Hej djeco! Trebate li znati kako tvornica može nešto proizvesti brzo i savršeno? A vrlo važan alat koji imaju u svom arsenalu su CNC cijevi prodajem stroj za savijanje. Jednostavnim riječima, CNC je "računalno numeričko upravljanje". Ova Vedette znači da uz pomoć računala možete brzo i precizno upravljati strojem.

Vedette najbolja stvar kod CNC strojeva za savijanje cijevi je ta što štede puno vremena i truda. Prije mnogo godina, zaposlenici su ručno savijali cijevi i bilo je potrebno manje energije za rad. Uz pomoć posebnog alata (DCM) oblikovali su cijevi i krakovi su se tek gradili. Međutim, sada s CNC strojem samo upišete mjere i on će se pobrinuti za sve cnc stroj za savijanje cijevi cijena za vas. Sada stvarno pojednostavljuje stvari. CurrentTimeMillis(); Također može stvoriti oblike i dizajne koje je gotovo nemoguće napraviti ručno, što je prilično cool.

I to ne sve materijale, čak i ako ih svaki put nepotrebno rasipate. ulaganjem u dobar CNC stroj za savijanje cijevi toliko ćete uštedjeti na sirovinama da je u jednom trenutku moguće potrošiti nulu. Računalo zna koliko je cijevi potrebno za svako savijanje, tako da nikada nećete potrošiti višak materijala. Ova Vedette je ključna jer rasipanje skupih materijala može biti skupo. Također, isti komad cijevi može se savijati u različitim smjerovima pomoću stroja tako da ne morate davati mnogo korištenih cijevi. A to štedi vrijeme, rad i troškove koji su vrlo bitni za svaku tvornicu kao i bilo što drugo.

CNC strojevi za savijanje cijevi potpuno su promijenili način na koji tvornice danas proizvode. Omogućuju brz i točan način obavljanja poslova. Umjesto zapošljavanja tona ljudi za ručno savijanje cijevi, potrebna je jedna osoba koja govori stroju što treba učiniti. To omogućuje drugim radnicima da se usredotoče na različite poslove u tvornici. Svatko radi zajedno na način koji je za njega najbolji i to omogućuje tvornici bržu proizvodnju više artikala što pomaže u održavanju svih opskrbljenih polica.

CNC stroj za savijanje cijevi u tvornici ima prednost u nekoliko svrha. Vrijeme je novac i štedi puno vremena! Također štedi novac jer ograničava otpad i osigurava da se sve ispravno izvede prvi put. Također čini stvaranje stvari jednostavnijim i preciznijim što je super zgodno. Osim toga, stvara složene lijevane oblike koje je teško izraditi u vašem proizvodnom pogonu koji ne bi bili mogući ručno kako bi mogli proizvesti više proizvoda. Ukratko, Prodajem cnc stroj za savijanje cijevi nužna su oprema za gotovo svaku tvornicu za poboljšanje kvalitete i učinkovitosti proizvodnje svojih proizvoda. Zašto Zero Blends Pomažu tvornicama da rade bolje, tako da mogu nastaviti proizvoditi sjajne proizvode za sve.

Mi, Cnc stroj za savijanje cijevi, pridržavamo se kvalitete kao jezgre osiguravajući da kontroliramo izvor, praćenje procesa proizvodnje i kontinuirano poboljšanje, kao i druge metode, kako bismo osigurali izvrsnost i pouzdanost proizvoda. I ubuduće ćemo se pridržavati načela kvaliteta na prvom mjestu i poboljšavati naše proizvode i usluge kako bismo ponudili veću vrijednost našim kupcima.

