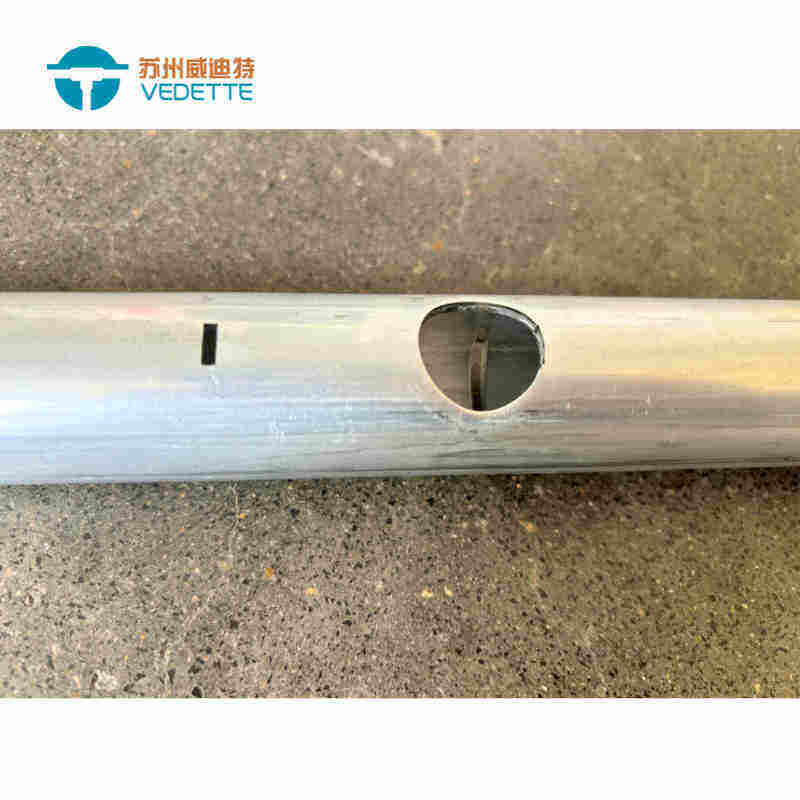

The tubes punching is a special method of creating holes in the tubing. This is an incredibly useful fast and easy hole-machining technique. Tube punching is perfect if you are wanting to save some time and money! This method is suitable for various materials and can be modified to address different requirements according to your projects.

It is very fast and able to create holes in tubes within no time. Tube Vedette Punching machine is another best thing because it can also be done using the machine. That equates to less labor which is needed by humans, which can save even more time and money for businesses!

Opting for tube punching in your projects means you do not only save time but also money. The automated methodologies presented here reduce the need for numerous laborious workers, such a trait that eases or diminishes expenses. Vedette Aluminum tube punching machine is usually high-definition when it comes to performance so, you save your money in the long run.

Tube punching is one of the best options because it makes holes which are so exact. The holes which are drilled are always the same size and this is very important for businesses where uniform results must be achieved. Tube punching is also able to provide holes in varying sizes for use across a wide range of requirements and applications.

Another important thing about tube punching is certainly safety! This process does not make sharp edges or burrs which can be a hazard for our workers. Due to this, Vedette Automatic feeding punching machine is a reliable choice for businesses. The synthesis can be tuned for other materials should you require applications in different industry requirements.

Tube punching is a process which can significantly improve the ability of businesses to produce more products in less time. Multi-hole punching machine is a faster and very efficient process of hole making than other older method to make holes, which takes the less time in comparison with past. This increased efficiency will enable businesses to produce more products in a fraction of the time.

Tube punching is advantageous because it may be customized for a variety of applications. The Punching and pulling machine process can be adjusted to practically any kind of project, depending on the material and size of tubes used. The versatility of this also makes it a good fit for types of businesses that need custom hole patterns.

We are the one-stop supplier for pipe processing equipment, offering a range of Tube punching to satisfy your needs. We have been working on the field of automation equipment for pipe processing since more than 10 years, and have over 1,000 design concepts that are not standard. Our sales professionals are experienced and can tailor solutions based on an in-depth understanding of the needs of customers. Our equipment is designed and debugged according to the project plan. The process of assembly and debugging can be seen online by the customer at any time. Once the equipment is accepted by the customer, they'll conduct an the exit inspection in accordance with the process of exit delivery to ensure that the equipment can be promptly incorporated into the customer's factory production processes. We have an efficient data and equipment archiving system. The customer's data equipment is preserved both in documents and in paper. Mold updating can provide sketches or custom. We have a knowledgeable service department after sales and can provide after-sales cleaning and maintenance.

To ensure excellence and stability in product quality We adhere to the first principle of quality, and take other measures such as source control, monitoring the production process and Tube punching improvement. In the future we will adhere to the principle of quality first. We will continue to enhance the quality of our products and services, in order to provide customers with more value.

Suzhou Vedette Industrial Equipment Co., Ltd., founded in 2011, is located in Tube punching located near Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a technologically advanced national company with more than 10 years of experience in research, development, manufacturing, and customizing automation production lines. In December 2022, it held 31 utility model and 10 patents on inventions of equipment. The equipment is popular both domestically and internationally, with customers from all over world. The company abides by its mission to provide valuable products and services for its customers, and is committed to being a leader in the development of technological innovations for tube processing equipment in China.

Suzhou VEDETTE is a leading Tube punching of pipe processing equipment in the field. It places great emphasis on technological innovation, research as well as development, and has launched new products that are competitive to meet the ever-changing demands of the market. We're committed to provide you with expert solutions that include pre-sales consulting as well as sales technical assistance and after-sales support. This ensures that our customers get prompt and efficient solutions. Our products are broadly applicable to different industries. Suzhou VEDETTE which is a major manufacturer of equipment for pipe processing is the best choice for users.