Did you ever consider how metal pipes are created? Metal pipes are critical to the construction of structures such as buildings and bridges, which we see every day. Many structures would not be excellent or safe without these pipes. This Vedette Cutting machine is where a CNC pipe punching machine comes in.

CNC stands for Computer Numerical Control, which is how a machine is directed by a computer. This implies that the machine can do its job with extreme precision and effectiveness. CNC pipe punching machine is a tool that may help create holes in metal pipes much more quickly and simply. Before the advent of CNC machines, employees were forced to punch each hole themselves. This Vedette straight pipe cutting machine was a lengthy and laborious task with insufficient accuracy. holes were punched in the wrong places. Pipe punching now consumes less time and is more precise. CNC punching may additionally that the holes punch in the proper locations. The machine can now create a hole in the proper location by striking the punch. This saves time and allows everyone to do their job better. * Make It Count, Every Time. CNC pipe punching machines are extremely helpful since they that the holes are punched in the correct location whenever. The computer dictates the machine, so the machine drills the hole in the right location. It’s useful while constructing buildings or bridges.

If you would like to get more done in less time and create the components faster than ever, then why not use a CNC pipe punching machine. Because the machines can continue to work without interruption, other important tasks around them are being done as they punch holes. This saves time and money for companies that can produce more pipes at a faster pace. Well, Vedette Single/double pipe clipless cutting machine because the machine can do all by itself and there is no more need for as many operators to work it. This saves companies money and ensures that workers can concentrate on other tasks that need their attention.

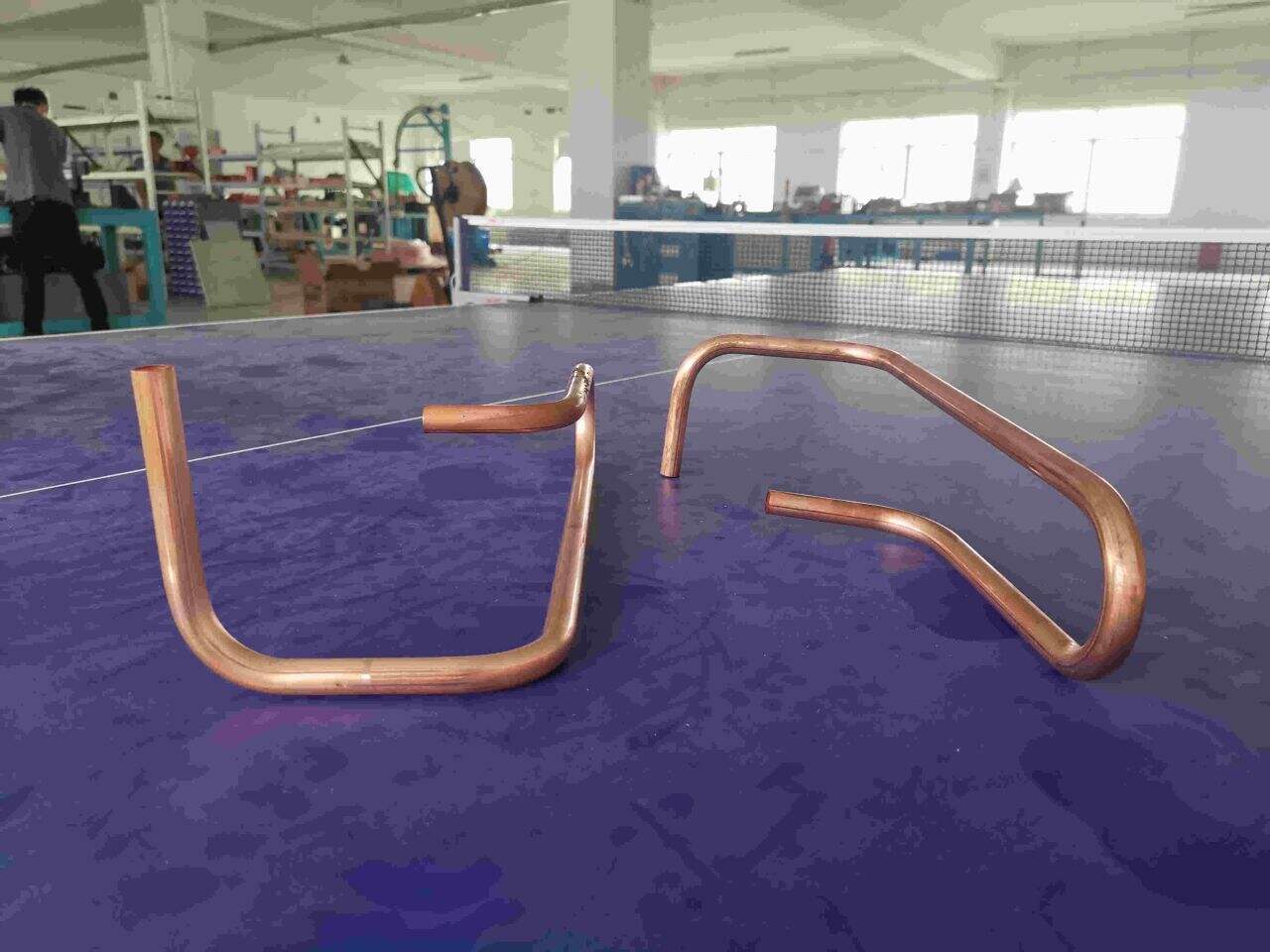

The CNC pipe punching machine makes it easier to take this process even further. The ability to make complex shapes and designs, that are otherwise difficult or impossible by hand. Because it is computer-controlled, the machine can move with great accuracy and even punch holes in elaborate patterns. The doors this Four-tube clipless cutting machine technology is opening for builders and designers to come up with creative ways in which buildings (and other structures) can be built. CNC machining enables workers to materialize their innovative designs into reality, which was not achievable in the past.