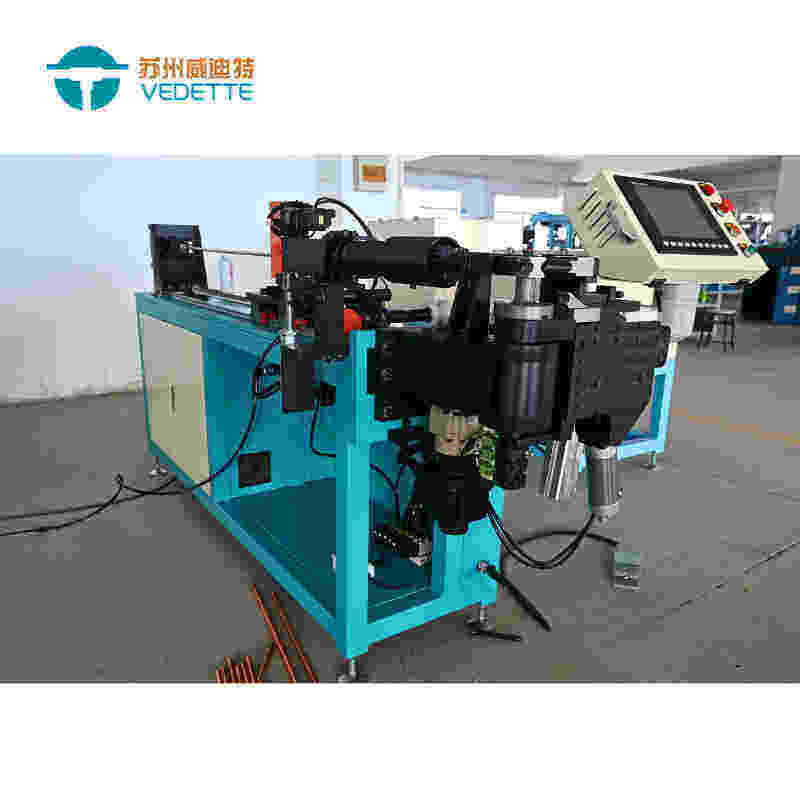

Suzhou Vedette Industrial Equipment Co., Ltd., osnovana 2011., nalazi se na jugozapadu Suzhoua u neposrednoj blizini jezera Taihu, središnjeg mjesta inovacija u sektoru proizvodnje opreme. S više od desetljeća stručnosti u razvoju, istraživanju i proizvodnji opreme za obradu cijevi, kao i različitih vrsta proizvodnih linija za automatizaciju po narudžbi, to je nacionalna visokotehnološka tvrtka koja je uključena u razvoj i proizvodnju automatiziranih , tehnološka i sofisticirana oprema. U prosincu 2022. imao je 31 patent za uporabne modele i 10 patenata za izume opreme. Njegova je oprema dobro prihvaćena u zemlji i inozemstvu, s klijentima diljem svijeta. Cnc stroj za savijanje cijevi predan je svojoj temeljnoj misiji pružanja vrijednih proizvoda i usluga svojim klijentima, te je predan tome da postane lider u razvoju tehnoloških inovacija za opremu za obradu cijevi u Kini.

Tvrtka CNC strojeva za savijanje cijevi proizvodi opremu za automatizaciju obrade cijevi više od 10 godina i imamo više od 1,000 dizajna koji nisu konvencionalni. Nakon što potpuno razumijemo zahtjeve i zahtjeve naših klijenata, naš iskusni prodajni tim može prilagoditi usluge vašim potrebama. Prati se proces planiranja projekta za proizvodnju i otklanjanje pogrešaka naše opreme. Kupci mogu u bilo koje vrijeme online gledati kako napreduje sklapanje opreme i otklanjanje pogrešaka. Nakon što kupac prihvati opremu, izvršit će izlazne inspekcije u potpunom skladu s postupkom izlazne isporuke kako bi osigurali da je oprema odmah uključena u kupčeve tvorničke proizvodne zadatke; Imamo savršen sustav arhiviranja podataka i opreme. Oprema kupca čuva se u elektronskim i papirnatim datotekama. Ažuriranje kalupa može pružiti ilustracije ili prilagodbu. Podršku nakon prodaje pruža naš iskusni tim.

Suzhou VEDETTE, kao vodeći proizvođač CNC strojeva za savijanje cijevi na tržištu, najveću važnost pridaje tehnološkim inovacijama i ulaganju u istraživanje i razvoj te nastavlja lansirati nove proizvode koji se natječu kako bi zadovoljili sve raznolikije zahtjeve tržišta. Pridržavamo se kvalitete života, zadovoljstva kupaca kao primarnog cilja i pružamo sve profesionalne usluge koje obuhvaćaju pretprodajno savjetovanje, prodajnu tehničku podršku, usluge nakon prodaje i osiguravamo da kupci dobiju korist od pravovremene i profesionalne tehničke pomoći i rješenja . Naši se proizvodi mogu primijeniti u različitim industrijama. Suzhou VEDETTE koji je veliki proizvođač opreme za obradu cijevi najprikladniji je izbor za one koji je trebaju koristiti.