგილებს უსაფრთხოს; ადამიანები, რომლებიც უშუალოდ აღარ არიან საქმე ბასრ დანებთან, ამცირებენ ტრავმის მიღების შანსს.

წარმოების ინდუსტრიაში, ერთი ახალი რამ, რაც ბაზარზე გამოჩნდა, არის CNC საჭრელი მანქანები. ეს არის ჭრების ავტომატიზაციის პროცესი, რაც იწვევს არა მხოლოდ უფრო სწრაფ, არამედ ზუსტი. ეს გაფართოება საშუალებას აძლევს კომპანიებს გამოაქვეყნონ უკეთესი პროდუქტები, რაც საბოლოოდ გაზრდის მომგებიანობას. ვედეტი სწორი მილის საჭრელი მანქანა მწარმოებლებს საშუალებას აძლევს აწარმოონ ლითონის კონსტრუქციები ხელით ჭრის საჭიროების გარეშე. ეს ნიშნავს, რომ ისინი ხელმისაწვდომია უფრო დიდი პროექტებისთვის და შეიძლება უფრო რეაგირებენ მომხმარებელთა შეკითხვებზე.

Cnc საჭრელი მანქანა უზრუნველყოფს ჩვენი პროდუქციის უმაღლეს ხარისხს და სტაბილურობას. ჩვენ ვიცავთ პირველ რიგში ხარისხის პრინციპს, ისევე როგორც სხვა ნაბიჯებს, როგორიცაა წყაროს კონტროლი, ასევე წარმოების პროცესის მონიტორინგი და მუდმივი გაუმჯობესება. მომავალში ჩვენ გავაგრძელებთ ხარისხის პრინციპის დაცვას. ჩვენ გავაგრძელებთ პროდუქტებისა და სერვისების დონის გაუმჯობესებას, რათა მეტი ღირებულება მივიღოთ ჩვენი მომხმარებლებისთვის.

Suzhou VEDETTE არის მილების დამუშავების მოწყობილობების წამყვანი მწარმოებელი ინდუსტრიაში. იგი დიდ აქცენტს აკეთებს Cnc საჭრელ მანქანაზე, კვლევასა და განვითარებაზე და გამოუშვა ახალი პროდუქტები, რომლებიც კონკურენტუნარიანია ბაზრის მუდმივად ცვალებადი მოთხოვნების დასაკმაყოფილებლად. ჩვენ მზად ვართ მოგაწოდოთ საექსპერტო მომსახურება, რომელიც მოიცავს წინასწარი გაყიდვების კონსულტაციას და გაყიდვების ტექნიკურ მხარდაჭერას და გაყიდვების შემდგომ მომსახურებას. ეს უზრუნველყოფს, რომ კლიენტებმა მიიღონ სწრაფი და ეფექტური გადაწყვეტილებები. ჩვენი პროდუქცია შეიძლება გამოყენებულ იქნას ინდუსტრიების ფართო სპექტრში. მომხმარებლებისთვის, რომლებსაც სჭირდებათ აღჭურვილობა მილების დამუშავებისთვის, Suzhou VEDETTE უდავოდ ყველაზე საიმედო არჩევანია.

Suzhou Vedette Industrial Equipment Co., Ltd., დაარსებული 2011 წელს, მდებარეობს სუჟოუს სამხრეთ-დასავლეთით, Cnc საჭრელი მანქანის მახლობლად, ინოვაციური ცენტრი Cnc საჭრელი მანქანის წარმოებაში. ეს არის მაღალტექნოლოგიური კომპანია, რომელსაც აქვს 10 წელზე მეტი გამოცდილება კვლევის შემუშავებაში, ავტომატიზაციის საწარმოო ხაზების წარმოებასა და შეცვლაში. 2022 წლის დეკემბერში გაშვების დროს მას ჰქონდა 31 სასარგებლო მოდელი და 10 გამოგონების პატენტი, რომლებიც დაკავშირებულია აღჭურვილობასთან. მისი აღჭურვილობა კარგად არის მიღებული ეროვნულ და საერთაშორისო დონეზე, კლიენტებთან მთელ მსოფლიოში. კომპანია ემორჩილება თავის ძირითად მისიას - მიაწოდოს მაღალი ხარისხის პროდუქტები და მომსახურება მომხმარებლებისთვის და მზად არის იყოს ლიდერი მილების დამუშავების აღჭურვილობის ტექნოლოგიური წინსვლის სფეროში ჩინეთში.

ჩვენ ვართ მილების დამუშავების აღჭურვილობის ერთჯერადი მიმწოდებელი, რომელიც გთავაზობთ აღჭურვილობის მთელ რიგს თქვენი საჭიროებების დასაკმაყოფილებლად. ჩვენ ორიენტირებული ვართ მილების დამუშავების ავტომატიზაციის აღჭურვილობის სფეროში 10 წელზე მეტი ხნის განმავლობაში და შეგვიძლია შემოგთავაზოთ 1,000-ზე მეტი არასტანდარტული დიზაინის სქემა. გაყიდვების გამოცდილი პროექტები მოახდენს სერვისების მორგებას მომხმარებელთა მოთხოვნების საფუძვლიანი ანალიზის შემდეგ. ჩვენი აღჭურვილობა იწარმოება და ვითარდება Cnc საჭრელი მანქანის მიხედვით. აწყობისა და გამართვის პროცესის ნახვა მომხმარებელს ონლაინ ნებისმიერ დროს შეუძლია. აღჭურვილობის მიღების შემდეგ ისინი ჩაატარებენ გასასვლელ ინსპექტირებას გასასვლელის მიწოდების პროცესის შესაბამისად, რათა მოწყობილობა სწრაფად იყოს ინტეგრირებული მომხმარებლის ქარხნული წარმოების ამოცანებში. ჩვენ გვაქვს მონაცემთა და აღჭურვილობის სისტემის არქივის სისტემა, რომელიც სრულიად საიმედოა. მომხმარებლის ყველა აღჭურვილობის ინფორმაცია ინახება ქაღალდის ფაილებში და ელექტრონულ ფაილებში. ყალიბის განახლებამ შეიძლება უზრუნველყოს ილუსტრაციები ან პერსონალიზაცია. გაყიდვების შემდგომ მომსახურებას ჩვენი პროფესიონალი გუნდი უზრუნველყოფს.