When you need to make holes in metal, among your most useful tools is a hydraulic punch press. This one is where high pressure water jet comes to use with lot of strength and it forces a punch into metal hence the sheet bending in done. When your punch is nothing but a poke in the dark, what good will it do? Factories employ Vedette hydraulic Punching machine presses to make everything from vehicle components to metal furniture. These machines are important in the production of many products for every day use.

In the end, we want every worker to be able to do placements of this kind as quickly and easily as possible; that's why hydraulic punching presses exist. These are drilling holes very fast and with high preciseness, therefore its not wasting time, this is only one reason so worker will be capable of doing more work in less time. These machines can create these holes almost instantly so instead of it being a slow process to make every hole, you get them all done pretty quickly. It also consumes lesser energy to many other types of machines the hydraulic Punch Presses. This is also good for the world, and can save a business tens of thousands on energy. All these machines are significantly more eco-friendly, which translates into a gain for the ecology of the world and cheaper transportation.

Reason hydraulic punch presses are terrific — they can be used for a variety of tasks, in different industries. The Vedette Punching flanging machine are also quite versatile since they can create –based on the type-multiple hole sizes and shapes. It can also create Custom Shapes like rectangle and triangle. Their range in hole size is a benefit to any industry, because few other pieces of machinery are as interchangeable and well-suited for automotive manufacturers punching holes through heavy-duty steel or furniture production stamping out patterns along thinner alloys. One of the reasons that hydraulic punch presses are so popular for manufacturing is their versatility.

Companies should select the machines that are most appropriate for their particular jobs be more competitive and get better results in hydraulic punch presses! We have to look at a work when people works right size and features. In addition, they need a lot of equipment and their employees have to if the workers demand everywhere requires them provide extensive security training on how to operate devices safely. This is what allows the workers to operate punch presses so efficiently assuming they have adequate training and equipment. What Companies Can Gain By Using A High-Quality Hydraulic Punch Press

Metal as a material is one of the most used in mass industry; hence it brings along reliable, trustworthy machines. Hydraulic punch presses are very big and beefy, the Vedette machine Products itself will last many years to come with punches that can be of various types. This also makes the machinery all around reliable for companies to count on whenever there is a job that needs done, which can be any number of things these days. This is key, because it enables them to make the great products at base case with a fat tail of risk that the machines break or will require service constantly.

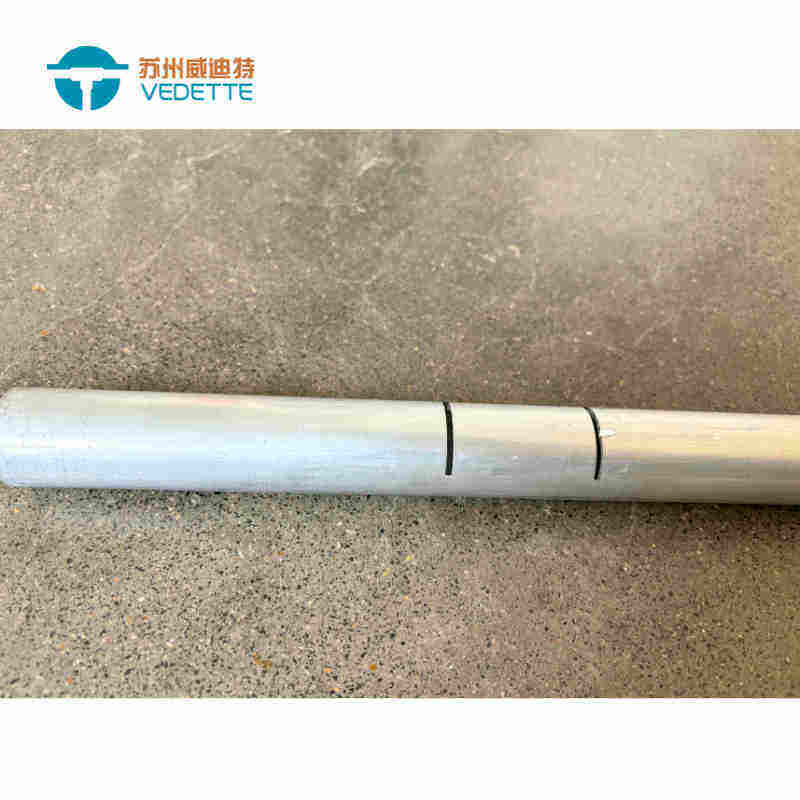

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the Hydraulic punch press. It puts a lot of emphasis on technological innovation, research as well as development, and has launched new products that are competitive in keeping up with the changing needs of the market. We place quality of life, as well as the customer experience as the core of our business, and offer the full spectrum of professional services that include pre-sales consultation and technical support for sales, after-sales support, to make sure that customers get the benefit of professional and timely technical support and solutions. Our products have a wide selection of applications to meet the needs of different industries in pipe processing. Suzhou VEDETTE, a leading manufacturer of equipment for pipe processing is the best option for users.

Hydraulic punch press will always keep quality of our products as the mainstay by ensuring that we control the source manufacturing process monitoring, source control constant improvement, among other things in order to guarantee the high-quality and durability of the product. We will continue to adhere this principle in the future and continue to improve our products and services in order to provide greater value to customers.

Hydraulic punch press company is manufacturing pipe processing automation equipment for more than 10 year and we have more than 1,000 designs that are not conventional. Once we have a complete understanding of the requirements of our clients and requirements, our experienced sales team can tailor the services to meet your needs. The project planning process is followed to manufacture and debug our equipment. Customers can watch the equipment assembly and debugging progress online anytime. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to ensure that the equipment is promptly incorporated into the customer's factory production tasks; We have a perfect data and equipment archiving system. The customer's equipment is preserved both in electronic and paper files. Mold updating can provide illustrations or Customization. After-sales support is provided by our experienced team.

Suzhou Vedette Industrial Equipment Co., Ltd., established in 2011, is located in the southwest of Suzhou, near the Hydraulic punch press, an innovation center in the manufacturing of Hydraulic punch press. It is a high-tech company that has more than 10 years of experience in research development, manufacturing and modifying automation production lines. At the time of its December 2022 launch, it had 31 utility model and 10 invention patents related to equipment. Its equipment is well-received nationally and internationally, with clients across the world. The company abides by its core mission of providing high-quality products and services to customers, and is committed to being a leader in the field of technological advancement for tube processing equipment in China.