It takes a lot of effort to fabricate with metal. The products we see every day are often the result of a great deal assessing and time. The process of fabrication can be simplified with a CNC Punch Press, or in your case maybe more than one. The full form of the CNC is Computer Numerical Control. Vedette Punching machine means a computer is running the machine, and guiding it to punch holes or even cut delicate patterns into some sheet-metal sheets. It is like having a little robot to do all the heavy lifting for you. If you believe it or not, the CNC Punch Press technology is quite unique and enable workers to accomplish a task in better yet faster way. By "faster" we mean the machine produces faster items. By “better”, of course, we mean everything is built properly the first time. There is a computer in the CNC Punch Press that ensures every hole and shape were fabricated being all dimensional correct. That brings more time for creating new things instead of fixing errors. Think of how much simpler it is when everything runs smoothly straight out the gate

CNC Punch Presses Are Updating the Face of Factory Production There were many thing back in the day that had to have been made by hand or was just slow from the old machines. Today, however, we are able to produce more products in a short time and at a higher quality using this revolutionary CNC technology. Businesses love this. When factories can churn out goods faster, then more people will purchase quicker and remain pleased

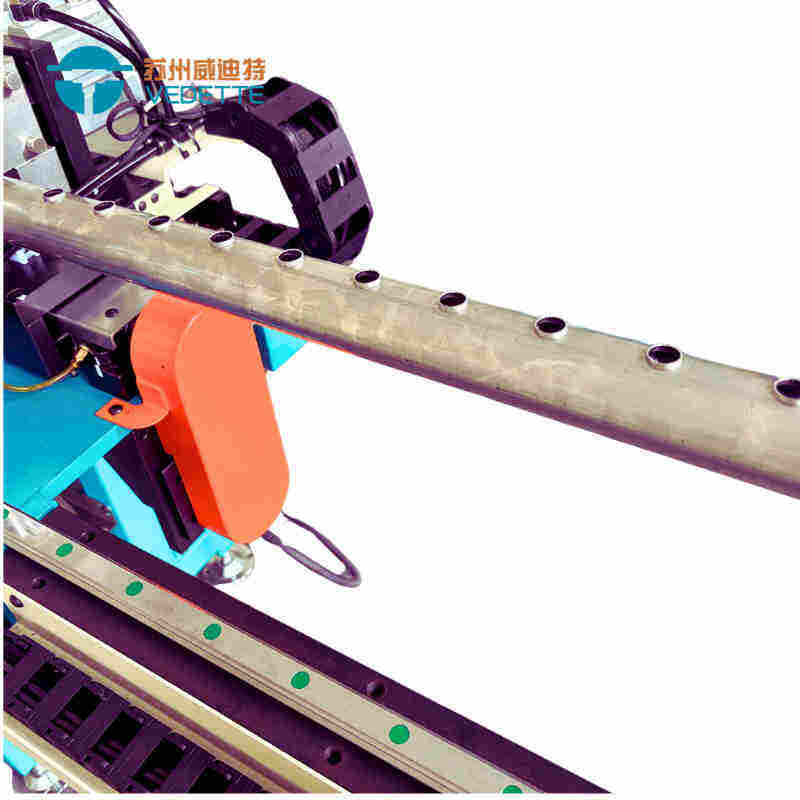

It make so many sense of making use of the CNC Punch Press technology. Sure there are so many other reasons, but a significant one is saving time and money. In fact, the traditional Vedette copper pipe punching machine require a long setup time and numerous workers are indispensable in order to operate them. That means more edger trolleys and therefore also costs! However, now with CNC technology, the machine can be brought and one person only required for its operation. This is an excellent advantage for corporations.

The best part about CNC Punch Presses is that they are capable of more than just punching holes. They are able to produce various shapes, designs and also letters! What this means is that businesses can now create, and ultimately produce even more bespoke and one-off creations. Krowne: The sky is the limit with this technology.

In the case of metal fabrication, we are basically referring to creating products out of various types of metals. Anything from metal signs hanging outside stores to car parts in motor vehicles. CNC Punch Press technology is immensely useful for making the metal fabrication process automatic. This Vedette single-shaft punching machine makes it possible for machines to work rather than people doing everything. Factories use machines to do the bulk of work for them, from which they save a tremendous amount on time and money at the same time ensuring that their products are in good quality as well. Introduction. CNC technology has allowed metal items to be produced faster, better and easier than it was in the past with decades of abilities.

Suzhou Vedette Industrial Equipment Co., Ltd., established in 2011, is situated in the southwest of Suzhou in close proximity to Taihu Lake, an innovation centrality in the production of equipment sector. With more than a decade of expertise in the development, research and production of tube processing equipment as well as different types of custom-designed production lines for automation, it is a national high-tech company that is involved in the development and production of automated, technological, and sophisticated equipment. As in December 2022 it had 31 utility model patents and 10 patents for inventions of equipment. Its equipment is well-received domestically and internationally, with clients across the world. The Cnc punch press is committed to its core mission of providing valuable products and services for its customers, and is committed to become a leader in the development of technological innovations for tube processing equipment in China.

We are the one-stop supplier for Cnc punch press, offering a variety of equipment to satisfy your needs. We have been working in the field of automation for pipe processing equipment for more than 10 years, and have over 1,000 designs that aren't standard. Our sales professionals are experienced and can tailor services after detailed understanding of customer demands. Our equipment is designed and tested according to the project plan. Customers can monitor the equipment's assembly and debugging progress online at any time. They will conduct an inspection at the exit point in strict compliance with the departure delivery process once the equipment is approved to ensure that the equipment can be quickly integrated into the factory production processes of the customer. We have a data and equipment archive system that is perfect. The information of the customer's equipment is kept both digital and paper formats. Mold updating may include illustrations or Customization. After-sales assistance is provided by our expert team.

We Cnc punch press adhere to the quality as the core by ensuring that we control the source, production process monitoring and continuous improvement as well as other methods, to ensure the excellence and reliability of the product. We will keep adhering to the quality-first principle into the future and improve our products and services in order to offer greater value to our customers.

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the industry. It places great emphasis on Cnc punch press, research as well as development, and has launched new products that are competitive to meet the constantly changing demands of the marketplace. We are committed to provide you with expert services that include pre-sales consultation and sales technical support and after-sales service. This will ensure that clients receive prompt and effective solutions. Our products can be applied for a wide range of industries. For users in need of equipment for pipe processing, Suzhou VEDETTE is undoubtedly the most reliable choice.