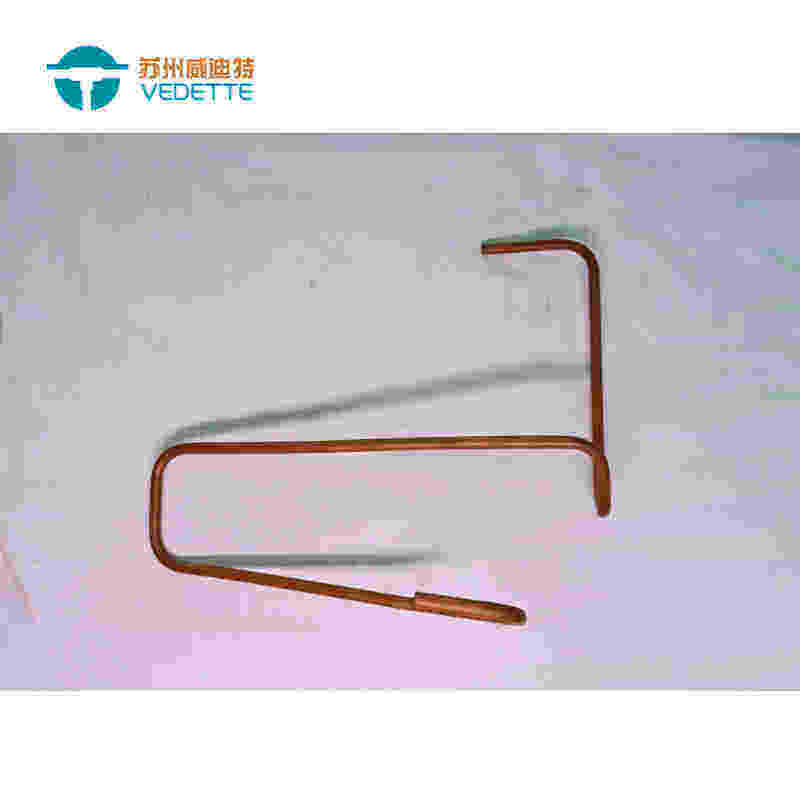

Ბევრი მაशინები მუშაობს ფაბრიკებში და წარმოების საფабრიკო ქარიშნებში, რათა პროდუქტები შეიქმნას უფრო სწრაფად. ეს მაშინების შორის, ავტომატური ტუბის გამრუდების მაშინა ძალიან მნიშვნელოვანია. ეს ერთადერთი მაშინა განკუთვნილია ისე, რომ ვედეტი სპილის მაღაზის ხვრელის მანქანა შეიძლება გამრუდოს ტუბები ნებისმიერი სიგრძის, ტიპისა და დიამეტრის მიხედვით მათ ნატურალური რადიუსით ყველაზე მარტივად. ეს დახმარება ფაბრიკებს უფრო სწრაფად მუშაობაში და უფრო მეტი რამ წარმოებაში ნაკლები დროში.

Ავტომატურ საბრძანებელი მაशინის გამოყენებით დაკავშირებული არის რამდენიმე წარმოშობა. Vedette ერთი ღერძის ხვრელის მანქანა ჯერ ყოველთვის დაზოგვს დროს. საბრძანებელის აღჭარბებისა და ჩამოჭარბების პროცესი საბაზოდ განმეორებს შემდეგ ტექნიკურ ნაბიჯებს, რომლებიც ხდება კომპიუტერ-კონტროლირებული საბრძანებელი მაშინებით, ყოველი ავტომობილური გამოსვლის სისტემისთვის გამოყენებული ყოველი სიმაღლისთვის: ეს ნიშნავს, რომ ფაბრიკები შეძლებენ მეტ რაოდენობის საბრძანებლის წარმოება ნაკლები დროის განმავლობაში. ასევე, ფული დაზოგება იმის განსაზღვრავით, რომ თქვენ გადაირიცხავთ მაშინის მომსახურებას, რადგან მსგავსი მაშინები შეძლებენ საათების განმავლობაში მუშაობას განახლების გარეშე. მაშინები მუშაობას შეძლებენ განახლების გარეშე, რაც არ არის ადამიანისთვის, რომელსაც საჭიროა განახლებები და გარეშე რეჟიმი, რაც ძალიან სასარგებლოა ბიზნესებისთვის.

