Dobrý den, mladý čtenáři! Dnes se tedy naučíme něco opravdu důležitého, a sice koncové tvarování trubek! Trubky pro tvarování konců lze také definovat jako proces, kdy se tvar konce kovové trubky mění tak, aby se vešla do jiné trubky. cnc ohýbání trubek nebo část. Může se to zdát jednoduché, ale ve skutečnosti to vyžaduje pořádné vybavení a motorizované pomůcky. Vedette je společnost, která ví docela dost o koncových tvářecích trubkách a my se s vámi podělíme, proč využít naši pomoc, když potřebujete tento typ práce.

Velmi se zaměřujeme na každou malou nuanci toho, jak vyrábíme naše kovové trubky. Když trubka přirozeně nemá správný tvar na svém konci, může být obtížné zapadnout do jiné části sestavy nebo se s ní spojit. Ty mohou být nebezpečné pro všechny zúčastněné. Je to něco jako snažit se nacpat dva dílky skládačky, které do sebe nezapadají, a nazvat to shodou. Používáme jen to nejlepší stroj na řezání kovových trubek a techniky ve Vedette, které zajišťují, že naše trubky jsou vyráběny s láskou a kvalitou. Každý produkt je přezkoumán naším týmem odborníků, aby se zjistilo, zda daný produkt splňuje vysoké standardy, které jsme stanovili. Naši zákazníci tedy mohou produktům důvěřovat, my jen chceme uvést maličkosti na pravou míru.

Použitím speciálních metod tváření konců podporujeme kovové trubky, aby fungovaly mnohem efektivněji a vykonávaly jejich funkce v úspěšné metodě. Vzplanutí — Rozevlátý konec trubky. To umožňuje kapalinám, jako je voda nebo plyn, procházet trubicí bez potíží. Můžete si to představit jako tobogán – šířka je to, kolik dětí může sjet dolů najednou! Vedette poskytuje několik typů aplikací koncového tváření, takže naši zákazníci si mohou vybrat, která z nich bude pro ně nejlepší na základě toho, co hledají. Můžeme to udělat, abychom jim pomohli dosáhnout lepších výsledků pro každý z jejich podniků.

Ve Vedette víme, že každý zákazník má jiné potřeby a přání. To je důvod, proč jsou naše procesy koncového tváření trubek přizpůsobeny požadavkům našich zákazníků. Materiál trubky, velikost a tvar trubky se mohou lišit. Každý má svou oblíbenou příchuť zmrzliny: stejně jako u projektů se může váš počet najetých kilometrů lišit. Stále máme stejný tým kdykoli po ruce, abychom zákazníkům poskytli návrhy na řešení dalších problémů! Uděláme vše pro to, abychom s našimi zákazníky mluvili tak, jak chtějí, abychom jim mohli vše ušít přesně tak, jak chtějí.

Můžeme zvýšit pevnost kovových trubek a prodloužit jejich životnost jednoduše použitím technik tvarování konců. Beading: Proces, který vytváří malý hrbolek na konci trubice To pomáhá zajistit, že trubice je zajištěna a zůstává na místě, aniž by osiřela nebo se rozdrtila. Je to stejně těžké jako snažit se držet kluzký míč. Ale některé úchopy to usnadňují. Kování je další postup zmenšování posledního průměru válce. Tím se vytvoří ohýbačka měděných trubek silnější a odolnější vůči zranění. Naše trubky mohou odolat a odolat při použití správných technik, i když stejně jako silný strom není silný za všech podmínek. Ve Vedette máme řadu technik tvarování konců, abychom zajistili, že naši zákazníci budou schopni optimalizovat své kovové trubky.

End forming tube byla založena v roce 2011 a nachází se v blízkosti nádherného jezera Taihu na jihozápadě Suzhou, centra technologických inovací ve výrobě zařízení. S více než desetiletými zkušenostmi ve vývoji, výzkumu a výrobě zařízení na zpracování trubek a různých druhů výrobních linek pro zakázkovou automatizaci, které jsou národní high-tech společností, která se zabývá vývojem a výrobou technologicky automatizovaných a inteligentních zařízení. Stejně jako v prosinci 2022 má 31 patentů na užitné vzory a 10 patentů na vynálezy zařízení. Zařízení je dobře přijímáno jak doma, tak v zahraničí, s klienty po celém světě. Společnost dodržuje svůj firemní cíl nabízet hodnotné produkty a služby pro své zákazníky a je odhodlána být lídrem v oblasti technologického pokroku pro zařízení na zpracování trubek v Číně.

Vždy jsme měli jako primární cíl vysokou kvalitu koncových trubek tím, že zajišťujeme kontrolu zdroje monitorování výrobních procesů, neustálé zlepšování a další opatření, abychom zajistili nejvyšší kvalitu a stálost kvality našich produktů. Tohoto principu se budeme držet i v blízké budoucnosti a budeme pokračovat ve zdokonalování našich produktů a služeb, abychom našim zákazníkům nabídli vyšší hodnotu.

