การขึ้นรูปปลายท่อมีความสำคัญมากในระบบท่อที่ท่อเชื่อมต่อกัน โพสต์นี้จะพูดถึงการขึ้นรูปปลายท่อประเภททั่วไปและเหตุใดจึงมีความสำคัญ โดยเริ่มจากการขึ้นรูปปลายท่อคืออะไร จากนั้นเราจะครอบคลุมวิธีต่างๆ ในการขึ้นรูปปลายท่อ และการเรียนรู้วิธีต่างๆ เหล่านี้จะช่วยให้เชื่อมต่อได้อย่างน่าเชื่อถือ นอกจากนี้ เราจะตรวจสอบปัญหาทั่วไปบางประการที่อาจพบขณะทำ และวิธีบรรเทาปัญหาเหล่านี้โดยใช้เทคโนโลยีใหม่ เครื่องเจาะท่อสแตนเลส เป็นบริษัทที่ยอดเยี่ยมในการให้บริการโซลูชันการขึ้นรูปปลายท่อสำหรับอุตสาหกรรมต่างๆ มากมาย รับประกันคุณภาพสูง

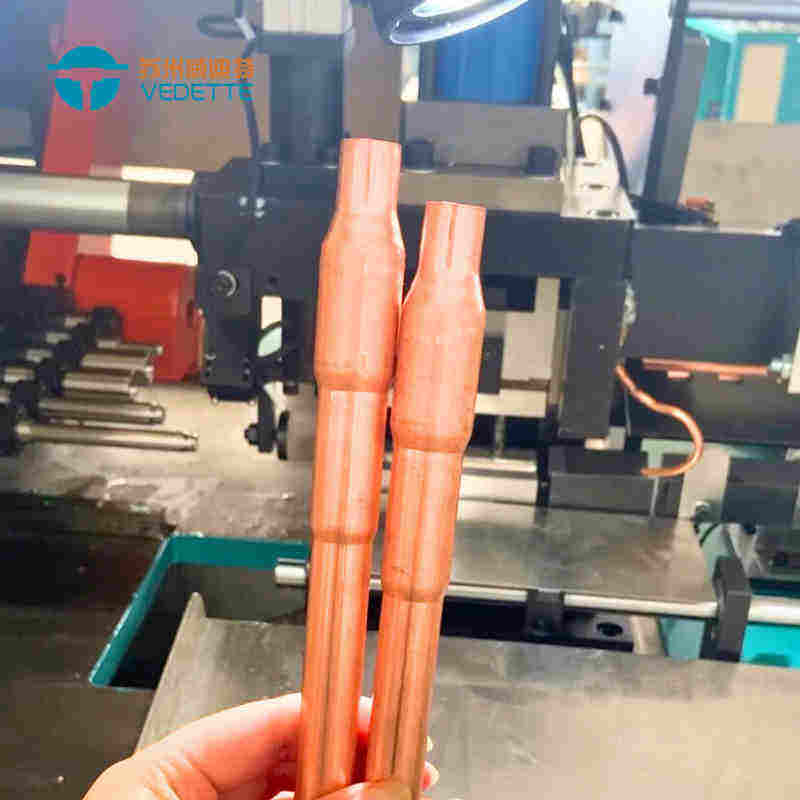

การขึ้นรูปปลายท่อ — กระบวนการที่เปลี่ยนรูปร่างของปลายท่อหรือท่อเพื่อให้พอดีกับท่อหรือส่วนอื่น ๆ กระบวนการนี้เป็นสิ่งสำคัญในหลาย ๆ ด้าน เช่น ระบบประปา รถยนต์ เครื่องบิน และการก่อสร้าง ปลายท่อที่ผิดรูปอาจทำให้เกิดการรั่วซึมหรือต้องแก้ไขให้ยุ่งยากยิ่งขึ้น ปลายท่ออาจขึ้นรูปได้หลายแบบ วิธีการขึ้นรูปทั่วไป ได้แก่ การขึ้นรูปปีก (การขึ้นรูปชิ้นส่วนโลหะอย่างรุนแรง) การขึ้นรูปลูกปัด (การทำให้ปลายแผ่นหรือท่อมีขอบยกขึ้น) การทำร่อง การรีด (การลดเส้นผ่านศูนย์กลางโดยใช้แรงกดตรงกลางเข้าไปในช่องว่างวงแหวน) และสิ่งเหล่านี้ใช้ในการขึ้นรูปตัวล็อกที่ทำจากสเตนเลสเกรดทหาร วิธีการเหล่านี้แต่ละวิธีใช้เพื่อจุดประสงค์เฉพาะและในสถานการณ์ที่แตกต่างกัน

