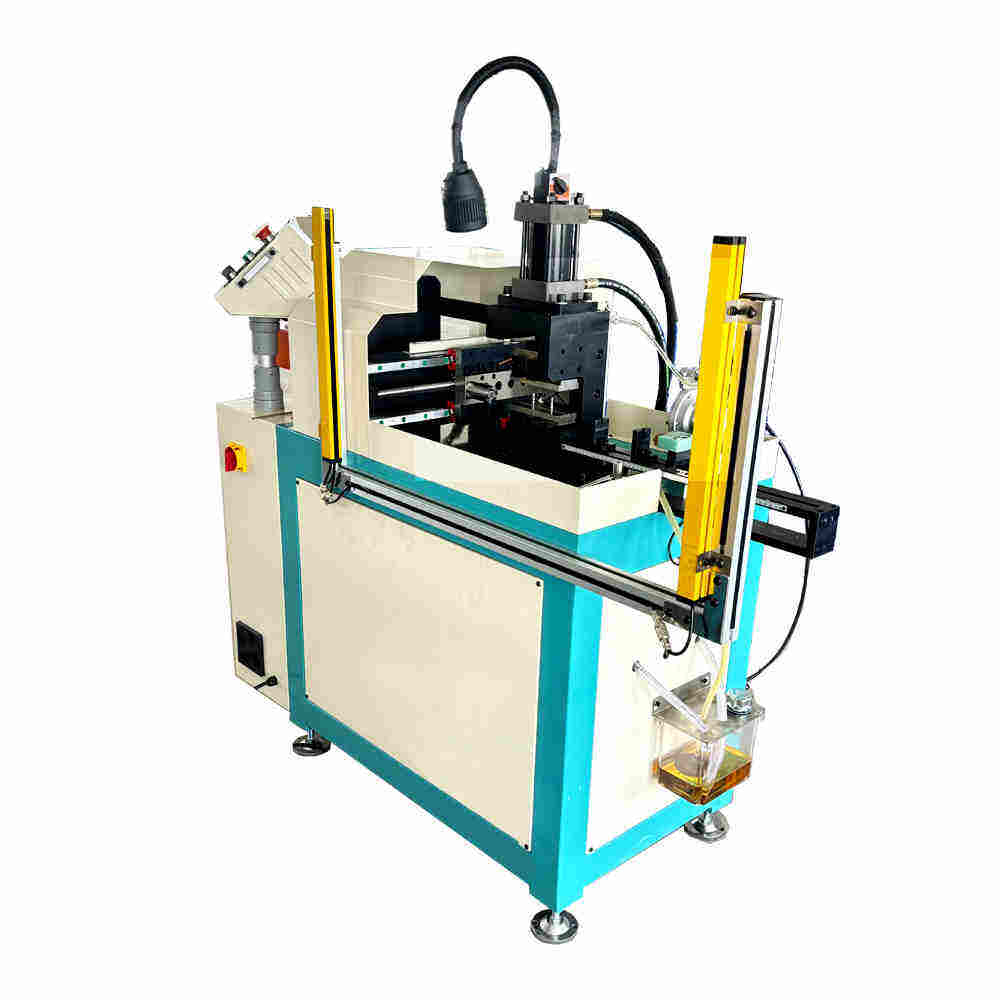

الألمنيوم هو معدن خفيف جدًا، ويمكن العثور عليه في العديد من المنتجات الشائعة مثل الطائرات والسيارات وعلب المشروبات الغازية! إنه مفيد جدًا لأنه قوي ولكن خفيف. عندما يتعلق الأمر بالأنابيب الألمنيومية، غالبًا ما يكون من الضروري تغييرها أو إعادة تشكيلها إلى شكل معين لتمكينها من أداء وظيفة معينة. هنا يأتي دور آلة أنابيب الألمنيوم فديت لتقديم المساعدة.

الآلة فديت، كما هي، فريدة للغاية لأنها قادرة على تغيير طرفي الأنابيب الألمنيومية بدقة استثنائية. ثم يمكنها تشكيل الأنابيب ليتم ضبطها بالضبط كما يجب أن تكون. تقوم الآلة بثني الأنابيب وتضخيمها وتشكيلها إلى الحجم الدقيق الذي ستحتاجه للاستخدام. عندما يتم تصنيع طرفي الأنابيب الألمنيومية بدقة كهذه، يمكنها العمل بكفاءة أكبر واستمرار العمل لفترة أطول. هذا أمر حاسم للكثير من الصناعات حيث تحتاج هذه الأنابيب إلى أن تكون متينة وأداءً جيدًا لمنتجاتها.

لدى ماكينة فيديت العديد من المزايا، لكن واحدة من أكثر خصائصها تميزًا هي السرعة التي يمكن بها إنتاج أنابيب الألمنيوم. يمكن لهذه الآلة إنتاج 100 أنبوب في الدقيقة! هذا يمكّن الشركات التي تحتاج إلى إنتاج عدد كبير من الأنابيب من القيام بذلك في فترة زمنية قصيرة. الإنتاج السريع يوفر الوقت والمال للشركات، وهو أمر حاسم في هذا العالم السريع الخطى. عندما تستطيع الشركات إنتاج المزيد من الأنابيب بهذه السرعة، يمكنها أيضًا تحقيق رضا العملاء بشكل أفضل.