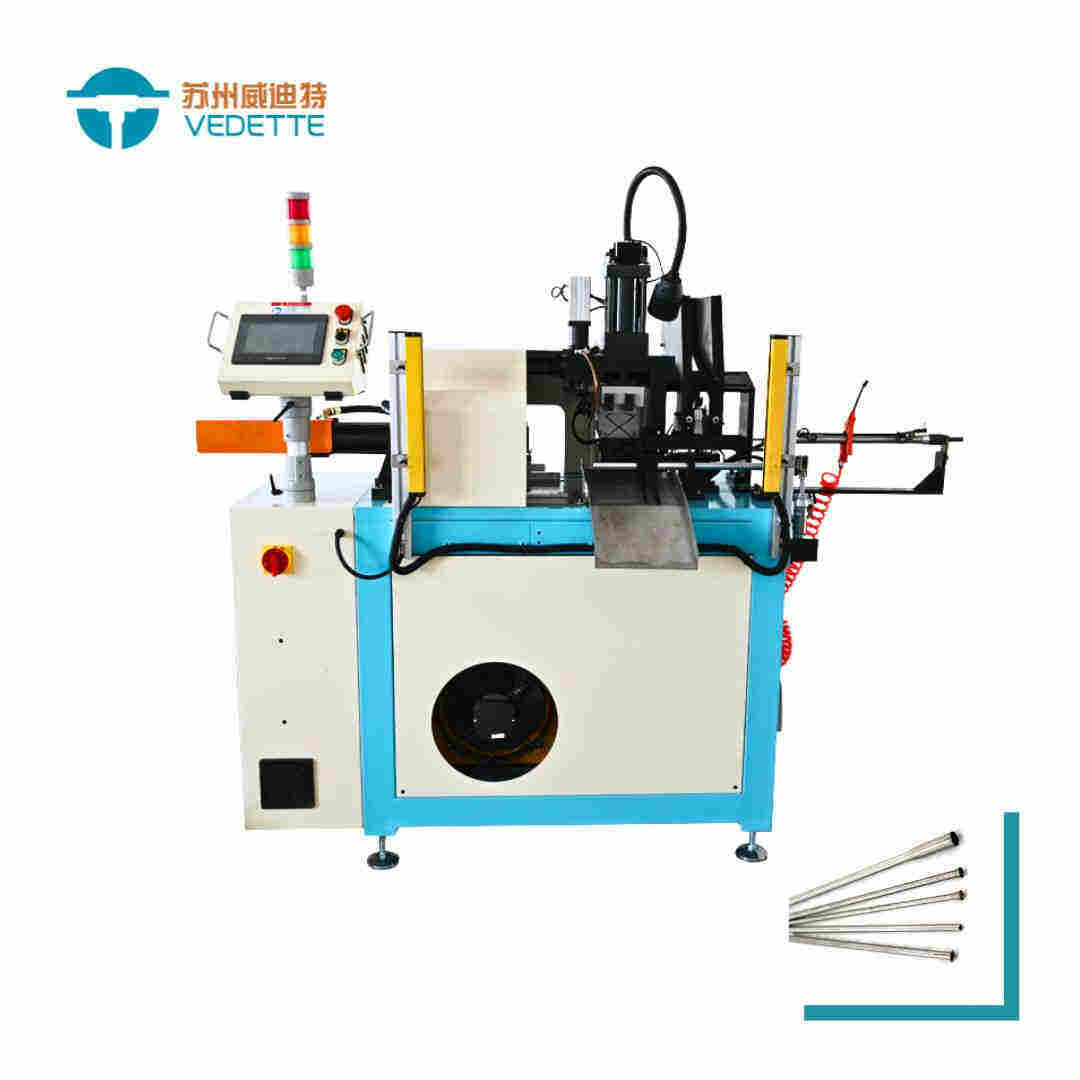

Jsme komplexním dodavatelem zařízení na zpracování trubek a poskytujeme řadu zařízení, které splní vaše potřeby. Již více než 10 let pracujeme v oblasti automatizačních zařízení pro zpracování potrubí a jsme schopni nabídnout více než 1,000 nestandardních konstrukčních konceptů. Odborně vyškolené prodejní týmy mohou přizpůsobit řešení na základě důkladného porozumění potřebám zákazníků. Naše zařízení vyrábíme a demontujeme podle projektového plánu. Zákazníci mohou kdykoli online sledovat proces montáže a ladění zařízení. Jakmile bude zařízení přijato, provedou výstupní inspekci po přísném výstupním postupu dodávky, aby bylo možné zařízení použít pro výrobu trubek pro koncové tváření v továrních výrobních úkolech klienta. Máme dokonalé vybavení a systém archivace dat. Informace o zařízení zákazníka jsou uloženy jak v dokumentech, tak v papíře. Službu aktualizace forem lze použít k vytvoření výkresů nebo přizpůsobení. Máme vysoce kvalifikovaný poprodejní tým, který zajišťuje poprodejní čištění a údržbu.

Suzhou VEDETTE, jako výrobce trubek pro koncové tváření trubek na trhu, klade nesmírný důraz na technologický pokrok a investice do výzkumu a vývoje a neustále uvádí na trh nové produkty s konkurenceschopností na trhu, aby splnily neustále se měnící požadavky trhu. Zavázali jsme se ke kvalitě života, zákaznické zkušenosti jako našemu hlavnímu cíli, poskytovat vám celou řadu profesionálních služeb včetně předprodejní podpory i prodejní technické podpory poprodejní podpory, abychom zajistili, že zákazníci budou mít přístup k rychlou a efektivní technickou pomoc a řešení. Naše produkty nabízejí široké uplatnění, aby splnily požadavky různých průmyslových odvětví při zpracování trubek. Pro uživatele, kteří potřebují zařízení na zpracování trubek, je Suzhou VEDETTE ideální volbou.