ท่อถูกใช้งานในอุตสาหกรรมและงานต่างๆ มากมาย ดังนั้นการผลิตท่อกลายเป็นภารกิจที่สำคัญมาก การผลิตนี้เกี่ยวข้องกับการสร้างรูปทรงของท่อโลหะ เช่น การงอ การโค้ง และการบิด ในอดีต ช่างฝีมือที่ผ่านการฝึกฝนจะทำสิ่งนี้ด้วยมือโดยใช้ทักษะและความชำนาญเฉพาะตัวเพื่อสร้างรูปร่างตามที่ต้องการ แต่ตอนนี้ด้วยการมาของเทคโนโลยี CNC การผลิตท่อดังกล่าวกลายเป็นเรื่องที่ดีขึ้นและเร็วขึ้นอย่างมาก หม้อไอน้ำแก๊ส : Computer Numerical Control ซึ่งหมายถึงการใช้คอมพิวเตอร์ในการควบคุมเครื่องจักรที่ทำงานได้เร็วและแม่นยำกว่าเดิม ในบล็อกถัดไปเราจะมาสำรวจว่า Vedette CNC ในการผลิตท่อได้เปลี่ยนแปลงความสามารถในการผลิตท่อของเราอย่างไรและช่วยในหลายภาคส่วนอย่างไร

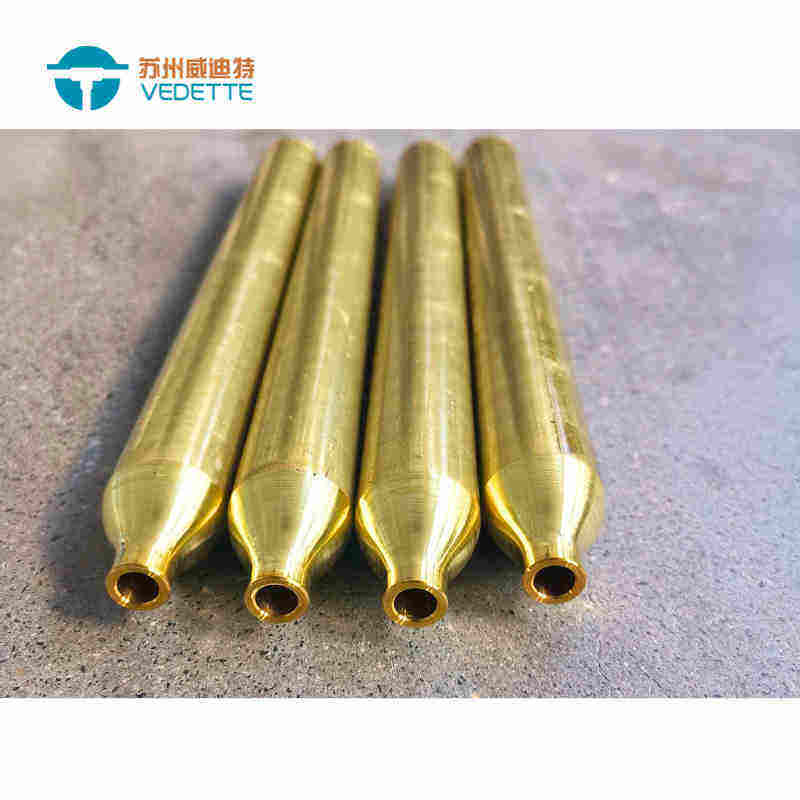

สิ่งประดิษฐ์นี้คือ Vedette CNC tube making และนั่นหมายความว่าเราสามารถทำท่อให้มีขนาดตามที่จำเป็นได้ โดยก่อนหน้านี้ไม่สามารถทำได้ด้วยมือเปล่า เนื่องจากเครื่องจักรเหล่านี้สามารถบิดและโค้งท่อได้หลายแบบที่คนทั่วไปทำไม่ได้ด้วยมือเปล่า นอกจากนี้เรายังสามารถปรับตัวและสร้างท่อที่มีความแม่นยำตามข้อกำหนดที่ลูกค้าต้องการได้จริง เครื่องกำเนิดไอน้ำแรงดันสูง สามารถใช้งานร่วมกับวัสดุหลายประเภทตั้งแต่เหล็ก ไปจนถึงอลูมิเนียมและทองแดง ความหลากหลายนี้เหมาะสำหรับงานทุกประเภทในอุตสาหกรรมต่างๆ เช่น เครื่องบิน รถยนต์ และแม้กระทั่งโรงพยาบาลที่มีความต้องการท่อเฉพาะเมื่อความปลอดภัยและการทำงานเป็นสิ่งสำคัญ