حسنًا، هناك خاصية أخرى من ماكينة فيديت وهي أنها تتيح للشركات صنع أطراف أنابيبها بأشكال خاصة وفريدة. بدلاً من وضع جميع المنتجات في نفس الحجم والشكل القياسي للأنبوب، يمكن للشركات تعديل أنابيبها وفقًا لمنتجاتها. هذه الخدمة المخصصة مفيدة جدًا للشركات التي ترغب في التميز عن منافسيها. بهذه الطريقة، باستخدام أشكال أنثروبودية، يمكنهم تقديم شيئًا فريدًا لعملائهم، مما يساعدهم على النجاح في السوق.

تكنولوجيا تشكيل النهاية تعتبر أيضًا تقنية حيوية لأنها تسهّل استخدام أنابيب الألومنيوم. يمكن للماكينة فيديت تقليل عدد الاتصالات في المنتج، مما يقلل من خطر التسرب والانكسار. أقل عدد من الاتصالات يعني أن المنتجات تكون أكثر متانة وتتطلب صيانة أقل على مدار عمرها.对企业而言، هذا خبر جيد لأن الصيانة الأقل تعني توفير المزيد من المال لتركيزه على أعمال أخرى أساسية.

ماكينة أنابيب الألومنيوم من فيديت هي ماكينة متعددة الوظائف ومُستخدمة بشكل كبير. عشر حقائق لم تكن تعرفها: يمكنها توسيع الأنابيب، تضييقها، تقليل حجمها، توسيعها، عمل زخارف عليها وتشكيلها بطرق مختلفة. ستستفيد الشركات التي لديها أشكال منتجات معينة كثيرًا من هذه المرونة. سواء كان الشكل بسيطًا أو معقدًا، فإن ماكينة البوليش من فيديت يمكن أن تساعد في الوصول إلى ذلك.

نحن نقدم لك آلة تشكيل نهاية أنبوب الألمنيوم لمعدات معالجة الأنابيب، حيث نوفر مجموعة متنوعة من المعدات لتلبية احتياجاتك. عملنا في مجال المعدات الآلية لمعالجة الأنابيب لأكثر من 10 سنوات ونستطيع تقديم أكثر من 1000 نموذج تصميم غير قياسي. بعد فهم شامل لاحتياجات العميل، سيقوم فريق المبيعات ذو الخبرة بتقديم خدمات مخصصة. يتم اتباع عملية التخطيط للمشاريع لتصنيع وضبط معداتنا. يمكن للعميل متابعة عملية التجميع والضبط عبر الإنترنت في أي وقت. بعد قبول العميل للمعدات، سيتم إجراء فحص الخروج بالكامل وفقًا لإجراءات تسليم المنتجات للتأكد من دمج المعدات بسرعة في عمليات الإنتاج في مصنع العميل. لدينا سجل كامل للمعدات والبيانات. يتم حفظ بيانات معدات العميل بشكل مستندات وأيضًا على الورق. تحديث القوالب يتم عن طريق تقديم الرسومات أو التخصيص. الدعم الفني ما بعد البيع مقدم بواسطة فريق خبرائنا.

سوتشو VEDETTE هي واحدة من الشركات الرائدة في مجال معدات معالجة الأنابيب، خاصة في ما يتعلق بآلات تشكيل نهاية أنابيب الألمنيوم. تولي الشركة أهمية كبيرة للابتكار التكنولوجي، البحث والتطوير، وقد أطلقت منتجات جديدة تنافسية لتلبية المتطلبات المتغيرة باستمرار للسوق. نحن ملتزمون بتقديم حلول خبيرة تشمل استشارات ما قبل البيع، الدعم الفني أثناء البيع، والدعم بعد البيع. هذا يضمن لعملائنا الحصول على حلول سريعة وكفiciente. منتجاتنا تُستخدم بشكل واسع في مختلف الصناعات. سوتشو VEDETTE، وهي واحدة من أكبر مصنعي معدات معالجة الأنابيب، هي الخيار الأفضل للمستخدمين.

تُضمن آلة تشكيل نهاية أنبوب الألمنيوم الجودة العالية والاستقرار في جودة منتجاتنا. نلتزم بمبدأ أولوية الجودة، بالإضافة إلى اتخاذ خطوات أخرى مثل السيطرة على المصدر ومراقبة عملية الإنتاج والتحسين المستمر. في المستقبل، سنواصل التمسك بمبدأ أولوية الجودة. كما سنستمر في تحسين مستوى المنتجات والخدمات لتقديم المزيد من القيمة لعملائنا.

شركة سوتشو فيديت للتجهيزات الصناعية المحدودة، تأسست في عام 2011، وتقع في الجنوب الغربي من مدينة سوتشو، بالقرب من آلة تشكيل نهاية أنابيب الألمنيوم، وهي مركز ابتكار في تصنيع آلات تشكيل نهاية أنابيب الألمنيوم. إنها شركة تقنية عالية لديها أكثر من 10 سنوات من الخبرة في البحث والتطوير، التصنيع وتعديل خطوط الإنتاج الآلية. في وقت إطلاقها في ديسمبر 2022، حصلت على 31 براءة اختراع لنماذج عملية و10 براءات اختراع متعلقة بالمعدات. يتم قبول معداتها بشكل جيد محليًا ودوليًا، ولديها عملاء في جميع أنحاء العالم. تتبع الشركة مهمتها الأساسية بتقديم منتجات وخدمات ذات جودة عالية للعملاء، وهي ملتزمة بأن تكون رائدة في مجال التقدم التكنولوجي لمعدات معالجة الأنابيب في الصين.