การขึ้นรูปปลายท่อสามารถทำได้หลายวิธี และแต่ละวิธีจะต้องใช้เครื่องมือและอุปกรณ์เฉพาะ วิธีหนึ่งคือใช้ถัง เช่น การลอกและลิ้นไก่ โดยส่วนใหญ่มักจะจับคู่ท่อที่มีขนาดไม่เท่ากัน ซึ่งจะทำให้ดูเหมือนท่อสองเส้นที่ต่างกัน กลองจะเข้ากัน ในทางกลับกัน วิธีการขยาย/ลดขนาดใช้เพื่อปรับขนาดปลายท่อตรงข้ามเพื่อให้ต่อกับอุปกรณ์อื่นๆ ได้ง่ายขึ้น วิธีการข้างต้นทั้งหมดนี้สามารถนำไปใช้โดย Vedette ได้เช่นกัน เครื่องตัดท่อตรง ด้วยการปฏิบัติที่ดี ซึ่งจะทำให้ลูกค้ามีขอบเขตในการขึ้นรูปปลายท่อที่กว้างขวาง พวกเขาสามารถมั่นใจได้ว่าการเชื่อมโยงจะแข็งแรงและเชื่อถือได้ โดยใช้ขั้นตอนที่เหมาะสมสำหรับแต่ละกรณี

การขึ้นรูปปลายท่อเป็นงานสำคัญที่ต้องทำอย่างมุ่งมั่นและแม่นยำ ปลายท่อประกอบด้วยสองส่วนซึ่งต้องขึ้นรูปเข้าด้วยกันเพื่อให้การเชื่อมต่อมีรูปร่างคงที่

หากปลายท่อไม่ได้ติดตั้งอย่างถูกต้อง อาจทำให้เกิดการรั่วซึมหรือระบบท่อทั้งหมดจะอ่อนแอลง นั่นคือเหตุผลที่ความแม่นยำจึงมีความสำคัญ ในที่สุด Vedette ใช้เครื่องมือชั้นยอดและตรวจสอบให้แน่ใจว่างานได้รับการตรวจสอบอย่างเหมาะสม Vedette เครื่องดัดท่อ พิถีพิถันในการทำให้แน่ใจว่าทุกสิ่งทุกอย่างพอดีกันอย่างสมบูรณ์แบบเมื่อใดก็ตามที่เป็นไปได้ เนื่องจากจะทำให้เกิดปัญหาน้อยมากในภายหลัง

มีหลายสิ่งหลายอย่างที่อาจผิดพลาดได้เมื่อขึ้นรูปปลายท่อ ซึ่งหมายความว่าไม่ใช่เรื่องง่ายที่จะทำสำเร็จ ผลลัพธ์ที่ได้อาจแตกต่างกันไป ขึ้นอยู่กับประเภทของวัสดุที่ใช้ในการผลิต ความหนาของท่อที่ผลิต และสภาพแวดล้อมในการทำงาน ปัญหาทั่วไป ได้แก่ การย่น การงอ การแตกร้าว หรือขนาดที่ไม่ตรงกัน หากไม่ได้รับการแก้ไข ปัญหาเหล่านี้อาจทำให้เกิดความล่าช้าและค่าใช้จ่ายเพิ่มเติม Vedette นำเสนอโซลูชันที่เน้นลูกค้าเพื่อแก้ไขปัญหาเหล่านี้ และบริษัททำงานร่วมกับลูกค้าเพื่อระบุปัญหาที่อาจเกิดขึ้นกับลูกค้า ทำให้ลูกค้าสามารถให้บริการที่ดีที่สุดได้ด้วยการทราบว่าแต่ละโครงการอาจต้องการอะไร

เทคโนโลยีการขึ้นรูปปลายท่อแบบใหม่เป็นนวัตกรรมไม่กี่อย่างที่สามารถปรับปรุงระบบท่อได้หลายวิธี วิธีนี้จะช่วยเพิ่มประสิทธิภาพกระบวนการ และขึ้นอยู่กับงานที่ทำ ซึ่งอาจเร็วขึ้น แข็งแกร่งขึ้น และสุดท้ายก็ประหยัดขึ้นในบางกรณีในระยะยาว เทคโนโลยีนี้ช่วยให้ประกอบปลายท่อได้ดีขึ้นและลดข้อผิดพลาดอันเกิดจากการใช้เทคโนโลยีขั้นสูงได้ สุดท้ายแล้วเทคโนโลยีนี้จะช่วยยืดอายุการใช้งานของระบบท่อได้เมื่อทำข้อต่ออย่างถูกต้อง เมื่อลูกค้าทำงานร่วมกับ Vedette พวกเขาจะได้รับประโยชน์จากนวัตกรรมล่าสุดในอุตสาหกรรมเกี่ยวกับเครื่องมือและเทคโนโลยีการขึ้นรูปปลายท่อ ด้วยความร่วมมือในลักษณะนี้ พวกเขาสามารถผลิตระบบท่อที่ดีขึ้นและทนทานยิ่งขึ้นซึ่งทำงานได้ดีในระยะยาว