Ავტომატური მილის დახრილი მანქანა ასევე შეიძლება დაზოგოს ბევრი შრომის ხარჯები. ტუმბოების დახრილობა შეიძლება მოხდეს მანქანით, რის შედეგადაც ამისთვის ნაკლები მუშაკი საჭიროა. ეს კომპანიებს საშუალებას აძლევს ნაკლები დახარჯონ მუშებზე, რომლებიც ხელოვნურად ასრულებენ დავალებებს, რომლებიც შეიძლება შედარებით განმეორებითი იყოს. ოჲ-ჱაეჲბნჲ, ვეეთ Მრავალ ღერძის ხვრელის მანქანა ძალიან სწრაფად ხდება და ამგვარად ხელს უწყობს კომპანიას, რომ გარკვეული დროის განმავლობაში უფრო მეტი პროდუქტი აწარმოოს. ეს ნიშნავს, რომ კომპანია იზოგავს შრომას და ზოგადად უფრო პროდუქტიულია, - განმარტა მან.

Ავტომატური მილის დახრის მანქანის სიმძლავრე და სიზუსტე ეს არის ძალიან ძლიერი მანქანები, რომლებსაც შეუძლიათ უზარმაზარი სიზუსტით შექმნან გლუვი დახრები მილსადენებში. ეს სიზუსტე კრიტიკულია ბევრი ბიზნესისთვის სადაც მათი პროდუქტები ყოველთვის ერთნაირი უნდა იყოს. ხელმისაწვდომობა სხვადასხვა ზომის სხვადასხვა ტიპის მილები შესაძლებელია გამო უპირატესი სიძლიერე, რომელიც ეს მანქანა სთავაზობს და შედეგად, Ხვრელისა და გადატანის მანქანა გახდეს მრავალფუნქციონალური იнструმენტი წარმოებლებისთვის, რომლებიც განკუთვნილია რამდენიმე წარმოების პროცესისთვის.

Თუ თქვენ ასევე გეგონიათ ყიდვა ავტომატური ტუბის გამრუდების მაशინი თქვენს ფაბრიკაზე, მაშინ ამას არ უნდა გადახატოთ. Მრავალხური ჩაჭრვის მაშინა შეიძლება გამოიყენონ დროსა და ფულს შენახვისთვის, მაღალი მწარმოების მდგომარეობის მისაღებად, რაც ჩაი Gaussian განსხვავებული მასალების ტიპები და ტუბის დიამეტრები. არის გამოსადეგი ინსტრუმენტი, რომელიც შეიძლება გახდეს თქვენს ფაბრიკაში უფრო კერძოდ და განათლებული.

Ავტომატური ქვედარის გამრუდების მაशინა, როგორც წარმოებლის მეხსიერება მაღალი დონის ქვედარის მუშაობის მაशინების სფეროში, ძალიან მნიშვნელოვანი უფასოდ ჩათვლის ტექნოლოგიურ ინოვაციებს და კვლევით-განვითარების ინვესტიციებს და უწყვეტლად შეიტანს ახალ პროდუქტებს, რომლებიც მარკეტინგულ კონკურენტობას ჰქვია, რათა მორგებული ბაზარის ცვლილებების საჭიროების შესაბამისად მოხდეს. ჩვენ გვაქვს განსაკუთრებული მისიонი გთავაზობთ ექსპერტული სერვისები, მათ შორის წინასწარი კონსულტაციები და ტექნიკური მხარდაჭერა გაყიდვისას და შემდეგ მხარდაჭერა. ეს უზრუნველყოფს მომხმარებლების მიღებას სწრაფი და მართვის მოქმედი ამოხსნები. ჩვენი პროდუქტები ძალიან გავრცელებულია რამდენიმე ინდუსტრიაში. თუ თქვენ ხართ მომხმარებელი, რომელიც საჭიროა ქვედარის მუშაობის მაशინები, სუǒუნძის VEDETTE არის მოსასვლელი საუკეთესო არჩევანი.

