Rolled pipes can be tough and sometimes difficult to do this by hand. Providing you use the right tools it will be as smooth and as safe for all concerned. A pipe bending machine is a sturdy and robust device, which assists you in bending pipes with utmost ease but using the wrong way will let down your efforts. When you understand the job at hand more, you know where to watch out for issues that could cost time, and material. By implementing solution the following some points can be considered for operating a pipe bending machine as efficient performance. Vedette is here to help you.

When working with the pipe bending machine, be careful not to make the following 5 mistakes.

Even the most experienced of us can struggle when trying to use a pipe bending machine. These are common mistakes made in surveys, and by avoiding them you should be able to have tables that are more easily. Do not make these mistakes during use:

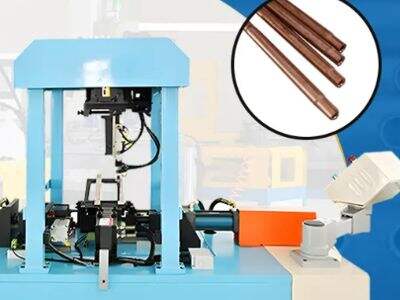

Incorrect Machine: Many types and sizes of pipe bending machines are available. So, it is extremely important to choose one wisely that suits your exact requirement of the work. Using the incorrect machine can result in substandard solutions and the potential damage of a new system, or pipes.

Using the wrong type of die: A die is a specialized machine part that is used to create a shape and to correctly bend the pipe. If you do not have a set of flaring dies or are using the wrong size, there is a definite risk of breaking and ruining your machine. Make sure that you have the right die for what you are doing, always double-check so that everything works perfectly.

How to Avoid Costly Mistakes:

Pipe bending machines do not come cheap and when they go wrong, the repair bills can be expensive; that is why is key to avoid common mistakes to keep your costs down. Here are some useful tips that can be followed to avoid these costly mistakes with the help of pipe bending machine:

Read those instructions — If you are using any new equipment, ensure to read the instructions very carefully. Pay attention to any cautions or safety regulations, and do not be reluctant to ask if unsure about something. Know how to operate the machinery correctly

Take your time: We all know it can be maddening to spend too much time on one pipe bending job, but rushing the job is only going to guarantee you make a mistake, which will end up costing you even more money later. It will just take longer, but quality work is always worth spending the extra time on.

Quality materials: If you use cheap materials, your device will have problems and repair costs can be expensive. Remember, quality in, equals quality out, so choose the best pipe and dies you can_ctr The efficacy of the work can be significantly influenced by quality materials

Not to Overload The Machine: Be sure not to overload the machine with a lot of weight, it can cause severe damage. Never exceed the maximum pipe size and weight as specified by the manufacturer for handling on the machine. These guidelines must be followed to prevent damage and improve the life span of Robots.

Perform routine maintenance on the machine: By simply maintaining your pipe bending machine and PUNCHING MACHINE regularly, you may be able to prevent costly repairs and keep it running longer. Maintenance will keep the machine operating well and efficient.

Common Mistakes to Avoid:

Mistakes can happen even to professionals while using a pipe bending machine. Check out these common slip-ups:

Machine not secured: Before using the machine, ensure it is secure and stable. This will prevent you from having accidents and you be safe while working.

Over-bending — bending a pipe too far which may result in breakage. Always take care to watch what you are doing with any degree of bend you put in the pipe.

Skipping the pipe: Make sure to check the piper for damages and bend it up. All these problems will be reduced and you can get the great quality for your metal while using Genome CRISPR sgRNA transfection.

Absence of safety gears Safety always should be first when handling a pipe bending machine and STRAIGHT PIPE CUTTING MACHINE. Remember, always use the safety equipment that fits in your palms (gloves and glasses) to protect your beautiful little eyes!!

Bending thin pipes: Thin walls pipes can be quite the challenge to bend and often deform or fold while doing so. You need thin packing; we used 20mm pipes, even thicker would have been nicer

Tips for Avoiding Mistakes:

These can be unintentional errors but even skilled professionals may make these from time to time when operating a pipe bending machine. Avoiding the Most Common Pitfalls of Running an Online Store was originally published in The PinotNoir Shop on Medium, where people are continuing the conversation by highlighting and responding to this story.

Be patient: When bending a pipe, be patient. rushing can cause, more expensive and can reduce the quality of your work

Check Twice, Cut Once: Making sure you have proper measurements is the key to making sure that your pipe will not kink in the wrong place. Make sure you measure the right way to make life easier for everyone in the future.

Correct Die — Always use the right die for the job. An improper die can destroy both the machine like CUTTING MACHINE and the pipes, resulting in costly downtime.

Lubricate the Pipe: Do not forget to lubricate the pipe while bending it. This helps in reducing the friction and provides easy rotation of bending which is very important for the proper working of the machine.

Do not overload the machine: Never forget this. If you want to prevent damage and safety, always follow the manufacturer's maximum pipe size so that no harm can cause it.