You ever seen a metal tube? We are surrounded by tubes! Everywhere from high-flying planes, cars on the roads, and even the air conditioning systems in our homes that make warm days more bearable. Because so much thought should be put into the use of tubes, processing tubes is a very important step in shaping them into something worthwhile for a variety of uses. This is where the tube punching machine come into play.

Tube processing machines come in a variety of types, and the latest generations of those machines are extremely strong and powerful. They employ cutting edge technology to process tubes rapidly and extremely efficiently. Machines that are the best part can be safe to use so workers can use this machine without risk that they can hurt the workers while working.

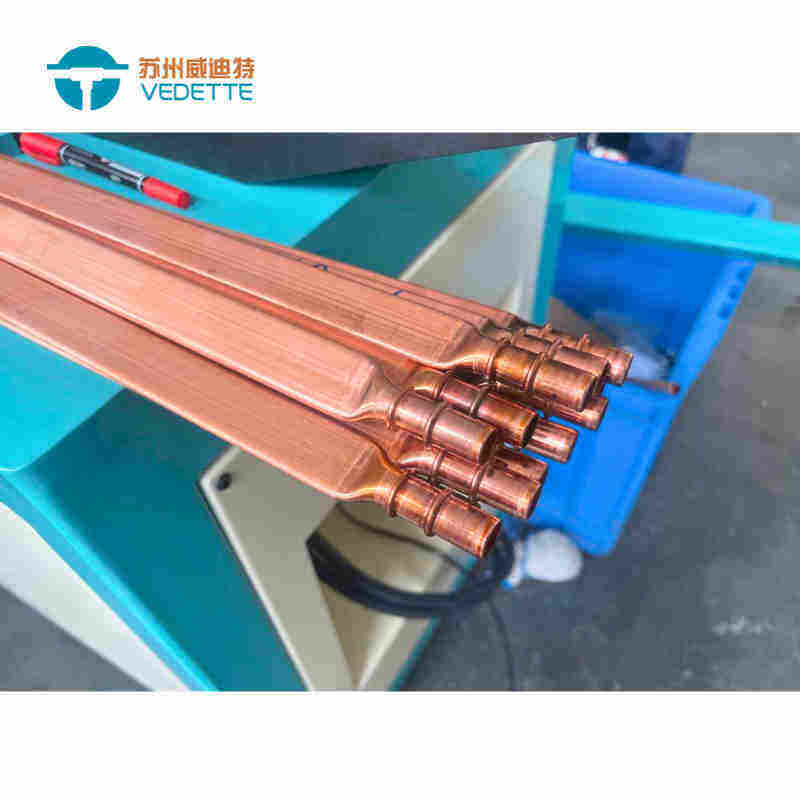

They are extremely powerful tools if looked at a tube punching equipment. They are solid, well-built blades designed to cut, bend and shape metal tubing in various configurations. This capability is also useful because these machines can drill holes in the tubes, which can be good for many different uses. Tube processing machines are used in numerous industries due to their incredible power and functions. For instance, they are used by companies to create the necessary pipes to drill for oil, tubes that are placed inside airplane engines and parts that go into cars.

Data gets better all the time, and tube processing machines are no different. These machines have become faster and more precise than ever with next-generation technology. Now, they can work with various metal tubes such as stainless steel and aluminium that is really tough and long-lasting.

The use of lasers in tube processing machines is in the emerging technologies. Because lasers cut tubes with great accuracy, they can do special and unique designs. This is why laser machines are best suited to industries that need quality parts, such as aerospace, which involves flying machines, and medical devices, that goes to health care and hospitals.

Perhaps the most notable benefit is the consistency that comes from using these machines. If tubes are processed by hand, it can create measurable differences in size and shape, which is less than optimal. However, tube processing machines are incredibly accurate and can all deliver the same parts in an identical size every time, so that everything fits perfectly.

While you will find varied types of tube processing machines available in the market, there are some critical features that the best ones have in common. They work hard, are fast, and very precise. These machines can also accommodate a wide range of metal tube types, allowing you to use them for several jobs.

To ensure stability and quality in the tube processing machines of our products We adhere to the premise of quality first and implement other measures such as control of the source as well as monitoring the process of production and continuous improvement. In the future we will continue to keep to the principle of quality first. We will continue to enhance the quality of our products and services to create greater value for customers.

Suzhou VEDETTE, as a prominent manufacturer of pipe processing equipment in the market, puts an tube processing machines importance to technological advancement as well as research and development investments, and continues to launch new products with market competitiveness to meet the ever-changing needs of the market. We place high-quality of life, and the customer satisfaction as the primary objective and provide an array of high-quality services that include pre-sales consultation, sales technical support, after-sales maintenance and to ensure that customers have access to of professional and timely technical assistance and solutions. Our products can be applied to various industries. For the users who need pipe processing equipment Suzhou VEDETTE is definitely the most reliable choice.

We are the one-stop supplier for tube processing machines, offering a variety of equipment to satisfy your needs. We have been working in the field of automation for pipe processing equipment for more than 10 years, and have over 1,000 designs that aren't standard. Our sales professionals are experienced and can tailor services after detailed understanding of customer demands. Our equipment is designed and tested according to the project plan. Customers can monitor the equipment's assembly and debugging progress online at any time. They will conduct an inspection at the exit point in strict compliance with the departure delivery process once the equipment is approved to ensure that the equipment can be quickly integrated into the factory production processes of the customer. We have a data and equipment archive system that is perfect. The information of the customer's equipment is kept both digital and paper formats. Mold updating may include illustrations or Customization. After-sales assistance is provided by our expert team.

Suzhou Vedette Industrial Equipment Co., Ltd., founded in 2011, is located in tube processing machines located near Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a technologically advanced national company with more than 10 years of experience in research, development, manufacturing, and customizing automation production lines. In December 2022, it held 31 utility model and 10 patents on inventions of equipment. The equipment is popular both domestically and internationally, with customers from all over world. The company abides by its mission to provide valuable products and services for its customers, and is committed to being a leader in the development of technological innovations for tube processing equipment in China.