When I say chip free cutting machine, you obviously understand what it is right? If you don't, that's totally okay! Let me explain this in detail, and make your cutting process easier after reading this article. A mess-free cutting machine and this chip free thing is a tool used to cut, in general terms, different materials without leaving a swath of destruction in its path. This is done without any chips and debris. Vedette one of the reputed brands when it comes to making these Vedette Cutting machine. Let us understand about chip free cutting machine key five things.

Ever wanted to chop a piece of wood or a metal and it was so hard? It can be frustrating, right? However, when you use a chip free cutting machine it will be so much more fun. It also cuts materials very smoothly such that it makes cutting through butter look slow and cumbersome. With a specific easy-to-cut design, it comes with an ultra-sharp bladed edge. It cuts clean without leaving any jagged edges or slivers of material like other knives do, which is amazing!

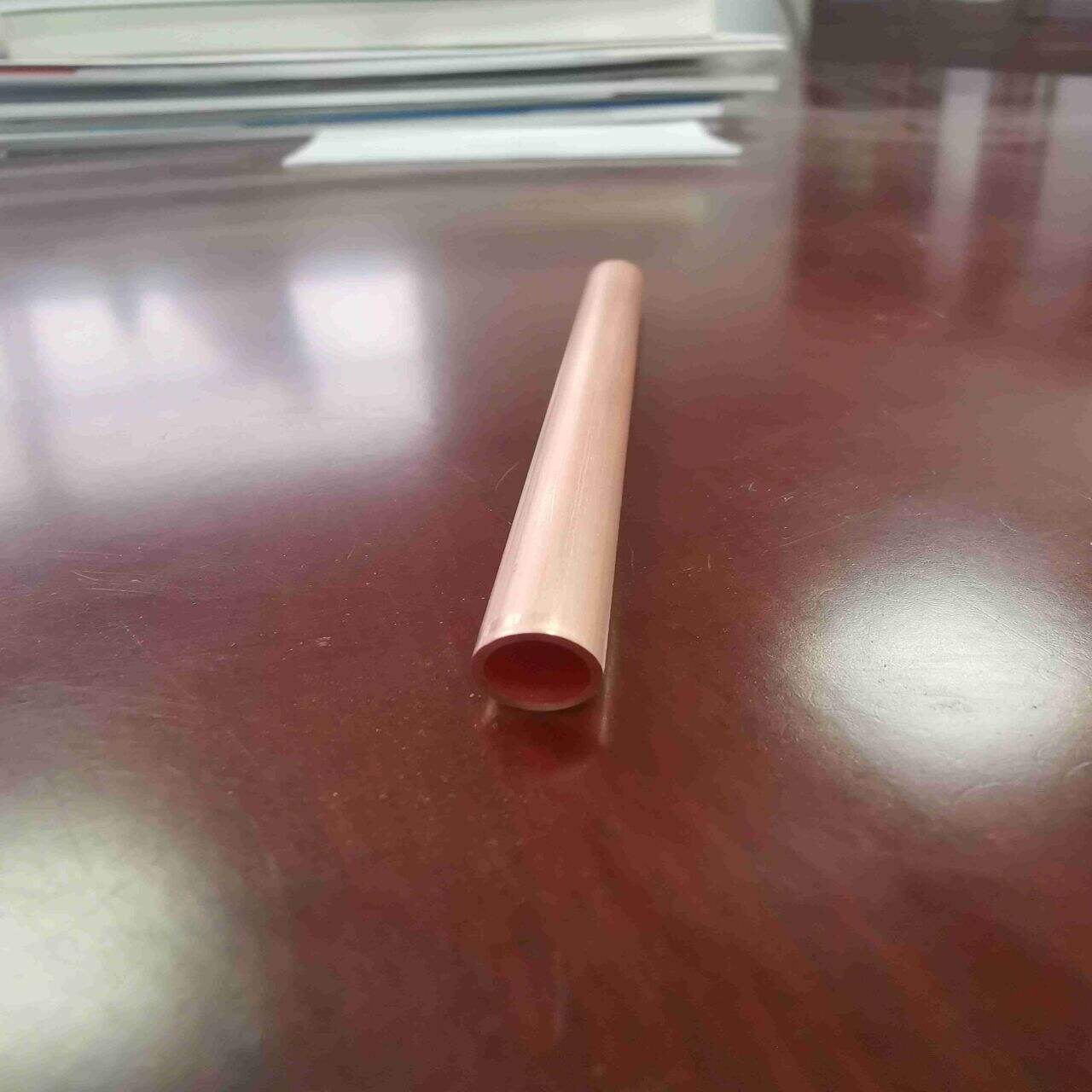

Chopping helps to discount but it results in so many messy pieces which is not cute at all! This makes a big mess not to mention those messy pieces can be dangerous for people around them. Well, Vedette Single/double pipe chipless cutting machine deploys a special technological arm to address this issue. With this advanced technology, it gives you crisp and clean cuts all the time you cut something. This translates well for your work: you can be working effectively without having to deal with the mess it leaves behind.

One of the hardest things about using a cutter is cleaning up after it has been used. Luckily with Vedette's chip free cutting machine you won't have to worry about cleaning the mess at all! A machine that literally leaves no messy pieces behind; it is built for clean cuts. It both saves you time and keeps your workspace safe and tidy. A neat working area means you can focus better on your work and keeps you more orderly.

Again—did you ever make a mistake, cut into the chips? The chips cover what you are cutting and it can get into the way making it difficult to see exactly how much material is being removed. This may result in inaccuracies and also a waste of materials, of which can be highly frustrating. Vedette Four-tube chipless cutting machine means there are no chips to think about! Which means that, you are able to view everything obviously and for this reason the slices is going to be much better without mistakes. No more distractions from things blowing away!

Are your cutting mistakes driving you to start from scratch? It can be very annoying! An automatic chip saw machine can help you work much faster and much better. This saw will make the smoothest cuts you could possibly ask for each and every time, allowing you to spend less time working on your projects while still getting the quality that you need. This means you can accept more assignments and even set up more contracts with new clients to increase your income even further. Just imagine doing them faster!