Suzhou Vedette Industrial Equipment Co., Ltd., 2011 წელს დაფუძნებული, მდებარეობს სუჩოუში, ქალაქის სამხრეთ-დასავლეთ ნაწილში, ტაიჰუ ტბის ახლოს, რაც არის ინოვაციის ცენტრალური ადგილი აღჭურვილი ეკიპმენტის წარმოების სექტორში. ეს არის საერთაშორისო ტექნოლოგიური კომპანია, რომელიც მეტი ვითარებს ათი წლის განმავლობაში ავტომატური წარმოების ხაზების კვლევაში, განვითარებაში, წარმოებაში და პერსონალიზებაში. დეკემბერში 2022, მას მოიყვა ავტომატური მაგიდის გამრგვალების მაशინის საშინაო მოდელი და 10 ინვენციული პატენტი ეკიპმენტის შესახებ. ისინი წარმოებული ეკიპმენტი მაღალი სასურველია ჩინეთში და მსოფლიოს სხვადასხვა ქვეყანაში, რაც მიიღო ბევრი მომხმარებელი.

Ავტომატური მილის დახრილი მანქანა კომპანია მწარმოებს მილის დამუშავების ავტომატიზაციის აღჭურვილობას 10 წელზე მეტი ხნის განმავლობაში და ჩვენ გვაქვს 1000-ზე მეტი დიზაინი, რომელიც არ არის ტრადიციული. მას შემდეგ, რაც ჩვენ გვაქვს სრული გაგება ჩვენი კლიენტების მოთხოვნები და მოთხოვნები, ჩვენი გამოცდილი გაყიდვების გუნდი შეუძლია მორგებული მომსახურება თქვენი საჭიროებების. პროექტით დაგეგმვის პროცესი მოჰყვება ჩვენი აღჭურვილობის წარმოებას და დებუგს. მომხმარებელს შეუძლია ნებისმიერ დროს უყუროს მოწყობილობის დამზადებას და დებუგინგის პროგრესს ონლაინ. მას შემდეგ, რაც მომხმარებელი მიიღებს აღჭურვილობას, ისინი ჩაატარებენ გასასვლელ ინსპექტირებას, სრული შესაბამისობით გასასვლელი მიწოდების პროცედურასთან, რათა უზრუნველყონ, რომ აღჭურვილობა დაუყოვნებლივ ჩაერთოს მომხმარებლის ქარხნულ წარმოების ამოცანებში; ჩვენ მომხმარებლის მოწყობილობა ინახება როგორც ელექტრონულ, ასევე ქაღალდურ ფაილებში. ფორმის განახლება შეიძლება უზრუნველყოს ილუსტრაციები ან პერსონალიზაცია. გაყიდვების შემდგომ მხარდაჭერა უზრუნველყოფილია ჩვენი გამოცდილი გუნდის მიერ.

Ჩვენ ყოველთვის ავტომატური ტუბის გამრუდების მაशინის გარკვეული ხარისხით როგორც ძირითადი მიზანი, დარწმუნებით რომ კონტროლირებთ წყაროს მონიტორингს პროდუქციის პროცესებში, უნარეს გაუმჯობესება და სხვა ზომები გარკვეული ხარისხის უმაღლესი დონეზე და ხარისხის ერთობლივობის გარანტირებისთვის. ჩვენ განადებით მივაჩნიათ ამ პრინციპს მომავალ წლებში და განადებით გაუმჯობესებას ჩვენი პროდუქტები და სერვისები, რომ უფრო მეტი მნიშვნელოვანი მნიშვნელობა გთავაზოთ ჩვენს მომხმარებლებს.