เครื่อง Vedette CNC สำหรับทำท่อ มีคุณสมบัติที่น่าทึ่งซึ่งสามารถผลิตท่อที่มีความแม่นยำสูงพร้อมรายละเอียดที่ซับซ้อนได้อย่างยอดเยี่ยม เครื่องจักร CNC เหล่านี้สามารผลิตชิ้นส่วนที่มีรายละเอียดซับซ้อน เช่น แหวนยอกและตาบนลูกเบ้า ซึ่งในอดีตจะเป็นไปไม่ได้ในการผลิตในรูปแบบที่ง่ายกว่านี้ โดยเฉพาะอย่างยิ่งในแผนการที่ต้องมีความแม่นยำมากขึ้นหรือน้อยลง นอกจากนี้ เครื่องกำเนิดไอน้ำสำหรับอุตสาหกรรม เป็นส่วนหนึ่งที่ได้รับการยอมรับมากที่สุดในด้านการผลิตดิจิทัลเนื่องจากมีระดับความซ้ำซ้อนสูง ซึ่งช่วยให้มั่นใจว่าสามารถผลิตหลอดคุณภาพสูงออกมาได้ซ้ำแล้วซ้ำเล่า สิ่งนี้ไม่ใช่เรื่องง่ายเสมอไปเมื่อมีมนุษย์เป็นผู้ทำงานทั้งหมด นอกจากนี้ การมีความสม่ำเสมอเช่นนี้มีความสำคัญอย่างยิ่งต่ออุตสาหกรรมเฉพาะทางที่วัสดุนำเข้าจำเป็นต้องมีเสถียรภาพและความแข็งแรงสูงเพื่อให้ได้ผลลัพธ์ที่มีคุณภาพ (การใช้งานปลายทาง)

หลอดถูกผลิตได้เร็วขึ้นและราคาถูกลงด้วยเครื่อง CNC ของ Vedette เครื่องเหล่านี้ถูกออกแบบมาให้ทำงานต่อเนื่องเป็นสัปดาห์หรือเป็นปี ในคำอื่น ๆ หมายความว่าพวกมันสามารถผลิตหลอดได้มากกว่าในเวลาที่น้อยกว่าเมื่อเทียบกับคนงานที่ทำหน้าที่เดียวกันด้วยมือ CNC เครื่องยังทำงานได้อย่างมีประสิทธิภาพเนื่องจากสามารถตัดหลอดหลากหลายขนาดได้โดยไม่จำเป็นต้องมีโรงงานหลายแห่งที่สร้างเครื่องสำหรับแต่ละขนาด ซึ่งอาจช่วยประหยัดเงินจำนวนมากสำหรับบริษัทที่ผลิตหลอดเหล่านี้ อีกทั้งยังลดความจำเป็นในการแทรกแซงของมนุษย์ เครื่องสร้างไอน้ำขนาดเล็ก , มันช่วยลดต้นทุนแรงงานและทำให้กระบวนการทั้งหมดถูกกว่าอีกด้วย

Vedette CNC tube making มอบท่อคุณภาพให้คุณในเวลาไม่นานและด้วยความแม่นยำสูง เครื่องจักรเหล่านี้ที่น่าทึ่งสามารถใช้งานได้ตลอด 24 ชั่วโมง จึงสามารผลิตท่อได้อย่างต่อเนื่องในเวลาเพียงเล็กน้อย นอกจากนี้ยังสามารถทำการโค้งหลายครั้งในขั้นตอนเดียว ช่วยประหยัดทั้งวัสดุและเวลา การทำงานที่เสถียรของ หม้อไอน้ำไฟฟ้าสำหรับอุตสาหกรรม การันตีว่าทุกท่อจะมีความสม่ำเสมอและมีคุณภาพสูง ซึ่งเหมาะมากสำหรับลูกค้าที่ใส่ใจในระดับความทนทาน อีกทั้งรุ่นนี้ยังเป็นสิ่งสำคัญสำหรับธุรกิจใด ๆ ที่ต้องการมุมมองเชิงลึกในระดับสูงเกี่ยวกับผลิตภัณฑ์

