If you consider the last time you inspected a metal object, you would realize that the object is very hot. That is the fun part to think about and to decide on which idea is worth the implementation. Vedette Punching machine is one of the machines which is used in the production and construction of metal objects. The miracle of the machine is that using computers it can punch the desired holes or any other shapes in that huge sheet metal base. Today let us face the fact that the world of manufacturing has gone very far with Technology and today let me share with you the extensive benefits that comes with CNC punching; this post contains a summary of the same.

The kind of punching that means it becomes highly advantageous. It is advantageous in a way because it saves one time and money that could have been used in the process of searching for the best materials. Before the appearance of CNC Punching several machines were very useful in creating holes on metal sheets. The working process took much time mainly because the workers transferred from one machine to another. Today, due to CNC Punching it is possible to do it much faster and easier and I think it is a great news for all companies.

The beauty of CNC Punching is that it provides the customer with the same look and feel of his or her products time and again. When people are handling activities manually then it is sure that chance of errors is very high. In some incidences, the hole or the shape may not be placed correctly or maybe the wrong size. While talking about solution it is possible to have bake or final product problem But in Vedette Punching flanging machine it is fully computerized hence it is very accurate. This makes it possible that each of the metal pieces, which the machine produces is constant and free from defects every time.

CNC Punching: shortens the process of production. It offers the ability to do more, and one such example is that instead of having to use one machine that just pokes a hole and another separate machine that just offers bending possibilities like an older product line, it is capable of doing the bending as well as punching holes into the metal that is involved all in one go.

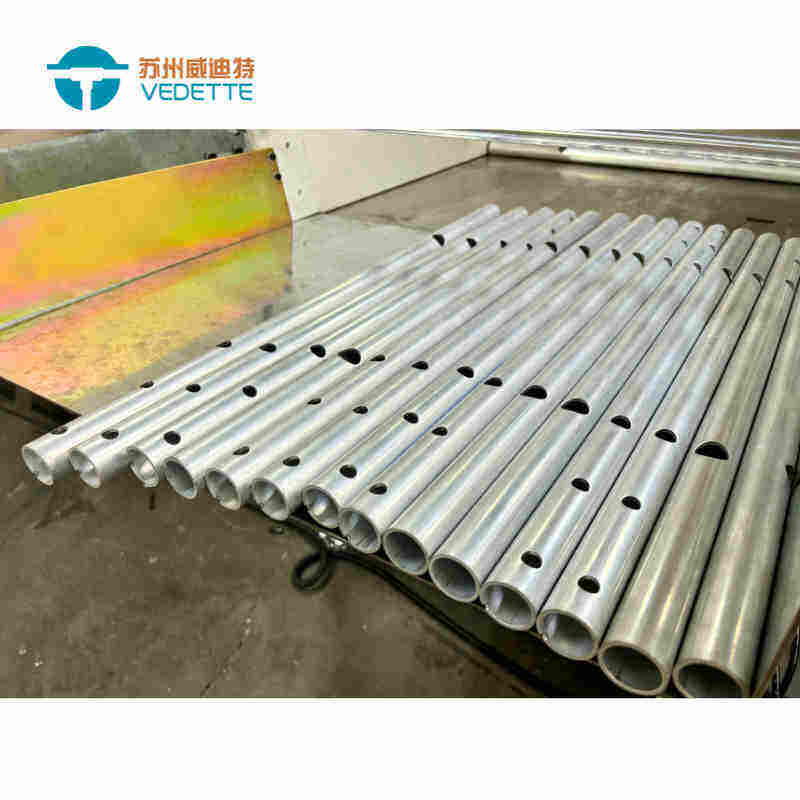

Activities that are accomplished by the CNC Punching machines can be prearranged. it has the flexibility of punching wholes and even shaping holes on profiles and even bending metals. In manufacturing Vedette Multi-spindle punching machine is a massive advantage because it all makes it easier hence minimizing the amount of equipment on the factory floor.

In order to do so you need 100 pieces and all the same size. These beads should be small and in an opaque color. In a factory tissue one has to tear out of the single sheet used in manufacturing each peace of towel individually. That is much wastage of material that is not friendly to the environment and also unfavorable for the financial status of the company. However, with the nesting feature of Vedette Multi-hole punching machine, computer fits that information for to arrange all these pieces on one large sheet of metal in order to maximize the sheet and to minimize the waste. Not only are we preserving materials; this is proving our planet conservation by lowering the consumption of natural resources.