Suzhou Vedette Industrial Equipment Co., Ltd., established in 2011, is situated in the southwest of Suzhou in close proximity to Taihu Lake, an innovation centrality in the production of equipment sector. With more than a decade of expertise in the development, research and production of tube processing equipment as well as different types of custom-designed production lines for automation, it is a national high-tech company that is involved in the development and production of automated, technological, and sophisticated equipment. As in December 2022 it had 31 utility model patents and 10 patents for inventions of equipment. Its equipment is well-received domestically and internationally, with clients across the world. The Chip free cutting machine is committed to its core mission of providing valuable products and services for its customers, and is committed to become a leader in the development of technological innovations for tube processing equipment in China.

Our Chip free cutting machine has been manufacturing pipes processing automation equipment for more than 10 year and we have over 1,000 design plans that aren't conventional. After a thorough understanding of the needs of our customers and requirements, our experienced sales team will tailor services. Our equipment is produced and debugged according to the project planning process. Customers can monitor the equipment's assembly and debugging progress online at any time. Once the equipment is accepted by the customer, they'll conduct an the exit inspection in accordance with the exit delivery process to ensure that the equipment can be quickly put into the customer's factory production process. We have an efficient record of equipment and data. All data about equipment and customers are stored in paper files as well as electronic files. The mold updating service could be utilized to produce drawings or to provide Customization. After-sales assistance is provided by our professional team.

Suzhou VEDETTE is a Chip free cutting machine manufacturer of pipe processing equipment in the field. It places great emphasis on technological innovation, research and development, and launches new products that are competitive to meet the ever-changing needs of the marketplace. We believe in the quality of life and customer satisfaction as our primary goal, to provide you with a full range of professional services that include pre-sales consultation as well as sales technical support after-sales maintenance, to ensure that customers have access to of prompt and efficient technical support and solutions. Our products cover a wide application for the requirements of different industries in pipe processing. Suzhou VEDETTE, a renowned manufacturer of pipe processing equipment is the best choice for users.

We Chip free cutting machine adhere to the quality as the core by ensuring that we control the source, production process monitoring and continuous improvement as well as other methods, to ensure the excellence and reliability of the product. We will keep adhering to the quality-first principle into the future and improve our products and services in order to offer greater value to our customers.