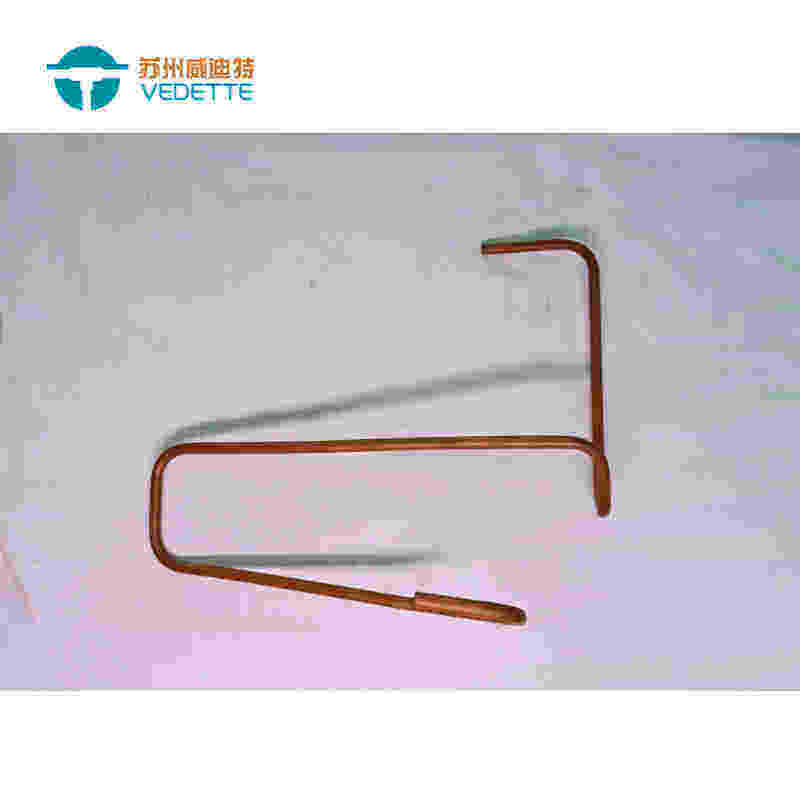

Finally, the CNC pipe punching machine is essential for making metal pipes. It makes work smoother and enables the workers to create perfect pipes every time. With just one click, the machine also becomes a time-saver for corporates that is a big win in the workaholic world. Additionally, copper pipe punching machine it provides workers with the ability to create novel configurations that might not have been achievable in previous systems. The more cutting edge technology we possess makes the process of building better and rejuvenates excitement in how things could be built in the construction industry.

We are the one-stop supplier for equipment to process pipes providing a range of equipment to meet your needs. We are focusing on the field of pipe processing automation equipment since more than 10 years and are able to offer more than 1,000 non-standard design schemes. Experienced sales projects will customize services following a thorough analysis of customer demands. Our equipment is produced and developed according to the Cnc pipe punching machine. The process of assembly and debugging can be seen online by customers at any time. They will conduct an exit inspection strictly in line with the process for delivering the exit once the equipment is accepted so that the equipment can be quickly integrated into the factory production tasks of the customer. We have an archive system for data and equipment system that is completely reliable. All equipment information of customers is preserved in paper files and electronic files. Mold updating can provide illustrations or Customization. After-sales services are provided by our professional team.

Cnc pipe punching machine will always keep quality of our products as the mainstay by ensuring that we control the source manufacturing process monitoring, source control constant improvement, among other things in order to guarantee the high-quality and durability of the product. We will continue to adhere this principle in the future and continue to improve our products and services in order to provide greater value to customers.

Suzhou VEDETTE, as a leading Cnc pipe punching machine manufacturer in the market, puts the highest importance to technological innovation and investment in research and development, and continues to launch new products that compete to meet the increasingly diversified requirements of the market. We adhere to the quality of life, customer satisfaction as the primary objective and provide all the professional services covering pre-sales consulting, sales technical support, after-sales service, and ensuring that customers get the benefit of timely and professional technical assistance and solutions. Our products can be applied to a variety of industries. Suzhou VEDETTE which is a major manufacturer of pipe processing equipment is the most suitable choice for those who need to use it.

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou and is a major center of technological innovation in the production of equipment. It is a top-quality national enterprise that has over 10 years of experience in research, development, manufacturing, and modifying automation production lines. As of Cnc pipe punching machine it was the holder of 31 utility models and 10 patents on inventions of equipment. Its equipment is highly regarded both in China and abroad, with many customers.