Machines take a crucial part in helping workers do their jobs in modern factories. Such machines simplify and speed up tasks. A stainless steel pipe punching machine is an example of the kind of specialty machinery used in many different factories. This is a strong machine that is specially designed to work in harsh conditions without having to breakdown. So, let’s get an insight into why are these machines so important and how do they improve factories to work efficiently and seamlessly.

How These Machines Assist Factories

High production efficiency: Stainless steel pipe punching machine can process more products with less time, which makes the factories to be more efficient. It machines holes and shapes from metal tube. This step is essential in the creation of many products we use on a daily basis. With these machines, factories can carry out these vital steps with speed and precision. This saves a significant amount of time as these machines can punch, cut, and drill holes into metal pipes significantly quicker than a human could manually.

But one of the best things about these machines is they can punch lots of holes at once. This means that, rather than making a single hole at a time, the machine can create multiple holes in a single pass. These machines are also capable of creating holes that are shaped differently and have different sizes. This versatility makes them ideal for various types of projects, and allows factories to churn out much higher quantities of goods in less time.

Strong and Durable Machines

It is very strong and durable, and the machine used in punching stainless steel pipe will provide long service life. They’re designed for heavy work on crowded factory floors. These machines are made from quality stainless steel, so they do not easily rust. This matters because it enables the machines to be more durable and perform better in rugged environments. And if a part of the machine does break, it can be changed out relatively easily, since the parts can be swapped without too much of a hassle.

These machines are capable of working on even thick metal pipes. They are made to break through rigid material and not fail or get damaged. This capability to perform heavy-duty work is what makes them such vital apparatuses for current production lines that require solid machines to keep creation inclining.

Better Workflow in Factories

Factory Collaboration & Coordination Enhancement with Stainless Steel Pipe Punching Machines Using these machines allows factories to minimize waste, which is when materials are not used correctly and discarded. This aids in saving time and resources ensuring a smoother production process. This also ensures that these machines continuously produce quality product as the items are made to specifications that customers demand and expect.

And these machines can also cooperate besides the per-existing machines in the same factory. This helps in an overall smoother workflow in which everything coordinates seamlessly. Information collected from these machines is also tremendously helpful. Of course, a few changes in the production make factory managers tend to be less than ideal for that must be the same in all points. Factories can save time and money through improving their workflow and supply chain management.

Jobs that Belong to Versatile Machines

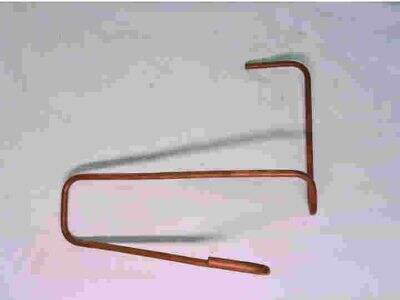

Because stainless steel pipe punching machine is so versatile, it can be used on a wide range of materials. This makes it suitable for various use cases. These machines can bore holes and cut shapes in pipes made of stainless steel, aluminum and even brass. This versatility makes machine implementation in factories a breeze, as it can be sure that the standards will match, regardless of the material being used.

Better yet, these machines can learn and evolve to tackle different jobs. They are technological tools that can drill holes and create shapes for pipes used in a variety of industries, including air conditioning, automotive and construction. Moreover, these machines can be programmed to create different patterns, so they are suitable for quickly setting up small or unique products. This flexibility form a significant benefit for factories already required to adapt to various customer requirements, as well as market availability and demand.

Saving Money and Time

Saving time and money are core reasons why almost all modern factories need stainless steel pipe punching machines. The automation of punching and cutting holes on metal pipes in factories will require fewer workers. This reduces labor costs, which are a major expense for many factories. The machines also minimize waste because they are designed to cut and punch precisely. This reduces the amount of waste material that must be discarded.

Also, these machines could work non-stop. And as they work for longer periods, they become more efficient, allowing factories to pump out more products in a shorter time period. In short stainless steel pipe punching machine is an important tool in modern factories. Not only do they help to keep operational costs to a minimum but also save on labor and waste and downtime, leading to a far more efficient production process in general.

Conclusion

Finally, the CUTTING MACHINE is a very important equipment in modern factories, especially for stainless steel pipes. They speed by easing work, are robust and stubborn, enhance factory functions, are versatile (able to perform a wide range of tasks), and are cost and time savers. Factories to produce more precisely according to customer specifications, save valuable resources, help save costs, improve product quality through continuous optimization of products. From assembly lines to complex manufacturing systems, these machines are critical to helping factories meet the needs of today’s fluid, high-speed production environments.