เราเป็นซัพพลายเออร์แบบครบวงจรสำหรับอุปกรณ์แปรรูปท่อซึ่งมีอุปกรณ์หลากหลายเพื่อตอบสนองความต้องการของคุณ เรามีประสบการณ์ด้านอุปกรณ์อัตโนมัติสำหรับแปรรูปท่อมานานกว่า 10 ปี และสามารถเสนอแนวคิดการออกแบบที่ไม่ได้มาตรฐานได้มากกว่า 1,000 แบบ ทีมงานขายที่ผ่านการฝึกอบรมอย่างเชี่ยวชาญสามารถปรับแต่งโซลูชันตามความเข้าใจอย่างลึกซึ้งถึงความต้องการของลูกค้า อุปกรณ์ของเราผลิตและถอดประกอบตามแผนโครงการ ลูกค้าสามารถตรวจสอบกระบวนการประกอบและแก้ไขข้อบกพร่องของอุปกรณ์ออนไลน์ได้ตลอดเวลา พวกเขาจะดำเนินการตรวจสอบก่อนส่งมอบตามขั้นตอนการส่งมอบที่เคร่งครัดเมื่ออุปกรณ์ได้รับการยอมรับ เพื่อให้สามารถขึ้นรูปปลายท่อในกระบวนการผลิตในโรงงานของลูกค้าได้ เรามีระบบจัดเก็บอุปกรณ์และข้อมูลที่สมบูรณ์แบบ ข้อมูลของอุปกรณ์ของลูกค้าจะถูกจัดเก็บทั้งในเอกสารและกระดาษ บริการอัปเดตแม่พิมพ์สามารถใช้ในการสร้างภาพวาดหรือปรับแต่งได้ เรามีทีมงานหลังการขายที่มีทักษะสูงซึ่งให้บริการทำความสะอาดและบำรุงรักษาหลังการขาย

เรามุ่งมั่นที่จะผลิตปลายท่อที่มีคุณภาพสูงเป็นเป้าหมายหลัก โดยทำให้แน่ใจว่าเราควบคุมการตรวจสอบแหล่งที่มาของกระบวนการผลิต การปรับปรุงอย่างต่อเนื่อง และมาตรการอื่นๆ เพื่อให้แน่ใจว่าผลิตภัณฑ์ของเรามีคุณภาพสูงสุดและสม่ำเสมอ เราจะยึดมั่นในหลักการนี้ต่อไปในอนาคตอันใกล้นี้ และจะปรับปรุงผลิตภัณฑ์และบริการของเราอย่างต่อเนื่องเพื่อมอบคุณค่าที่มากขึ้นให้กับลูกค้าของเรา

บริษัท Suzhou Vedette Industrial Equipment Co., Ltd. ก่อตั้งขึ้นในปี 2011 และตั้งอยู่ริมทะเลสาบ Taihu ที่สวยงามทางตะวันตกเฉียงใต้ของซูโจว และเป็นศูนย์กลางสำคัญของนวัตกรรมเทคโนโลยีในการผลิตอุปกรณ์ เป็นองค์กรระดับชาติที่มีคุณภาพสูงซึ่งมีประสบการณ์มากกว่า 10 ปีในการวิจัย พัฒนา ผลิต และปรับเปลี่ยนสายการผลิตอัตโนมัติ นับตั้งแต่การขึ้นรูปปลายท่อ บริษัทเป็นเจ้าของโมเดลยูทิลิตี้ 31 รายการและสิทธิบัตร 10 รายการสำหรับการประดิษฐ์อุปกรณ์ อุปกรณ์ของบริษัทได้รับการยกย่องอย่างสูงทั้งในประเทศจีนและต่างประเทศ โดยมีลูกค้าจำนวนมาก

Suzhou VEDETTE เป็นผู้ผลิตอุปกรณ์แปรรูปท่อขึ้นรูปปลายท่อในภาคสนาม โดยให้ความสำคัญอย่างยิ่งต่อนวัตกรรมทางเทคโนโลยี การวิจัยและพัฒนา และเปิดตัวผลิตภัณฑ์ใหม่ที่สามารถแข่งขันได้เพื่อตอบสนองความต้องการของตลาดที่เปลี่ยนแปลงอยู่ตลอดเวลา เราเชื่อมั่นในคุณภาพชีวิตและความพึงพอใจของลูกค้าเป็นเป้าหมายหลักของเรา เพื่อมอบบริการระดับมืออาชีพครบวงจรแก่คุณ ซึ่งรวมถึงการให้คำปรึกษาก่อนการขาย ตลอดจนการสนับสนุนด้านเทคนิคการขายและการบำรุงรักษาหลังการขาย เพื่อให้แน่ใจว่าลูกค้าสามารถเข้าถึงการสนับสนุนด้านเทคนิคและโซลูชันที่รวดเร็วและมีประสิทธิภาพ ผลิตภัณฑ์ของเราครอบคลุมการใช้งานที่หลากหลายสำหรับความต้องการของอุตสาหกรรมต่างๆ ในการแปรรูปท่อ Suzhou VEDETTE ผู้ผลิตอุปกรณ์แปรรูปท่อที่มีชื่อเสียงเป็นตัวเลือกที่ดีที่สุดสำหรับผู้ใช้