เราเป็นผู้จัดจำหน่ายครบวงจรสำหรับอุปกรณ์ประมวลผลท่อ นำเสนอช่วงของ Cnc tube forming เพื่อตอบสนองความต้องการของคุณ เราได้ทำงานในด้านอุปกรณ์อัตโนมัติสำหรับการประมวลผลท่อมาแล้วมากกว่า 10 ปี และเรามีแนวคิดการออกแบบมากกว่า 1,000 แบบที่ไม่ใช่มาตรฐาน ทีมขายของเราประสบการณ์สูงและสามารถปรับแต่งโซลูชันตามความเข้าใจอย่างลึกซึ้งเกี่ยวกับความต้องการของลูกค้า อุปกรณ์ของเราถูกออกแบบและทดสอบตามแผนโครงการ การประกอบและการทดสอบกระบวนการสามารถตรวจสอบออนไลน์โดยลูกค้าได้ตลอดเวลา เมื่ออุปกรณ์ได้รับการยอมรับจากลูกค้า พวกเขาจะดำเนินการตรวจสอบก่อนออกจากโรงงานตามกระบวนการส่งมอบเพื่อให้มั่นใจว่าอุปกรณ์สามารถรวมเข้ากับกระบวนการผลิตในโรงงานของลูกค้าได้อย่างรวดเร็ว เรามีระบบจัดเก็บข้อมูลและอุปกรณ์ที่มีประสิทธิภาพ ข้อมูลอุปกรณ์ของลูกค้าจะถูกเก็บรักษาไว้ทั้งในเอกสารและรูปแบบกระดาษ การอัปเดตแม่พิมพ์สามารถให้แบบร่างหรือกำหนดเองได้ นอกจากนี้เรายังมีแผนกบริการหลังการขายที่มีความรู้และสามารถให้บริการทำความสะอาดและการบำรุงรักษาหลังการขาย

บริษัทซูโจว เวด็ตต์ อินดัสเตรียล อีควิปเมนท์ จำกัด ก่อตั้งขึ้นในปี 2011 ตั้งอยู่ทางตะวันตกเฉียงใต้ของเมืองซูโจว ใกล้กับทะเลสาบไทหู ซึ่งเป็นศูนย์กลางนวัตกรรมในภาคการผลิตเครื่องจักร เป็นบริษัทแห่งชาติที่ใช้เทคโนโลยีสูง มีประสบการณ์มากกว่าทศวรรษในการวิจัย พัฒนา การผลิต และปรับแต่งสายการผลิตอัตโนมัติ ในเวลาที่เปิดตัวเดือนธันวาคม 2022 บริษัทได้รับสิทธิบัตรแบบประยุกต์ใช้งาน 31 รายการ และสิทธิบัตรการประดิษฐ์ 10 รายการเกี่ยวกับเครื่องจักร เครื่องจักรที่ผลิตมีความโดดเด่นในด้านการformingท่อ CNC ทั้งในประเทศจีนและทั่วโลก โดยมีลูกค้าจำนวนมาก

Suzhou VEDETTE เป็นผู้ผลิตเครื่องจักร CNC tube forming ในด้านอุปกรณ์ประมวลผลท่อ บริษัทให้ความสำคัญกับนวัตกรรมทางเทคโนโลยี การวิจัยและพัฒนา และเปิดตัวผลิตภัณฑ์ใหม่ๆ ที่มีความสามารถในการแข่งขันเพื่อตอบสนองความต้องการที่เปลี่ยนแปลงตลอดเวลาของตลาด เราเชื่อมั่นในคุณภาพชีวิตและความพึงพอใจของลูกค้าเป็นเป้าหมายหลัก โดยมอบบริการแบบครบวงจรที่ครอบคลุมตั้งแต่การให้คำปรึกษาล่วงหน้า การสนับสนุนทางเทคนิคหลังการขายและการบำรุงรักษา เพื่อให้มั่นใจว่าลูกค้าจะได้รับการสนับสนุนทางเทคนิคและการแก้ปัญหาอย่างรวดเร็วและมีประสิทธิภาพ ผลิตภัณฑ์ของเราครอบคลุมการใช้งานหลากหลายตามความต้องการของอุตสาหกรรมต่างๆ ในด้านการประมวลผลท่อ Suzhou VEDETTE ผู้ผลิตอุปกรณ์ประมวลผลท่อที่มีชื่อเสียงถือเป็นตัวเลือกที่ดีที่สุดสำหรับผู้ใช้

เพื่อให้มั่นใจในความเสถียรและความสามารถในการรักษาคุณภาพของผลิตภัณฑ์ เราปฏิบัติตามแนวคิดที่เน้นเรื่องคุณภาพเป็นหลัก และดำเนินการตามขั้นตอนอื่นๆ เช่น การใช้กระบวนการ Cnc tube forming ของแหล่งวัตถุดิบ การตรวจสอบกระบวนการผลิต และการปรับปรุงอย่างต่อเนื่อง ในอนาคตอันใกล้ เราจะยังคงยึดมั่นในหลักการที่เน้นเรื่องคุณภาพ และจะยังคงพัฒนาผลิตภัณฑ์และบริการของเรา เพื่อมอบคุณค่าที่มากขึ้นให้กับลูกค้า