Are you putting in the hard yards working away IN your manufacturing company? Do you feel overworked on processes that could be simplified? For a quicker and easier method to produce your tubes look up automatic tube punching! So use Vedette's automated tube punching machine; it will ease your work, save you money and give you the best results! So, let us break down all the super fabulous things about automated tube punching which will help you churn out tons of products at a speedy pace.

Tube Punching: A pathway to eased production

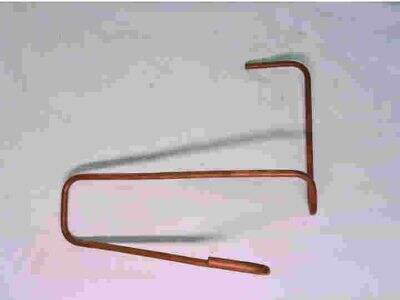

There is no metal tube shaping with hand tools anymore! Automated tube punching is a neat solution to simplify the process and reduce human error from making the piece by hand. We have this machine to cut and bend tubes to correct size and shape. It even labels the tubes for easy location and organization. So all your tubes, will be the exact same all done correctly with no error. It ensures the Safety of the workers as the machine does the difficult task and the heavy work is reduced and the chances of accidents goes down.

Improved Efficiency and Precision with Automated Tubing Punching

Vedette's automated tube punching machine is much faster and more accurate compared to punching it by hand. It can also work 24/7, allowing it to create more tubes in a shorter amount of time. This is highly beneficial for companies looking for high volume, fast tube production. Because the tech is smart enough to cater for many many different sizes and types of tubes. And, it saves material by minimizing waste so it helps you optimize your resources and save money.

Automated Carrier Punching: Cutting Cost

One of the most valuable processes in the sheet metal industry for saving costs on labor while improving production is automated tube punching. That would require fewer manpower to manage the material line and in another way make you spend, less every month to pay for workers. This is a major aid for any company looking to reduce expenses. It even uses less materials than traditional hand-cutting, which saves money in itself. And because it requires minimal maintenance, you can save on repair costs and keep your production running seamlessly.

Automating Tube Punching Process to Enhance Production

Vedette's machine doubles your production in many different ways. It can reduce production time by up to 75%, so you can fill orders faster, keeping your customers satisfied. This is really key for a good reputation, because the machine always produces high-quality products, regardless of who's operating it. This consistency also prevents errors that could occur when humans carry out the work, resulting in fewer mistakes and increased satisfaction. It also reduces downtime so you can recoup your money sooner and continue scaling your business.

Precision, Speed, and Lower Labor Costs

In manufacturing, accuracy is extremely important which is why our automated tube punching machine is able to get everything perfectly right on point. It was easy to adapt for different workloads -- just a few tubes for a LAMP test, or a small batch for a bigger, say, bioreactor test. There are numerous ways Vedette's machine will slash costs. Its employees use fewer workers, helps reduce wasted material, and is less expensive to operate. Such technology would be beneficial to manufacturers that require speed, quality, efficiency, and cost reductions.

In short, automated tube punching at Vedette is the right choice to make tube production easier, faster, and better for all involved. It's certainly more efficient and more precise than doing it yourself, so you can trust the results. Automated tube punching has many advantages like precision, flexibility, cost-saving and increased production in the process of your company. With Vedette's Automated Tube Punching Machine, Forget about the redundant work for hours and Say hello to quick, accurate, and intelligent machinery! Choosing this technology means you are taking the right step for your company’s long-term growth.