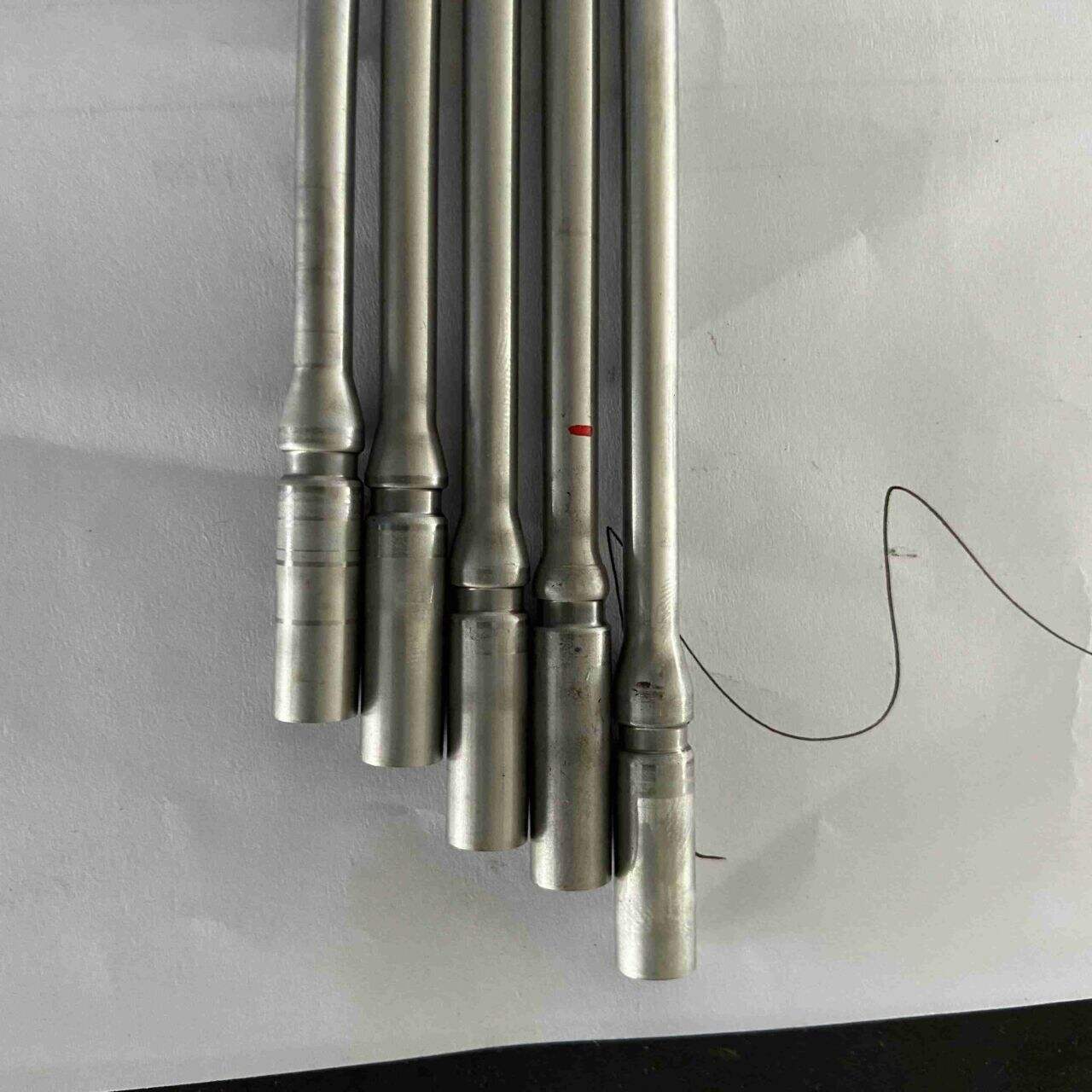

These are the machines that have been in industry scale in manner of metal object creation for tens of years. This is not only a much quicker way of the manufacturing process, but also in many other ways closer to the idea of the perfect process. Vedette Punching and pulling machine result in superior quality of produced goods and at the same time it reduces the overall time span.

Suzhou VEDETTE is a Cnc punching manufacturer of pipe processing equipment in the field. It places great emphasis on technological innovation, research and development, and launches new products that are competitive to meet the ever-changing needs of the marketplace. We believe in the quality of life and customer satisfaction as our primary goal, to provide you with a full range of professional services that include pre-sales consultation as well as sales technical support after-sales maintenance, to ensure that customers have access to of prompt and efficient technical support and solutions. Our products cover a wide application for the requirements of different industries in pipe processing. Suzhou VEDETTE, a renowned manufacturer of pipe processing equipment is the best choice for users.

To ensure stability and quality in the Cnc punching of our products We adhere to the premise of quality first and implement other measures such as control of the source as well as monitoring the process of production and continuous improvement. In the future we will continue to keep to the principle of quality first. We will continue to enhance the quality of our products and services to create greater value for customers.

We are your Cnc punching for equipment to process pipes offering a variety of equipment to fulfill your needs. We have been working on the field of automation equipment for pipe processing for over 10 years and are able to offer more than 1000 non-standard design patterns. After a thorough understanding of the customer's needs the experienced sales staff will tailor services. The planning process for projects is followed to manufacture and debug our equipment. The process of assembly and debugging can be viewed online by the customer at any point. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to make sure that the equipment is quickly integrated into the client's factory production processes. We have a flawless record of equipment and data. The information of the customer's equipment is preserved both in documents and in paper. Mold updating is a way to provide drawings or Customization. After-sales support is provided by our expert team.

Suzhou Vedette Industrial Equipment Co., Ltd., formed in 2011, is situated in southwest Suzhou in close proximity to Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a highly-tech national company with more than a decade's experience in research, development, manufacturing, and customizing automation production lines. At the time of its December 2022 launch, it was the holder of 31 utility models and 10 patents on inventions of equipment. The equipment it produces is highly Cnc punching both in China and around the world, with numerous customers.